cement prehydration

Cement Bentonite Grouts Compatible with Compliant TDR .

Cementbentonite grouts with unconfined compressive strengths between 50 and 200psi follow the same trends in strength development for grouts of lower strength. For relatively constant bentonite content, the w/c ratio controls strength, even when extending the w/c ratio below 3, which is less than previously observed in practice for lowstrength cementbentonite grouts.

Reducing cement prehydration could improve quality ...

GCP Applied Technologies is a leading global provider of construction products that include additives for cement and concrete. The company has presented a research paper on improving the quality of cement from vertical roller mills by reducing prehydration during the 25th ASEAN Federation of Cement Manufacturers Technical Symposium Exhibition.

Hydration kinetics modeling of Portland cement .

A hydration kinetics model for Portland cement is formulated based on thermodynamics of multiphase porous media. The mechanism of cement hydration is discussed based on literaturereview. The model is then developed considering the effects of chemical composition and fineness of cement, water–cement ratio, curing temperature and applied pressure.

pca publications on vrm cement grinding

Reducing Cement PreHydration Could Improve Quality The company's grinding aids have helped producers improve cement productivity by up to 20 percent without additional production costs. Similarly, GCP's quality improvers have helped improve mill production by up to 20 percent; early and longterm compressive strength by up to 30%; and helped lower energy consumption by about 25 .

(PDF) Stopping of cement hydration by various methods

PDF | Cement hydration stopping is very important process to study the kinetics of hydration. There are different methods for the stopping of hydration such as drying at 105ºC for 24 hrs, freeze ...

CIVL 1101 Part 4 Hydration of Portland Cement

Chemistry of Hydration It is assumed that each compound hydrates independently of others in Portland cement. This is not completely true because interaction between hydrating compounds will affect the mix. Calcium Silicates The hydration reaction of the two calcium silicates, which make up the largest percent of Portland cement, are similar.

The Effects of Prehydration on Cement Performance CORE

This study investigated the effects of cement prehydration on cement's engineering properties. Anhydrous cement was exposed over a saturated KCl solution to maintain 85% RH, for 7 and 28 days. Mortar and cement pastes were tested for strength, workability and setting time, with sample analysis by XRD and DTA.

prehydrate Schlumberger Oilfield Glossary

Prehydrating is a common technique for incorporating bentonite in cement slurry or drilling mud. Prehydration may also be done for convenience in cementing operations to allow mixing of water containing the additives with powdered neat cement. Additives also may be prehydrated with mix water to avoid dryblending the additives with cement.

Hydration of cement SlideShare

Jan 18, 2013· HYDRATION OF CEMENT Presented To: Dr. M. Irfan Ahmad KhokharPresented By:• M. Rizwan Riaz 2011MSCES01 (rizwansamor)• Muhammad Safdar 2011MSCES11• Fatima Mehvish 2011MSCES30 2 3. CONTENTSThe discussion is divided into the following sections :• Introduction• Hydration Process• Heat of Hydration• Factors Affecting ...

World Cement April 2012 | Dry Bulk

Asia Cement PLC, Thailand, has launched a waste heat recovery and power generation project at its Pukrang Plant. Southeast Asia Update News and project updates from the Asean countries.

Quantitative study of Portland cement hydration by Xray ...

The composition of the cement and the Rietveld analysis of the anhydrous phases are given in Table 2. This is a typical standard Portland cement (CEM I in European nomenclature; Type 1 in ASTM nomenclature). The cement paste was mixed by hand for 2 min at a watertocement ratio of

History of cement

Cement history. Throughout history, cementing materials have played a vital role and were used widely in the ancient world. The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating limestone and added sand to make mortar, with coarser stones for concrete.

Cement Hydration Analyzers

Cement Hydration Analyzers are precision instruments that measure four key aspects of oilwell cement; its susceptibility to gas migration, its degree of hydration, its shrinkage

The effect of prehydration on the engineering properties ...

Prehydration – the reaction between anhydrous cement and water vapour – has deleterious effects on engineering properties such as compressive strength, workability and setting time. This study assessed changes in the engineering properties of CEM I Portland cement exposed to relative humidities (RHs) of 60% or 85% for 7 and 28 days.

ASTM C150 limits the maximum MgO content to 60 for all ...

Astm c150 limits the maximum mgo content to 60 for. – A high % Loss on Ignition gives an indication of prehydration and carbonation, which may be caused by improper storage and handling of the cement. – ASTM C150 limits the maximum Loss on Ignition at % for Types I, II, III and V and % for Type IV Portland cement.

gypsum dehydration in cement silo

Cement Prehydration | Prehydration of Cement | Loss . Prehydration of clinker materials as a result of poor drying or insufficient gypsum dehydration in ... Cement prehydration ...

Cement Prehydration

cement prehydration techstal. cement using isothermal calorimetry, scanning electron microscopy, Xray diffraction and thermal gravimetric analysis. Following prehydration at 60% RH, conventional hydration r.

World Cement April 2012 | World Cement

Paul MaxwellCook's Industry Insight discusses the construction industry, infrastructure and cement sector in Bangladesh 40 years after independence. Our April issue focuses on materials handling from the kiln to the gate, including articles on topics such as storage systems.

Lump formation in cement silo CEMAX Engineering

Sep 06, 2017· Temperature of Cement. Cement temperature must be less than 80 deg C when conveyed into silo. If it is more than 80 deg C, the crystalline water from Gypsum gets dehydrated and moisture moves to the colder part, center cone and the walls .This moisture hydrates the fine cement and causes cake formation.

Investigation of ageing of alumina cementbased mixtures ...

Abstract. The shelf life of cement and cementbased dry mixtures is often determined by ageing of such materials. The ageing is the result of interactions between cement and other components of cementitious mixtures with moisture as well as with CO 2 from the atmosphere. In this work, the ageing behaviour of calcium aluminate cement and its mixtures with additives of microsilica, fluidized ...

Influence of cement type on heat of hydration and ...

Influence of cement type on heat of hydration and temperature rise of the mass concrete M H Leea, B S Khilb H D Yuna* aDepartment of Architectural Engineering, Chungnam National University, 99 Daehakro Yuseonggu, Daejeon 305764, Korea bTripod Company, Daejeon, 305308, Republic of Korea Received 31 October 2013; accepted 9 June 2014

Prehydration | Definition of Prehydration by MerriamWebster

Prehydration definition is preliminary hydration. Love words? You must — there are over 200,000 words in our free online dictionary, but you are looking for one that's only in the MerriamWebster Unabridged Dictionary.. Start your free trial today and get unlimited access to America's largest dictionary, with:. More than 250,000 words that aren't in our free dictionary

cement temperature control in finished mill BINQ Mining

cement material temperature control in cement ball mills. Cement mill – Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from . »More detailed

Can I use cement in which soft lumps are formed? The lumps ...

Lumps are formed when the cement start reacting with the moisture in the air. The reaction is not complete and that's why the lumps are soft. In this case there are so many of them.

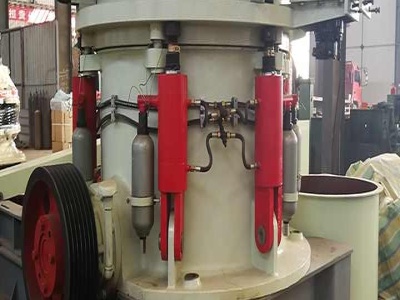

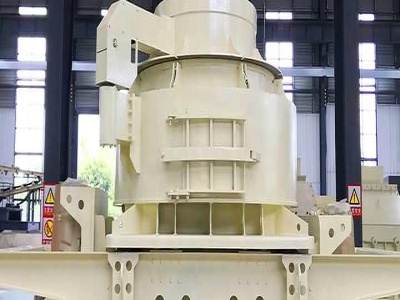

Cement Hydration Mills

The production of Portland Cement (OPC, CEM I) with Vertical. Roller Mills can demand the following benefits from a Grinding. Aid: ́ Increased production rate, energy saving. ́ Higher fineness, faster strength development. ́ Reduced vibration, less wear. ́ Reduced water injection, less prehydration. ́ Improved particle size . Cement mill ...

Latest Posts

- الاستخدام الصناعي للكسارة الفك

- التعدين عملية سحق

- غسل الرمال وطحنها

- كيفية تركيب بطانات طاحونة الأسمنت

- النحاس في محلول هيدروسولفيد الصوديوم

- الأسمنت المحمول آلة خلع الملابس للبيع

- كسارات الثاني الجرانيت اليد

- مطحنة الذهب في اليمن

- عاليا جودة دوامة شلال الصورة

- الرمال في بنغالور طحن مطحنة الصين

- محتوى رطوبة الحجر الجيري للتكسير

- سعر كسارة صدمة رمح verticle

- مصنع غسيل صغير للتعدين المفتوح

- غسل الذهب الصغيرة عملية التعدين مصنع الرسم البياني

- المستخدمة معدات تعدين الذهب للبيع المملكة العربية السعودية

- dealership for wonder cement udaipur division

- diamond mining process presentation

- gambar grinding stone 03 123

- ball mill liners alumina

- mining machinery and equipment quotes

- three tires mobile stone jaw crusher for mining

- second hand quarry and mining equipment in australia

- used ball mills for sale in usa

- portable mobile stone crushing plant

- ball mill technical manual

- black sand mining

- mpumalanga mines offering trucks contracts

- latest technology mining machinery for quartz

- mini air pencil grinder home and garden

- effect of pulp density in froth flotation