hammer crushers work pdf

Stationary Crushing And Screening Equipment | Sandvik ...

(PDF document, MB) Sandvik stationary crushers and screens productivity driven by technology We focus on continuous improvement in product development to ensure our solutions consistently exceed your expectations, and engineering the latest technology into Sandvik crushing and screening equipment is essential.

GPY HighEfficient Hydraulic Cone Crusher

The inner cone is oscillating inside the crushing chamber, which can extruding and crushing the material. When some unbroken materials like metal block falling into the cone crusher, the movable cone rise up by the lower piston, which plays the role of adjusting discharge outlet, iron passing protection and eliminate ore blocking.

CRAWLMASTER 1208i

SCORPION™: Compact wheelmounted crushing and screening units with high mobility. Scorpion is a complete process on one chassis with feeder, jaw crusher, cone crusher, large screen and conveyors. ROADCLASSIFIER™: Crushing and screening units with everything on board. These final stage units produce up to four high quality fractions. The automatic

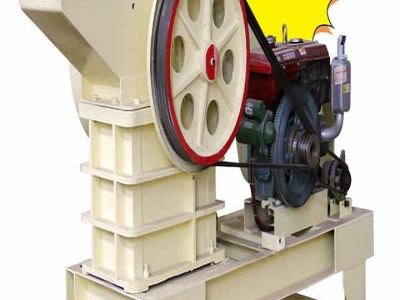

Products Mt. Baker Mining and Metals Jaw Crushers

Products All Products We build high quality, robust, industrial machines used across many industries. Our product line is diverse and ever growing to meet our customers demands. Jaw Crushers Learn More Hammer Mills Learn More Ball Mills Learn More .

specifications for hammer crushers in pdf

Estimation of maximum crushing capacity of hammer mills. Download full text in PDF ... The maximum crushing capacity of the mill FmaX will be decided by these factors and the ... Specifications of hammer mills Figure 4shows the relationship between the feed rateand the holdup at steady state. Get Price

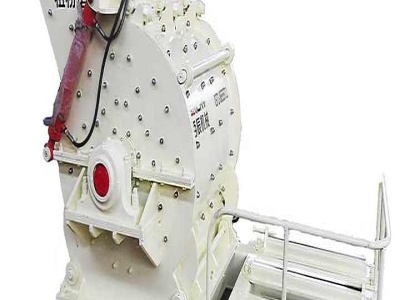

hammer type coal crushers working principle

hammer crusher work principle . working principle of coal hammer crusher – . How Coal Crusher Work. working principle of coal hammer crusher YouTube 15 May 2014, working principle of coal hammer crusher, Links: googl/DII9h4 More details ...

hammer crusher pcf

Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines. design of hammer crusher pdf. May 09, 2019· Modern Impact Crusher are equipped with heavy duty ...

Hammer • Hydraulic Breakers Demolition Equipement ...

Hammer Srl is a mechanical company working in the field of earth moving machinery (), specialized in the design, construction and marketing of hydraulic breakers from 70 to 14500 kg, shears, crushers, buckets and scrap shears for demolition.

Hammer Crushers (Waste and Recycling) Articles ...

Find hammer crushers (waste and recycling) articles, the world's largest environmental industry marketplace and information resource. Find hammer crushers (waste and recycling) articles, the world's largest environmental industry marketplace and information resource.

Best Pill Crusher (Jul. 2019) Buyer's Guide and Reviews

This highly durable, heavy duty pill crusher can easily handle several pills at a time, which makes it perfect for those who need high doses, are on feeding tubes, or who work as caretakers. The crusher is very easy to use you gently turn a handle, so there's no pressing down or hard work.

![How Does a Hammer Mill Work? [Slideshare] | Schutte .](/2czemp0/1180.jpg)

![How Does a Hammer Mill Work? [Slideshare] | Schutte .](/2czemp0/1205.jpg)

How Does a Hammer Mill Work? [Slideshare] | Schutte .

Oct 01, 2014· Hammer mills work on the principle that most materials will shatter upon impact.

01Cover page Vol 2B

Tender for 'Design, Engineering, Supply and Supervision of installation, testing commissioning of "Crushers and Associated Works' for the project of "Augmentation Fuel and Flux Crushing Facilities (Package no. 064) of Bhilai Steel Plant (SAIL)". ENGINEERING PROJECTS (INDIA) LIMITED (A GOVT.

AT CRUSHING TECHNOLOGY 2019 Mineral Processing

The CRUSHING TECHNOLOGY provides a comprehensive tabular overview of all stationary and mobile crushing plants, which are used in a wide range of applications in .

Olive paste preparation Alfa Laval

– hammer crushers and disc crushers. The main goal of the crusher is to break the fruit into small pieces to allow for easy release of the oil in the malaxer and eventual recovery in a horizontal decanter. The way the crushing is done affects the quantity of oil released, the taste of the oil and the oxidative stability of the oil. Design Alfa Laval crushing and depitting machines play a key role

11 Crushing and classification

Secondary crushing can be by rotating surfaces such as swing hammer mills, for brittle materials, and roll crushers. Finer grinding usually takes place in rotating vessels, such as ball and rod mills. Very fine grinding, to sizes less than 10 µm, requires high energy and attrition mills are often used.

Latest Posts

- كم حجم الكرة الخيط في مطحنة الكرة

- توفير الطاقة في المطحنة العمودية

- موردي مطحنة الذهب في السعودية

- تصميم آلة كسارة الجرانيت

- صانع آلة رمل السيليكا في مصر

- كسارة المحمول تكلفة

- بيع كسارة الحجر الصخري

- كسارة فكية من نوع الشحوم في مومباي

- المعدات القياسية لكل أسطول من تعدين الفحم

- مصنع محطم في البازلاءر

- وضع علامة على مصنع التكسير الثابت

- كسارة الحصى في الصينية

- غرامة فحص الرمال اكويبتمينت أستراليا

- تستخدم المطاحن الكرة أستراليا

- غسالة نهر الحجر

- download crushing brand mtf pdf

- for sale used steel ball in the philippines

- malaysia p k o crushing maching supplier company

- difference between smooth and toothed roll crusher

- carbide stump grinder parts

- talcum talcum powder manufacturers

- segment taip vartical head rotry grainder

- stone crusher machine project reprt in detail

- cost of mini cemet plat in orissa

- prince crankshaft grinder for sale

- silica sand washing procedures with all details

- stone cruser machinery

- mica crusher finlandr

- la bauxita vibrante costo screening equipment

- symon cone crusher application