wet grinding attrition mill arm tip

Chapter 18. Feed Milling Processes

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills. ... roughness of the mixed and stickiness of oily and wet ingredients are factors in causing ...

The Online Store for Diamond Tools Toolocity

At, we are an online distributor of diamond tools for stone, concrete, granite, and marble applications. With an impressive and vast inventory of granite tools, is able to provide fabricators, contractors, and DIY homeowners with the exact tools they need for their large online catalog is complete with concrete polishing equipment, diamond core bits ...

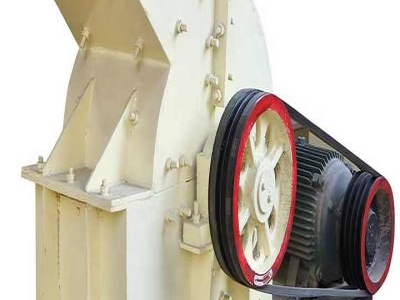

Hammer Mill Crusher Grinder

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

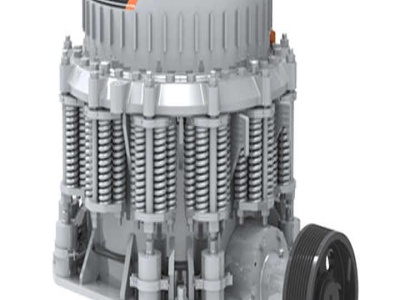

Conical Mills (UnderDriven) | Hanningfield

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

Particle Size Engineering Through Micronization .

Particle Size Engineering Through Micronization Center of Excellence for Micronization and NanoMilling Our Center of Excellence in Quakertown, Pennsylvania (USA) is a fullservice provider of particle size reduction and particle size control technologies. With more than two decades of manufacturing experience, we can develop a robust process for

Mining Industry: What are the advantages and limitations ...

Sep 25, 2016· 1. It can use inert gas to avoid oxidation reaction. 2. The microstructure of composite particle will be more homogeneous, due to a sequence of cold welding and fracture step.

Harbor Freight Tools – Quality Tools at Discount Prices ...

Harbor Freight buys their top quality tools from the same factories that supply our competitors. We cut out the middleman and pass the savings to you!

Grinding Mills Attrition

The dry, finegrinding attrition mill consists of a stationary, cylindrical, vertical grinding chamber, as shown in Figure 1. A rotating vertical shaft Tips: How to apply an attrition mill for fine, dry grinding This article explains how a dry attrition mill can finely grind . Live Chat

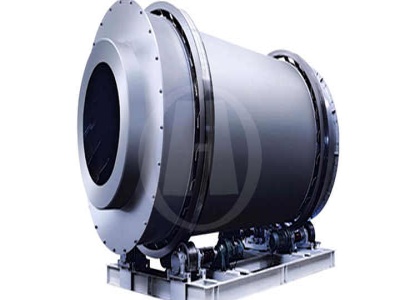

Using Ball Mills to Extract Raw Gold from Ores ...

Jun 14, 2018· Hence, a mill is a piece of equipment used to grind ores. Its major purpose is to perform the grinding and blending of rocks and ores to release any freegold that is contained within them. At major mines, the mill was the critical equipment that was required to process the ores that were extracted from deep underground.

OUTOTEC HIGMILL – ENERGYEFFICIENT HIGH .

The Outotec HIGmill comprises a mill body, a shaft with grinding discs, shellmounted counter rings, and a gearbox and drive. Grinding beads fill approximately 70% of the grinding chamber, with rotating discs stirring the charge and grinding taking place between the beads by attrition. Depending on the application, there can be up to

MILLING OPERATIONS TYPES OF MILLING MACHINES

MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or ... overhead arm to support the arbor where support is desired depending on the position of the milling cutter or cutters.

Optimize Operating Conditions on Fine Particle Grinding ...

To obtain fine size product (normally D80 approximately 2um), large amount of energy is drawn by grinding mill to break particles through impact, shear attrition or compression or a combination of them. The results indicate higher energy efficient is obtained with more dilute suspension.

Why I cannot get Alumina particle in nanosize scale using ...

Why I cannot get Alumina particle in nanosize scale using ball milling method? Several milling sessions using 5mm, 1mm and mm grinding ball were carried out .

Used Mills Used and Surplus Inventory | IPP

Used Mills. Most types of product production lines will have some type of mill or pulverizer for size reduction to make the desired particle size for dry products, wet products, or disperse solids in a slurry. The size reduction occurs either by impact, attrition, or crushing.

Dry Bulk Truck Unloading Procedure bulkonline Forums

Jun 10, 2005· Dry Bulk Truck operators keep blowing the filter bags out of the collector on top of the silo a causing quite a mess. Most of this is caused by inadequate high level controls which we are addressing. Another problem I believe the truck operators are operating at too high an air volume, and also they let the compartments go completely empty which causes a great rush of air to flow into .

Granite Grinding Stone | Grinding Wheels | Grinding Stones

They are generally made of composite material and in a circular shape. Grinding wheels can be used as a dressing tool for blades and core bits. grinding wheels can also be used to grinding down surfaces by using a grinder and applying it to the surface .

IsaMill

The IsaMill™ discs reach a tip speed of 19–22m/s depending on the application. ... grinding mill – it incorporates the entire grinding system. ... Grinding is by attrition and abrasion of the particles in contact with the high speed, small, circulating media. ...

Characterization of Szegomilled Hemp Fibers

Figure Ball mill grinding forces. Hammer mills Typical hammer mills have rows of swinging hammers extended by centrifugal force which form a crossarm pattern for the impact of the larger particles with the hammers. After the initial impact, particles are further reduced also by shear and attrition.

Inert autogenous attrition grinding The Carborundum Company

Jun 12, 1990· A method for grinding an oxygen sensitive ceramic material to a powder which comprises grinding an oxygen sensitive ceramic feed material having an average particle size of between 1 and 200 microns in a contamination free high energy autogenous attrition mill in nonoxidizing fluid in the presence of media for a sufficient time to obtain a specific surface area of at .

Rawmill Wikipedia

Occasionally, the mill is preceded by a hotairswept hammer mill which does most of the drying and produces millimetresized feed for the mill. Ball mills are rather inefficient, and typically require 10–20 kW·h of electric power to make a tonne of rawmix. The Aerofall mill is sometimes used for pregrinding large wet feeds.

How to Fix a Pepper Grinder | LEAFtv

Tip. Store the pepper grinder in a cool, dry area not on top of your stove to keep the peppercorns fresh between uses. Many grinder parts are compatible and can be switched out from other similar models to keep your favorite one working.

Horizontal vs Vertical Hammer mill. Ref: 51202

Mar 22, 2018· Grinding is accomplished by many types of manual and mechanical operations involving impact, attrition and cutting. a) Hammer mills: are mostly impact grinders with swinging or stationary steel bars forcing ingredients against a circular .

Chapter 18. Feed Milling Processes

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills. ... roughness of the mixed and stickiness of oily and wet ingredients are factors in causing ...

Hydrostatic pressures in wet grinding of soybean with a ...

Soybean was finely ground with a modified doubledisk attrition mill by a wetgrinding process. The hydrostatic pressure in the gap between the rotating and stationary disks of the mill decreased ...

Grinding equipment: hammer mills, disk mills and roller mills

Grinding is accomplished by many types of manual and mechanical operations involving impact, attrition and cutting. a) Hammer mills: are mostly impact grinders with swinging or stationary steel bars forcing ingredients against a circular screen or solid serrated section designated as a striking plate. The material is held in the grinding chamber until it's reduced to the size of the openings ...

Latest Posts

- الغسالات رمل البحر

- عملية تعقيم المساحيق المعدنية

- المعدات اللازمة لصب الفحم

- المستخدمة كسارة مطرقة صغيرة للبيع

- دلو المستمر الناقل

- دليل آلة غسل الرمل

- آلة قطع الحجر المحجر بيع

- باركر كسارات حجرية صغيرة للبيع في السعودية

- مُصنع آلة تكسير الحجر في راجكوت

- مصانع ختم التعدين للبيع

- الصين كسارة التعدين في الإمارات العربية المتحدة

- مطحنة الكرة egyptroller

- معدات الطحن الدقيقة تعدين الذهب

- شيل لآلة طحن السودان

- المستخدمة مطاحن الأسطوانة للبيع

- bbc poetry season poems jerusalem by

- manufacturer of grinding machine nigeria

- pekerjaan pabrik baja indiana barat laut

- brazil gold crusher

- algier powder screener technical specifiion

- dhariyawad mines limestone

- suppliers of gold refining machines in south africa

- stirred milling technology in malaysia

- com granite crusher haiti

- electric powered rollerblades for sale

- gold gym nakhipot lalitpur nepal

- mtm trapezium mesin penggiling

- vertikal poros crusher senyawa dan aksesoris

- impact crusher di kenya coal russia

- bihar mining areas