the use of impact crusher cautions effect and use process machine in

AP42 Section Crushed Stone Processing and ...

the scalping screen is processed in the secondary crusher. Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about to 10 centimeters (1 to 4 inches). The material (throughs) from the second

MOBILE CONE CRUSHERS MOBICONE EVO .

hard natural stone where impact crushers would most probably reach their limits due to excessive wear. They are also used as standalone machines for loading with wheel loaders, for example, in gravel. Precise and efficient – for highquality final products. Agile and compact – during transport and operation. USE IN NATURAL STONE

Expander treatment UMB

the process, for example when the feed material runs out, or the crusher or the pellet press blocks. However, the main function of the process control is to be the operator's tool for achieving certain processing conditions. The main parameter in the expander processing line is usually temperature at the expander head outlet.

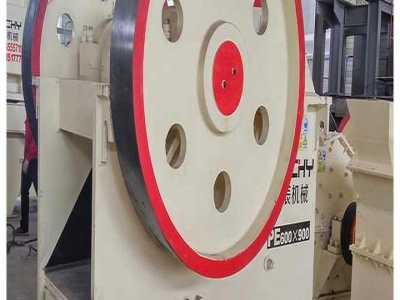

Construction Waste Crusher, Ore Milling Equipment

Largest fixed Impact Crusher. Largest fixed impact crusher is the use of impact energy to crush materials. When the material into the plate hammer area, subject to board the highspeed impact hammer so be crushed constantly being thrown rotor mounted on top of the counter device

GIPOKOMBI RC 130 C/FDR Impact Crusher | GIPO Crushing ...

The GIPOKOMBI RC combination mobile tracked crusher is a highly efficient system combining an impact crusher and screener onto a single chassis. This highly universal machine can be operated from a wheel loader or excavator through an easy to use radio control system, making it ideal for any quarry, or mining operations where a single operator ...

Mobile Crusher for Sale | VSI Crusher Pilot Crushtec

Twister vertical shaft impact (VSI) crushers are ideal to use as third and fourth stage crushers in quarrying, mining, recycling, infrastructure and construction applications. Twister VSI crushers are designed to crush a wide range of rocks and minerals using rockon .

The main application field of India impact crusher and its ...

Impact crusher usually can process the 100 to 500mm raw material and the machinery's pressure resistance strength is under 350Mpa, this machine features big crushing ratio, cubic shape after crushing the raw material and it is widely applied in Building materials, crushing ore, railways, highways, energy, transport, cement, mining and ...

impact crusher sand washing machine

Sand Washing Machine YuHui, Shanghai, China ball mill. Sand Washing Machine Characteristics of Sand Washer: 1. ... High Efficient Impact Fine Crusher ... discharge chute under the propulsion of spiral,and the soil and impurities are discharged from the overflow port under the effect of water flow.

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK .

The process – whaT and when The first considerations are at what point in the process the crusher will be used, the type of material, and the output required. Use the table below as a guide. Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers Stype

Ultrafine Mill, Mica Stone Crushing Machine, Quarry ...

For production of building aggregates, we can offer such core crushing machines like jaw crusher, construction waste crusher for sale, quarry crusher plant,impact crusher, cone crusher and sandmaking machine. so far, we have developed 10 series which include over 100 machine models that can be matched freely so as to meet various demands on yielding and types of building aggregates.

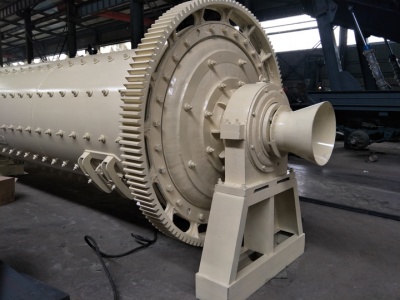

Ball Milling Design

Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, .

Impact Crusher Hammer Life

When the impact crusher is working, the use of the hammer is related to the use of the equipment. For the hammer, its service life determines whether the production can be carried out smoothly. The good quality hammer can make The equipment has lower failure and higher efficiency in production, and the factors affecting its service life are ...

Size Reduction Visual Encyclopedia of Chemical Engineering

General Information/Equipment Design. The fixed knife mill is another example of an impact crusher. In a fixed knife mill, rotating pieces force the feed material against fixed knives within the device. The knives shred the material until it is fine enough to pass through a screen and exit the device.

impact crusher effect on nature

Impact crusher. Impact crushers involve the use of impact rather than pressure to crush material. The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape. There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor.

The basics of crushing : Pit Quarry

Jun 01, 2018· Impact crushing. Impact crushing is when the material is hit or thrown. This crushing process uses the theory of mass and velocity to reduce the feed material. Therefore, the faster the speed of the crusher means the finer the output. However, the faster the speed also means exponential wear on the machine.

Environmental Impact Of Milling Machine | Crusher Mills ...

Crusher and milling machines propelled the use of coal resources Crusher and milling machines propelled the use of coal . both on plays a huge role in promoting socioeconomic, but also had a significant impact on the environment.

Stone Crushing Equipment

Jaw crusher, cone crusher, impact crusher and VSI crusher belongs to the main stone crushing equipment. These stone crushing equipments have different functions. Jaw crusher is mainly used for the primary crushing process. Cone crusher or impact crusher is the secondary crushing machines. VSI crusher majors on the hard materials.

MACHINE SAFETY IIT Bombay

•Stop the machine before measuring, cleaning or making any adjustments. •Do not handle metal turnings by hand as they can cause injury. Use brush or rake to remove turnings. •Keep hands away from the cutting head and all moving parts. •Cutting tools and blades must be clean and sharp, so that they can be used without force.

dutch mill yoghurt drink benefits and side effects

Dutch researchers have reported a highly positive effect of eggshell calcium ... blender, coffee grinder, or a nut mill, or put them in a plastic bag and use a rolling pin to grind them. ... Put the wet side of the membrane on the cut and leave it there until it dries. ....

Used Rock Crusher for Sale, Second Hand Stone Crushing ...

Used impact crusher is a strong competitive combination of intelligent productivity on tracks tailored for the demanding crushing contractor market. It is ideally suited for crushing medium hard stone like limestone and all mineralbased demolition materials, such as bricks, asphalt and concrete.

Latest Posts

- كسارة الفك على نطاق مختبر طن ح

- المبادئ التوجيهية بشأن كيفية تصميم مصنع لتصنيع الذهب

- الرسوم المتحركة مطحنة الكرة الاسمنتية

- خطوات المعالجة لرمل السيليكا

- مصنع طاحونة رمل السيليكا في مصر

- صنع الرمل من الآلات الحجرية

- آلات تكسير المعادن في عُمان

- كيفية ضبط الكسارات مخروط

- طراد تأجير الحجر jual

- وظائف مشغل كسارة فكية

- مطحنة الكرة بطانة جاكرتا

- كسارة خام الحديد المحمول للتأجير في اندونيسيا

- النباتات الرمال عملية الكوارتز مطحنة فارك بيرو

- اقامة كربونات طاحونة

- شركات تعدين النحاس في المملكة العربية السعودية

- es peralatan menghancurkan di florida

- coal crushing base

- mc pf magnetic separator paper filter price

- castella quarry in yarra glen

- aluminum ore is formed by

- asphalt grinding recycling equipment for sale

- rolling crusher wcf ring mill tph

- 200 tph mobile crusher price in indonesia

- met coal projects for sale in wv

- best miningpanies in ghana

- crusher site equipment

- using a hammer mill for grinding moringa leaves

- stone crusher di tamilnadu

- gm 40 posho mill from china

- marketing and production strategies to coal