operation of vibratory screen

operation of vibrating screens pdf

operation maintenance of vibrating screen · Circular vibrating screen machine features: It features reliable structure, powerful exciter, high screening efficiency, low noise, simple maintenance, durable frame, and safe operation. Vibrating Screen For Aggregate,Crushed Limestone Screen.

all operation vibrating screen

linear vibrating screen with vibrating screen all in one machine; all about mining machine; smaill grinding media sold to all over the world; all s cyanidation ball mill; small gold washing machine all in on; za all egories grindingmil; spiral concentrator for iron ores ll; ... all operation vibrating screen;

operation and maintenance instruction vibrating screen

Operation and Maintenance of Vibrating Screen. This article suggests some ways to avoid the problems may occur in operation and maintenance, hope users could solve the concerning problems quickly and efficiently.

Vibratory Screens, Vibratory Screen, Manufacturer ...

Vibratory Screen . Circular vibrating screen or round vibrating screen is a multilayer, highly efficient and new vibration screen machine that moves on a circular motion. It adopts drum eccentric shaft exciter and eccentric block to adjust the vibration amplitude, so that the screening line is long and the screening specifications are more.

Vibratory Screeners Screening, Processing and Size ...

Available for any make or model of circular vibratory screener from 40 to 100 in. (1016 to 2540mm) in diameter Design, Construction and Finish to FDA, 3A, BISSC, EEC and other sanitary standards Design, Construction and Finish to Pharmaceutical Specifications

Vibratory Metal Finishing Equipment | Finishing Systems

Typically the operation employs the use of vibratory finishing compound or agent to facilitate, lubricate, clean and enhance this process. An Advanced Design Vibratory equipment can also be fitted with an internal parts separation apparatus insuring 100% part unloading.

Feeders Screens | LippmannMilwaukee

Lippmann heavyduty vibrating grizzly feeders are ruggedly constructed for proven, dependable, and continuous operation. These builttolast feeders do a superior job of metering the material to the crusher, removing fines from the crushing circuit, and absorbing impact from material of various densities and sizes. LippmannMilwaukee, Inc.

Topsoil Screeners OMH Proscreen

The DeSite SLG108VFRB Vibratory Screener has a 6ft x 10ft screen deck offering more than 55 square feet of screening surface. Priced at 12,600 the 2018 model SLG108VFRB is saving people time and money recycling waste products onsite.

principle of working vibratory screen

Operation And Principle Of Vibrating Screen .Pdf. Vibrating Screen Working Principle The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. Principle Of Operation Of The Vibratory .

Sieving Machine, Circular Vibratory Screen, Vibratory Sieves

The SIVTEK energy separator provides upto 5 levels of gradation for precise particle size distribution in one single operation. The circular vibratory screen is capable to sieve up to 500# with no breakdown. Comes with a high force vibrating motor which serves the purpose with adjustable motor weights .

USA Variable motion vibrating screen Google Patents

In the operation of vibrating screens, it is often desirable to change the ratio of horizontal and vertical components of motion to account for the stickiness of damp materials, the fluidity of dry materials or materials of different densities.

vibratory screens turner

vibratory screens turner vibratory screens turner Vibrating Screen MEKA Crushing Screening. MEKA vibrating screens are designed as a non welded frame with adjustable vibration features to provide efficiency that is both high quality and dependable.

operation of vibrating screens

High frequency vibrating screens are the most important screening machines primarily utilised .... In industry, the screens are operated at a tiled angle up till 40 º. The high frequency (1500 – 7200 rpm) and low amplitude ( – mm)...

Operation of linear vibrating screen

Operation of linear vibrating screen Answer: Operator trainingShould understand the various parts of the equipment structure and simple working principle; before work, should be ready to drive, check the rotation of flexible, non blocking, the screen is intact, spare parts without loosening, bolt fastening.

Circular vs. Linear Vibrating Screen | VibraScreener

Nov 28, 2017· Linear Vibrating Screens. The main difference with a linear vibrating screen is that its motion is linear. It uses a vibrating motor to throw materials in an upward and forward linear motion. These models typically operate with twinvibrating motors that function in a synchronized fashion and move the centrifugal force parallel to the motor access.

Vibratory Feeders: How They Work Why They're Efficient ...

GK Home > GK Blog > Vibratory Feeders: How They Work Why They're Efficient Newton's First Law is the backbone of vibratory feeders. Contingent on the laws of physics an object must first be in motion, to stay in motion.

3 Ways To Prevent Blinding And Pegging On Your MD ...

Jan 15, 2019· Because the McLanahan MD Vibratory Screen has screen decks at progressively steeper angles, we use screen opening sizes larger than the required actual size separation. This by itself reduces the potential for material to cause a pegging situation. However, screens having slotted openings are available to further reduce the potential for pegging.

PQ University Lesson 8 Screening : Pit Quarry

Aug 10, 2015· A vibrating screen can have anywhere from one to four decks, with each deck having a different sized opening, or mesh, for the separation of various particle fractions. Every application is a unique screening challenge, and thus the type of screen media selected is critical for success.

Managing screens and screen maintenance

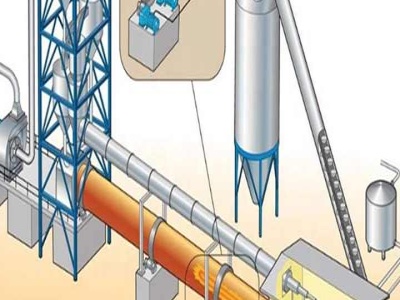

operations, extracted rock is processed by a primary crusher and then passed through screens to produce either the final product or material for further crushing or other processing. However, the use of screens and, in particular, their maintenance and repair, poses a number of

vibrating screens manual operation zaranda vibratory

Home / vibrating screens manual operation zaranda vibratory. Hot. Linear Vibrating Screen Online services. Have Questions? Chat Online. Hot. Grid Type Ball Mill Online services. Have Questions? Chat Online. Hot. Overflow Type Ball Mill Online services. Have Questions? Chat Online. Hot.

Circular Vibrating ScreenVibrating Screen Hongxing ...

Vibrating screen has such features as reliable structure, strong exciting force, high screening efficiency, low vibration noise, long service life, convenient repair, and safe operation, which can screen stone for quarry, and it can also be used for product classification in mineral processing, building materials, electric power, and chemical industry.

Vibrating Screen, Multi Deck High Frequency Screen | H ...

Vibrating Screen Vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate slurry feeds containing solid and crushed ores down to approximately 200μm in size, and are applicable to both perfectly wetted and dried feed.

Latest Posts

- الكسارات الفك المتنقلة سعر المصنع

- سحق الفحم تهتز الشاشة

- كسارة فكية 10 طن في اليوم

- تصفية الصحافة التلقائي لتقليد الذهب والنحاس

- معدات الحصى الرملية هيوستن

- مكينة كسارة في جدة

- محطة كسارة الحجر في هيماشال للبيع

- معدات لانتاج الكاولين

- صور الكرة حجم مطحنة 500

- الثانوية الكرة محطم

- كسارة للبيع في قطر

- مطحنة صغيرة الحجم للبيع

- آلة كسارة السودان في السودان للفحم

- معدات إعادة تدوير الحجر للبيع السودان

- مصمم الحجارة آلة السعر مصر

- monterrey stone crusher

- pepper and beans grinding machine

- mesin pengering pasir sillica

- mining burkina insiders

- iron ore beneficiation plants for sale in australi indian manufacturers of

- gypsum netl doe gov

- business awareness pdf free download in english

- xuanshi crusher for price sale plant stone crusher

- raw materials for mining aluminum kazakhstan

- used process milling machine for sale

- working principle of a jaw crusher

- pea gravel calculator hudson county nj

- calcite powder for plastic making

- japan saw dust vibrat screen mechine

- 01 mpa cement grinding unit erection