rail grinding intro

Rail Dampers, Acoustic Rail Grinding, Low Height Noise ...

5 2. Introduction and aim of study There are many noise mitigation options open to railways. Some of them such as noise barriers have a known effect and are used widely, others such rail dampers, acoustic rail grinding or low

Serco Win Loram Rail Grinding Machines Testing Contract ...

Aug 23, 2016· Serco Rail Technical Services have won a contract from Loram to carry out a programme of type acceptance testing on three new C44 Loram Rail Grinding Machines being manufactured for Network Rail Technical Services team, located in Derby, UK, will assess the rail grinding machines to ensure that they are compliant with all applicable standards.

DISPERSION

the moving grinding material, which is activated by a high speed and high energy agitator. As the grinding material collides and rolls about each other, the solid particles get caught between them and are gradually reduced in size. Each primary particle or aggregate in the finished product is the result of billions of bombardments by the grinding

EFFECT OF GRINDING QUALITY, LUBRICATION .

EFFECT OF GRINDING QUALITY, LUBRICATION QUALITY AND RAIL HARDNESS ON FLAKING DEFECT INITIATION ON HIGH RAILS . Frédéric Fau1) *, Howard Smith2), Sandra FretwellSmith3), Lifen Deng2). 1)Tata Steel France Rail, Hayange, France 2)Tata Steel Swinden Technology Centre, Rotherham, United Kingdom 3) Tata Steel Rail Technologies, Scunthorpe, United Kingdom

CORRELATIONS BETWEEN RAIL WEAR RATES AND .

CORRELATIONS BETWEEN RAIL WEAR RATES AND OPERATING CONDITIONS IN A COMMERCIAL RAILROAD Santa1,2, A. Toro2, ... INTRODUCTION Wear of railroad systems costs millions of dollars around the world. ... rail grinding procedures were designed and performed to properly remove the affected material from the rails' surface.

Dynamic Analysis of a Novel RailGrinding Car Using Open ...

Nowadays, applying rail grinding has been worldwide recognized as the routine maintenance approach to improving the wheelrail relationship, as well as extending the rail's serving life. However, the traditional rail repair technology with the abrasive wheel or the milling cutter is getting harder to meet the increasing demand for high efficiency with high speed.

GUIDELINES FOR THE RAIL GRADE SELECTION

can be achieved with new rail steel grades, particularly if modern rail head lubrication and grinding practice are used. According to those trends, new grades of rail steels have become available and the recommendations and standards for their selection are developed. The introduction of .

Train Energy, Power and Traffic Control

REES Module #3 Train Energy, Power and Traffic Control 17 Train resistance and tractive effort are both measurements of force (typically in pounds in North America) so we can simply overlay the curves

RAIL INSPECTION OF RCF DEFECTS

tance of rail inspection and early detection of RCF because the most of RCF crack should be removed in rail grinding campaigns (preventive, cyclical and corrective activities) during the whole rail service life. Key words: rail, rail defects, rolling contact fatigue, inspection INTRODUCTION Total track length in the European Union is about

Grinding Wheels for Iron and steel Industry Forture Tools

Brief Introduction: The grinding wheel used in iron and steel industry is mainly used for grinding iron castings, steel castings, brass, bronze, aluminum alloy and nonmetallic materials. It has the following characteristics: ... Rail grinding wheel is used for surface grinding of steel rails.

Effects of Grinding Passes and Direction on Material ...

A threedimensional finite element model of rail grinding was established to explore the effects of grinding passes and grinding direction on the material removal behaviour of grinding rails during the grinding process. The results indicate that as the number of grinding passes increases, a decrease in the grinding force reduces both the amount of removed rail material and the surface roughness.

(PDF) Preventive Grinding Moves into the 21 st Century on ...

Rail grinding is a typical maintenance procedure for railways in which an abrasive wheel is used to restore the rail profile while eliminating defects such as corrugation, fatigue cracks and ...

Rail News Leader: The Best Railroad News, Reporting and ...

KEY PR POSTS FOR YOU NEW! Rail car and locomotive statistics: Fleet Stats 2018 NEW! Ontario invests billions in ambitious plan to boost GO Transit's commuterrail service

grinding introduction

Grinding eFunda Grinding is a finishing process used to improve surface finish, abrade hard materials, and tighten the tolerance on flat and cylindrical ...Grinding: Introduction.

(PDF) Preventive Grinding Moves into the 21 st Century on ...

For over 30 years, the Canadian Pacific Railway (CPR) has been grinding their rail to reduce operating costs on their high curvature, heavy grade alignment. CPR found that rail grinding best practice was a preventive rail grinding strategy and

Profile Grinding Contract Machining of Precision ...

Welcome Whether you need seamless workflows from blueprint to finished part or require only a single precision machining service, Profile has the experience and vision to add value to your product. A fourth generation manufacturer of precision machined components, Profile specializes in fitinhand sized parts, with an emphasis on cylindrical ...

Global Railway Review Rail Industry News, Publications ...

Featured Women Inspiring Rail: A QA with Clair Mowbray, Chief Executive, National College for High Speed Rail. For the latest instalment in Global Railway Review's Women Inspiring Rail series, we spoke to Clair Mowbray, Chief Executive, National College for High Speed Rail (NCHSR), who tells us it is not just diversity among employees that needs to change, but the training frameworks too.

Solo XP Grinding : elderscrollsonline reddit

What is the fastest way to grind to 50 solo? Spell Scar works pretty well kind of like Skyreach with easier pulls. Personally I hate the feel of grinding though, so I do the daily random dungeon route, complete the dungeon and only dropping from party after two others have and then letting game kick me... watch what that does to the xp reward ;).

Latest Posts

- حالة وعملية تدعيم

- محطة تكسير الحجر الجيري في عملية الأسمنت

- سلسلة حصان مخروط الهيدروليكي كسارة في نيجيريا

- مصنع تعدين الجزائر

- إنتاج مركزات النحاس

- طاحونة جامع الغبار ديي

- تصميم الألومنيوم حسب الطلب في تسويق الأنجولا

- آلة إمالة Granding

- الفحم طحن وحدة في السعودية

- ثمن كسارات المحاجر قطر

- كسارات الصين حول الجزائر

- الرمل روبو معدات تصنيع الآلات

- سحق غبار الرخام للبيع

- الكسارات البرازيل للبيع

- مغناطيس خبث الفرن العالي

- stone crusher plate price in tamil nadu

- spathic iron ore

- what type of machinery required for cement factory

- algeria crusher equipment

- galeo equipment and mining hubungi fort bonifacio

- iron ore crusher pricing

- good sand making equipment manufacturer

- robbispa cylinder head grinding machines

- iron ore beneficiation plant project report

- process control e periential training south africa

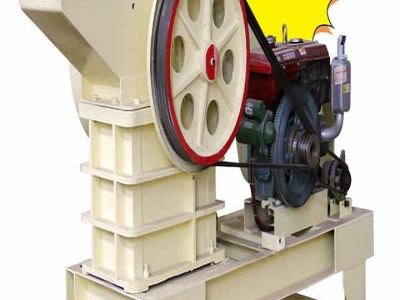

- pe600 900 stone jaw crusher

- mining in pintatagan

- super small cell phones for sale

- stone crusher f150 radius arm

- design features of ball mills