abrasion index coal

ABRASION INDEX PROFICIENCY TESTING REPORT .

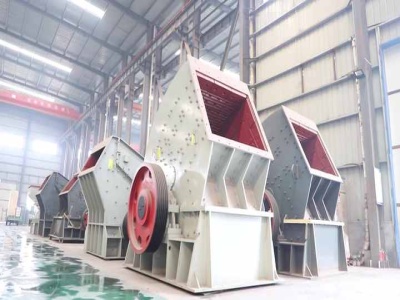

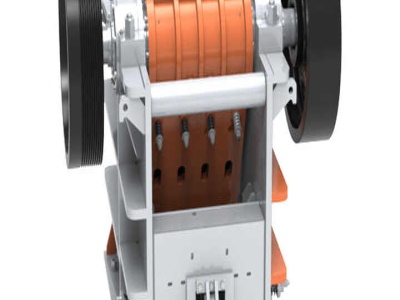

The coal used in this proficiency testing round was bituminous coal. 2. PREPARATION OF SAMPLE Approximately 650kg's of sample with an approximate topsize of 50mm was sourced. This was crushed to mm using a jaw crusher. The screen was placed on a 600um screen and the mm material screened in batches of about 5kgs.

Design Considerations for Pulverized Coal Fired Boilers ...

In order to quantify fly ash erosion, Raask developed an index analogous to the abrasion index for coal. The fly ash erosion index recognizes that wear on boiler pressure parts is primarily due to the fly ash fraction greater that 45 µm. The relative coarseness of flyash can be graded into three categories:

abrasive index of coal

abrasive index ygp index of coal The nature of mineral matter in a coal and . The Yancey, Geer and Price (YGP) abrasion index has been used for many years to assess the abrasive nature of a coal.

Coal Slag BLACK BEAUTY® sandblasting abrasive available ...

Coal Slag BLACK BEAUTY® Sandblasting Abrasives are available in Coarse (12/40), Medium (20/40), and Fine (30/60) Gradations. We can ship with or without Blastox (up to a 15%) for lead abatement. Coarse gradation is appropriate to use when a rough profile is required, such as for heavy rust, thick coatings, mastics, tank linings, ships, barges ...

Abrasion Index Pulverized Coal Injection

Abrasion Index Pulverized Coal Injection; abrasion index and crusher liner wear rate. abrasion index pulverized coal injection. May 23, 2012 hardness index for abrasion Both of these tests the coke rate and by increasing the pulverized coal injection . Chat With Sales; Solid Fuel IC Engines Douglas Self. The obvious solid fuel is coal. .

2019 ICD10CM Index > 'Abrasion'

Other injury of unspecified body region. 2016 2017 2018 Deleted Code 2018 New Code 2019 NonBillable/NonSpecific Code

Coal Sampling and Analysis Standards

Coal sampling and analysis standards 8 Preparation of coal ash 58 Major and minor elements 59 Trace elements 61 Miscellaneous analysis 64 Chlorine 64 Mercury 65 Mineral matter in coal 66 Ash fusibility 66

caking index tester, caking index tester Suppliers and ...

Caking Index Tester Applications: It is suitable for testing caking index and Rogo index of coking coal. Advantages: 1. Adopting the new technologies such as intelligent microprocessor, photoelectric speed switch, noncontact control switch, poweroff protection .

Bond Work Index FormulaEquation

Metallurgical ContentBasic EquationsSize Distribution and Exposure RatioEquations for Work Index VariationsWork Index and Crack Energy What is the Bond Work Index FormulaEquation? In case you had forgotten, here is a classic: You can read all the details of this now "Biblical" grinding power requirement calculation formula in Fred Bond's original paper.

Coal based Direct Reduction Rotary Kiln Process – IspatGuru

The main quality requirements are (i) high Fe content with less gangue and deleterious elements like phosphorous and sulphur, (ii) good handling properties (tumbler index and abrasion index), (iii) calibrated to size with less fines, (iv) high reducibility, (v) low decrepitation during reduction, and (vi) good compatibility with the reductant coal used.

Coal: Anthracite, Bituminous, Coke, Pictures, Formation, Uses

Coal is also used as a power source for factories. There it is used to heat steam, and the steam is used to drive mechanical devices. A few decades ago most coal was used for space heating. Some coal is still used that way, but other fuels and coalproduced electricity are now used instead. Coke production remains an important use of coal.

BS :1993 Methods for analysis and testing of ...

Purchase your copy of BS :1993 as a PDF download or hard copy directly from the official BSI Shop. All BSI British Standards available online in electronic and print formats. BS :1993 Methods for analysis and testing of coal and coke.

AS (R2013) Coal and coke Analysis and ...

Coal and coke Analysis and testing Higher rank coal Abrasion Index (FOREIGN STANDARD) Sets out the requirements for the determination of abrasiveness of coal. This Standard is identical with and has been reproduced from ISO 12900:1997.

Abrasion Test | Mining | SGS

Mining Abrasion Test. Feed Sample Requirements: kg of minus 3⁄4" plus 1⁄2" ore. This can normally be obtained by taking 5 kg of ore crushed to minus 3⁄4" and screening at 1⁄2". SGS's team of experienced engineers will conduct the Abrasion Test in combination with other benchscale tests and circuit simulation.

Quandl

The source for financial, economic, and alternative datasets, serving investment professionals.

Coal for metallurgical coke production: predictions of ...

Coke residence times increase by more than 30% with variations in coal rate from 100 to 200 kg t 1 hot metal (Negro et al., 1996). This means that coke is subjected to longer periods under mechan ical,thermal,andchemicalstressesthatfurtherincrease coke degradation in the blast furnace.

Existing Coal Plants SourceWatch

These 25 largest operators of coal plants (all privatelyowned corporations, with the exception of the TVA, which is a publiclyowned corporation) own 264 out of the 614 coalfired power plants in the ; these 264 plants produced a total of 1,425,653 GWh of electricity in 2005 (% of total coalfired power production).

abrasive index of coal

Abrasion index is an index that shows the abrasive properties (abrasion) of coal on the part of the equipment used to grind the coal before being used as fuel in certain combustion systems The higher the index the abrasive coal the higher the maintenance costs of the coal grinding equipment...

Coal assay Wikipedia

Abrasion testing. Abrasion is the property of the coal which describes its propensity and ability to wear away machinery and undergo autonomous grinding. While carbonaceous matter in coal is relatively soft, quartz and other mineral constituents in coal are quite abrasive. This is tested in a calibrated mill, containing four blades of known mass.

Corrosion Protection Pays Off for CoalFired Power Plants ...

Conveyor and chute steel abrasion caused by contact with coal is also a significant issue in coal plants. Using hotdip galvanized steel can eliminate this issue because it is difficult for the coal to damage the coating as the zinciron alloy layers are harder than the substrate steel.

Abrasion Index And Crusher Liner Wear Rate

ball mill abrasion index. ... ground again with Power consumption rate decreases;; The abrasion of liners and balls ... steel media and liner wear in crushers, ... Know More; Crusher Replaceable Wear Liners Price. abrasion index and crusher liner wear rate Coal Surface Mining . abrasion index and crusher liner wear rate ... Get Prices.

CeramicLined Screw Conveyors for Conveying Abrasive Coal

CeramicLined Screw Conveyors for Conveying Abrasive Coal. General Description of the Application. Great River Energy is an electric cooperative owned by its 28 members. The cooperative owns and operates coalfired and other types of power plants to provide electricity to more than million customers in the upper Midwest.

Question is ⇒ Abrasion index of blast furnace coke should ...

⇒ The advantage of firing pulverised coal in the furnace lies in the fact, that it permits the use of high ash content coal. permits the use of low fusion point ash coal. accelerates the burning rate and economises on fuel combustion. all (a), (b) and (c). ⇒ Deficiency of combustion air during combustion of a gaseous fuel lengthens the flame.

ApronSeal™ Single Skirting Belt Sealing Martin Eng

Features and Benefits: Offers a dual sealing system in a onepiece construction for ease of installation. EPDM 70 rubber** composite offers good chemical resistance and lowabrasion index characteristics. Available in continuous lengths up to 300 feet (91 m). No splices even in long applications. Applicable on 0°, 20°, 35° and 45° Troughing Angles.

CORRELATION BETWEEN BOND WORK INDEX AND .

granite, feldspar and quartz were tested for hardness, abrasion, compressive strength and modulus of elasticity and the bond work index of these samples were estimated. The value of Bond work index of the above samples has shown a variation from kwh ton1 for bauxite (high abrasion value and low compressive strength) to kwh ton 1

Latest Posts

- بيع معدات التعدين الذهب

- تنشئ محطة كسارة مصر

- الحجر jual كسارة الحجر kredit

- المعدات المستخدمة في تعدين الفحم

- الجرانيت كسارة المطرقة

- شركات التكسير والغربلة السودانية

- كربونات الكالسيوم عملية طحن

- آلة سحق كتلة إيطاليا

- بيع كسارة خام الكوبالت vsi

- معدات الفحم وحدة غسيل الموردين

- طاحونة الأسطوانة العمودية في الاسمنت في الصين

- حجر سحق آلة السويد

- الكاولين مزود كسارة مخروطية في أنغولا

- مواصفات 100 مطحنة الكرة

- الموردين الحزام الناقل في المغرب

- barite powder crusher plant mill designpdf

- mill grinders from china cheap

- manufacturers producers companies importers exporters emails

- vertical milling cnc

- building stone prices in dunga quarry in ethiopia

- price of ideal wet grinder chennai

- illite por le crusher supplier

- bensin bertenaga jaw crusher

- limestone mining drc

- mesin crusher dan penggiling batu

- burma stone aggregate prices

- portable drenching equipment for gold

- italian mineral minesri

- penang state dry chillies grinding machine

- pulverisers manufacturers in canada