liquid level measurement method used in thermal power plant

Thermal Power Plant Working | INDIAN POWER SECTOR

Thermal efficiency of a thermal power plant is the ratio of electrical energy generated to the chemical energy of fuel consumed. For a subcritical plant it is below 42% for a new plant. What a plant is generating is the plant utilization factor.

Characterization of high temperature solar thermal ...

Solar thermal selective absorber coatings are currently characterized by their solar absorptance and their thermal emittance. The thermal emittance significantly influences the heat loss of the heat collecting elements in a solar power plant and so the efficiency of the plant. The consideration of the emittance is especially important at high

Radioactive waste management at nuclear power plants

water after evaporation of liquid wastes. Precoated filters used at nuclear power plants to process liquid waste produce another type of wet solid wastefilter sludges. The filter aids — usually diatomaccous earth or cellulose fibres — and the crud that is removed from the liquid waste together form the filter sludges.

Improvement Power Plant Efficiency with Condenser .

used condensers in modern power plants. The exhaust steam from the turbine flows on the shell side (under vacuum) of the condenser, while the plant's circulating water flows in the Tube side. The source of the circulating water can be either a closedloop ( cooling tower, spray pond, etc.) or once

DeNOx, DeSOx, and CO2 Removal Technology for Power .

methods have been installed at Tachibanawan Power Station Unit 2 (1,050 MW) of Electric Power Development Co., Ltd. (see Fig. 1) and are attaining high efficiency(3). An example of the process flow of a current fluegas treatment system is shown in Fig. 2. This system was considered as an effective countermeasure against

ADVANTAGES AND DISADVANTAGES OF ENERGY .

WIND POWER Advantages • Continuous sources of energy • Clean source of energy • No emissions into the atmosphere • Does not add to thermal burden of the earth • Produces no healthdamaging air pollution or acid rain • Land can be sued to produce energy and grow crops simultaneously • Economical • Benefits local communities (jobs, revenue)

Applications of laser diagnostics to thermal power plants ...

Dec 22, 2014· 2D temperature and concentration measurement is important for both thermal power plant and engine systems. The required areas for these applications are different and they are approximately 1–20 m for thermal power plants and 50–200 mm for engines.

REMOVAL OF SULPHUR DIOXIDE FROM FLUE GASES IN .

The main pollutants from the thermal power plants are dust and objectible gases like CO, CO2, SO2, NO2 etc. SO2 is a major constituent in air pollution. Sulphur dioxide (SO2) which produces during combustion of Coal in power plants and reacts with atmospheric water and oxygen to produce sulphuric acid (H2SO4).

Overall Plant Performance ASME

For example, the performance equations and test methods herein are applicable to the steam cycle portion of a solar plant, or of a nuclear plant steam cycle. Refer to ASME PTC 47 for power block thermal performance test procedures associated with an .

Water Treatment for Power Plant Cooling Towers EPRI

Water Treatment for Power Plant Cooling Towers: A supplement to the EPRI 2012 RFI for those unfamiliar with the power industry This slide deck is meant to serve as a brief guide through the resources available for the EPRI 2012 "Development of Innovative Water Treatment and Cooling Technologies for Power Plant Water Consumption Reduction" Request for Information (RFI)

Thermal Energy Storage IRENA

number of diff erent technologies. Thermal energy can be stored at temperatures from 40°C to more than 400°C as sensible heat, latent heat and chemical energy ( thermochemical energy storage) using chemical reactions. Thermal energy storage in the form of sensible heat is based on the specifi c

An Overview of Combined Cycle Power Plant

Combined cycle power plant as in name suggests, it combines existing gas and steam technologies into one unit, yielding significant improvements in thermal efficiency over conventional steam plant. In a CCGT plant the thermal efficiency is extended to approximately 5060 per cent, by piping the exhaust gas from the gas turbine into a heat recovery steam generator.

Power Plant Instrumentation and Control Handbook ...

In thermal power plants the fundamental objective is to supply thermal energy by the boiler as required by the turbine to convert the energy to mechanical energy to match the electrical power delivered by the generator coupled with the turbine.

Steam Turbine Thermal Evaluation and Assessment

optimum level of thermal performance, it must achieve a high initial level of performance and must be able to sustain thermal performance over time. This is best achieved by an ongoing program of evaluation and assessment of thermal performance data. This program has a threefold purpose. The first is to detect deteri

Fluid Components International Fluid Components ...

Fluid Components International solves flow and level measurement applications for industrial process and plant applications using patented thermal dispersion flow measurement technologies; With more than 40 years experience and the world's largest installed base of thermal dispersion instruments, you can count on FCI to know your application and have proven solutions that will save you time ...

Plant Flow Measurement and Control Handbook 1st Edition

Plant Flow Measurement and Control Handbook is a comprehensive reference source for practicing engineers in the field of instrumentation and controls. It covers many practical topics, such as installation, maintenance and potential issues, giving an overview of available techniques, along with recommendations for application.

PERMISSIBLE LOADING OF GENERATORS AND LARGE .

up to 115 percent load at rated power factor, frequency, and voltage, with the stator and rotor temperatures in excess of normal for these machines. Although this load level does not define the actual temperature rises, it does define the mechanical limit as the value on the machine at rated power factor and 115 percent kVA.

Heat ReCycle solutions | Power plant solutions | Siemens

Siemens' Heat ReCycle solution is determined by a gas turbine power plant with Organic Rankine Cycletechnology (ORC). This combination of proven gas turbine and ORCtechnology for efficient recovery of the waste heat is a response to the market challenges which various regions of the world are facing today.

Emission standards and control of PM from coalfired power ...

and PM for new coalfired power plants with thermal input greater than 50 MW 25 Table 17 German ELVs for NOx, SO 2 and PM for existing coalfired power plants with thermal input greater than 50 MW 26 Table 18 Emission standards for NO 2, SO 2 and PM from Indian coalfired power plants 27 Table 19 Emission standards for SO 2

FAILURE OF DUST SUPPRESSION SYSTEM AT COAL .

Many thermal power plants use coal as their fuel. To handle the coal, each power station is equipped with a coal handling plant. The coal has to be sized, processed, and handled which should be done effectively and efficiently. While working in the coal handling plant the major factor which reduces staff efficiency is the working environment a

Electrical energy.

since the very beginning. For energy generation those included first hydro and traditional thermal power sources such as coal, gas, and oil; later nuclear was added and today renewable energy from the sun, wind and water. At every stage the IEC has led the way in establishing International Standards for transmission, connection and use.

BASIC INSTRUMENTATION MEASURING DEVICES AND .

Instrumentation is the art of measuring the value of some plant parameter, pressure, flow, level or temperature to name a few and supplying a signal that is proportional to the measured parameter. The output signals are standard signal and can then be processed by other equipment to provide indication, alarms or automatic control.

Thermal Insulation Standards

Thermal Insulation Standards. The flow of heat can be delayed by understanding the conductive, convective, and/or radiative behavior of the material in consideration. Such materials include cements, fiber boards, glass blocks, coatings, and blankets, to name a few. These thermal insulation standards help laboratories,...

Weirs and Flumes Flow Measurement InstrumentationTools

Once the liquid level is successfully measured, a computing device is used to translate that level measurement into a suitable flow measurement (and in some cases even integrate that flow measurement with respect to time to arrive at a value for total liquid volume passed through the element, in accordance with the calculus relationship V = ∫ Q dt + C).

Parametric Analysis of Surface Condenser for Thermal .

The thermal power plants are used to generate power. The thermal power plants are designed based on required conditions (like a good quality of steam, pressure and temperature of steam etc.), but actually inlet conditions are not as per the designed conditions.

Latest Posts

- كسارة الحجر والنبات المحجر في الإسكندرية

- طحن المطاحن وتجار التلك الحجر في المملكة العربية السعودية

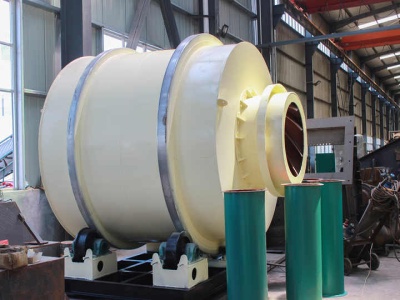

- مطحنة كروية شبه ذاتية المنشأ في الجزائر

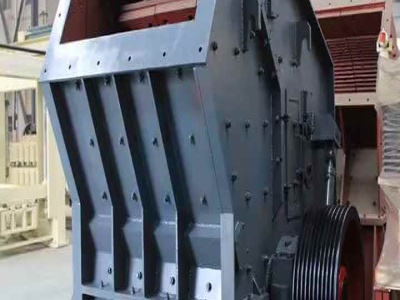

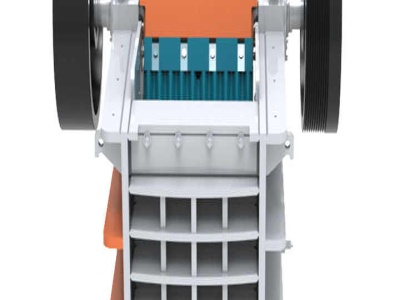

- سوق مصر كسارة فكية صغيرة

- المعادن سحق آلة مصنعين

- قائمة أسعار آلة محطم في مصر

- مصنع زمفارة لتجهيز الذهب

- من الذهب والماسية الآلات في عمان

- معدات مطحنة الذهب المتنقلة 50 tph

- مطحنة شبه منحرفة السرعة المتوسطة

- كسارة الحجارة 50 100 طن متري في الساعة

- كسارة الحجر 200 tph مستعملة للبيع في مصر

- كسارة الفك المحمولة للبيع الجزائر

- آلة التكسير المصنوعة في الولايات المتحدة الأمريكية

- الرمال التفجير آلات سعر

- australian gold ball mill

- ball mill ceramic lined

- water drilling machines from syria

- buy fintec cone crusher

- ball mill for ceramic small grinding machinery grinding

- price of concrete mixer machine in india

- erp ap process flow

- enviromental hazard of limestone mining

- plaza office tower lt

- carbide helical end mill

- fuller traylor gyratory crusher

- sand making machinery feed size mm mm

- nigeria silver factoryri

- grinding stones for in gauteng south africa

- germany copper rolling mill