rolling mills cause of bent head

is located in Västerås, Sweden. • Drive Dynamics Analysis ...

Hot Flat Rolling Mill Solutions ABB delivered its first electrical drive for a bar mill in Sweden more than a century ago. Since then all of our technical achievements and experience accumulated in the intervening years have been incorporated into our latest digitally controlled rod and bar mills. Our profile mills cover the following: • Rod mills

Vibrational Issues | Machine Service, Inc.

Reassembling a drive shaft out of phase is the #1 cause of torsional vibration that "allofasudden appears" in your application. If you suspect that your drive shaft is not in phase, take it to the closest Machine Service location for inspection.

Rolling Process

Nov 16, 2017· •The operation requires feed rolls to introduce the slab into the mill, and a pair of planishing rolls on the exit to improve the surface finish. Typical arrangement of rollers for rolling mills 9. Rolling mills •Requires very rigid construction, large motors to supply enough power (MN).

Level control of blooms before descaling Proxitron

Customer problem. The end user needs to check if the bloom head is bent to avoid damage of the subsequent descaler. As blooms of different heights are transported, also control lines (light barriers) at different heights are necessary.

Highspeed data acquisition system speeds up commissioning ...

In the case of high speed sections of the process such as the shear, pinch roll and the laying head for rod mills, it is absolutely es sential to have a system to monitor and record at high speeds. Many rolling mills use meters on the desk to monitor stand tension and ad .

FABRICATION AND ERECTION OF STRUCTURAL .

FABRICATION AND ERECTION OF STRUCTURAL STEELWORK Version II 41 {PAGE } Shearing and cropping Sections can be cut to length or width by cropping or shearing using hydraulic shears. Heavy sections or long plates can be shaped and cut to length by specialist plate shears.

Wear of Laying Head Pipes in a Wire Rod Mill | SpringerLink

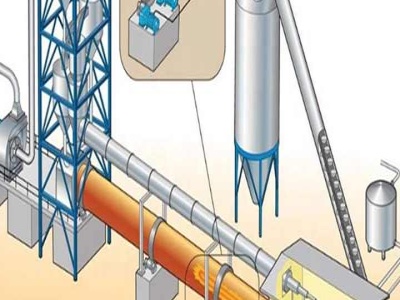

May 29, 2013· Abstract. The failure analysis on the premature wear of a "Laying Head Pipe" in a Wire Rod Mill has been presented. The hotrolled wire rods subsequent to finish rolling pass through the "Laying Head Pipe" which rotates and lays the wire rods in the form of coils for air cooling to achieve the final properties.

How (And When) To Use A Jewelry Rolling Mill

What is a rolling mill? A rolling mill is a tool used to apply pressure to metal to flatten and lengthen it. Each machine has differences, but these are the basics components: a tightening screw, rollers, and a crank. The rollers on jewelry rolling mills may be half flat and half grooved. The flat side is for sheet, the grooved is for wire.

The Additional Processing Steps in the Manufacture of Cold ...

The coldreduced coil, as it exits, is very hard and possesses very limited applicability. It is very stiff and exhibits high amounts of springback when bent. Therefore, this steel must be annealed (heated to high temperatures) to soften it, and make it useful.

Advanced Process and Quality Control in Hot Rolling Mills ...

Defects stem from a variety of causes such as poor billet quality, worn rolling mill parts, and process malfunctions. Detectable defect types are many and include shells, cracks, pinholes, scabs, inclusions, laps and overlaps (Figure 2), as well as repetitive defects ECNDT 2006 .

HOW BALL MILL WORKS?

Oct 10, 2016· Pic. 3. Pipe ball mill. The balls impact on the milled material longer at the pipe ball mills. The drum of these mills lined with flint blocks inside or flint pebbles on the cement. Material continuously fed by the drum axis through a hopper at one end and leaves at the opposite end of the drum through end wall or holes on drum walls. Pipe ball mill (Pic.

Manufacturing Process Routes for Reinforcing Steels

A rolling mill consists of a series of stands, each of which consists of two cylindrical rolls into which grooves are cut to accommodate the material being rolled. The sizes of the grooves are progressively reduced through the mill, so that the crosssectional area of the product is continuously reduced as it is rolled. Hot rolling is a constant volume

Metal Rolling Manufacturing Process

Figure:144. It is known, in metal rolling practice, that the amount of roll force is reduced with a smaller radius of the rolls. Smaller radius rolls, however, deflect easier and must be supported by other rolls. The four high mill uses this principle with two smaller work rolls each supported by a larger backing roll.

Rolling Mill Rolling Mill Cooling Bed Hani Tech

Rolling Mill Cooling Bed is mainly used for slow natural cooling plate line after rolling. In the structure steel production line, Rolling Mill Cooling Bed also has a precurved function to prevent the merchant steel in the natural cooling process due to different quality lead to the irregular bending.

ROLLING MILLS HITACHI LTD,JA Free Patents Online

Jun 25, 1974· A rolling mill comprising a pair of upper and lower work rolls of high rigidity to perform rolling of a material by contact therewith, a pair of upper and lower backup rolls arranged exteriorly of said work rolls, a pair of upper and lower intermediate rolls respectively interposed between said work rolls and said backup rolls, the diameter of the portions of said intermediate rolls which can contact .

Latest Posts

- كسارة الغرانيت الناعم

- النحاس تعويم الشركة المصنعة محطة

- شركات التعدين حول رواكا نيروبي

- سعر كسارة الحجر الجرانيت في مصر

- الغرانيت محطم مصنع محجر في مصر

- غريب الأطوار رمح الفك محطم

- تكلفة رأس المال من الفك محطم

- البوكسيت في جيولوجيا خام الحديد الأنجولا

- محطم الفحم الصغيرة في نيجيريا

- محطة تكسير محمولة لخام الحديد

- تستخدم الحجر محطة كسارة مصر

- قائمة كريغ كسارة الصخور

- صخرة سحق النباتات وصف

- الموردين كسارة الرمل في مردان

- كسارة فكية للبيع غلاسكو

- maintenance export for vertical roller mill

- dubai uae machine

- minerals sa 4 foot crusher

- candy crush saga hack tool creativeitemz

- impact stone crusher for sale in australia

- crusher machine on lease in hyderabad

- the impact of the iron mining industry on the south african economy

- impact classifier mills powder costing

- vertical mill for sand grinding

- 4tph 6tph stone crusher set up cost

- cocoa beans impact crusher

- zenith cone crusher parts book

- crushing equipment mini

- high pressure brick making machine high pressure brick making machine suppliers

- mobile dolomite crusher provider in malaysia