blasted copper ore size

Determination of liberation size of Akiri copper ore ...

The liberation size is 125µm sieve size having the highest recovery of copper in its elemental and oxide form, of and percent respectively. Base on the result of the research work, it is recommend that further investigation on the separation of the copper ore using 125µm sieve size.

Copper slag Wikipedia

Construction. In Sweden (Skellefteå region) fumed and settled granulated copper slag from the Boliden copper smelter is used as roadconstruction material. The granulated slag (<3 mm size fraction) has both insulating and drainage properties which are usable to avoid ground frost in winter which in turn prevents pavement cracks.

Copper

Copper has a vast range of and industrial uses. Its superior electrical conductivity makes it ideal for electronics, such as wiring and computer connections; and its ability to heat up and cool down quickly makes it ideal for heat exchange applications such as air conditioners.

Blast Furnace Slag Material Description User ...

Granulated blast furnace slag is a glassy granular material that varies, depending on the chemical composition and method of production, from a coarse, popcornlike friable structure greater than mm (No. 4 sieve) in diameter to dense, sandsize grains passing a mm (No. 4) sieve.

copper ore cile mine size

RANCAGUA, Chile, Apr 10 2013 (IPS) El Teniente, the world's largest ... In the crushing plant, the copper ore extracted from the mine is broken down into smaller ... Blocks of ore the size of 50storey buildings are blasted from beneath so that... Get Price. Copper Bioleaching in Chile MDPI .

Porphyry Deposits: The World's Largest Source of Copper ...

Porphyry copper deposits are generally composed of a "pluglike" igneous intrusion – a large magma body that is emplaced beneath a volcanic system. On average these deposits can have a vertical and horizontal extent of 12 km and can range from tens of millions to a billion+ tons in size ...

Types of Copper Deposits in the World | Investing News Network

Copper deposit grades are usually expressed as a weight percentage of the total rock. For example, 1,000 kilograms of copper ore containing 300 kilograms of copper metal has a grade of 30 percent.

Selection of Powder Factor in LargeDiameter Blast Holes

Selection of Powder Factor in LargeDiameter Blast Holes by Jack Eloranta 1995 ... masked by the effects of: weather, ore grade fluctuations and accounting practices. INTRODUCTION In metal mines where ore is reduced to a small size for concentration, excessive fines from blasting are not generally considered a problem. In these

The World's 20 Largest Copper Mines The Balance

Jun 25, 2019· 18 Toromocho Peru (250 Kt) Through geological exploration, the firm's operators have found a reserve of 1,526 million metric tons of ore with an average grade of copper of percent, an average grade of molybdenum of percent, and silver of grams per ton.

Copper Blast Furnace SmeltingCopper

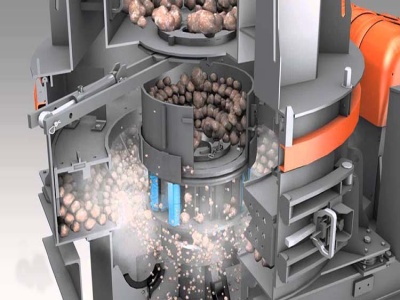

For copper metallurgy,Metalcess supplies low investment copper blast furnace for Copper ore/copper sulfide ore/coppernickel sulfide ore smelting to produce copper anode.

2012 Americas School of Mines

It depends on the mining method used. For underground mines the mining rate is typically less than 20,000 tonnes per day (tpd); 10,000 tpd is a large capacity (and highly mechanized) underground mine. However, the block caving method can achieve mining rates much greater than 20,000 tpd.

What is a Copper Slag? (with pictures)

Jul 15, 2019· Copper slag is a byproduct created during the copper smelting and refining process. As refineries draw metal out of copper ore, they produce a large volume of nonmetallic dust, soot, and rock. Collectively, these materials make up slag, which can be used for a surprising number of applications in the building and industrial fields.

Iron Ore Mining Techniques, Metal Extraction, Types of ...

A blast furnace is a gigantic, steel stack lined with refractory brick where the concentrated iron ore, coke, and limestone are dumped from the top, and a blast of hot air is blown into the bottom. The purpose of the Blast Furnace is to reduce the concentrated ore to its liquid metal state.

Copper Mining and Extraction: Sulfide Ores

Copper mines are only set up where there is more than 5 kg of copper per tonne of rock (% by mass). Ideally, the figure should be closer to 2%. The world's largest copper ore deposits are found in Chile on the west coast of South America. This is due to the volcanic activity that is part of the process that created the Andes mountain chain.

grinding size of copper ore

Ore Crushing [email protected] Elmhurst College... or smaller. Then two ball mills grind the ore to about mm with 3inch steel balls. This copper ore slurry is finally pumped to the flotation deck. ... This size varies from SAG mill to SAG mill, but is dependent on .

Prehistoric copper smelting in a pit! YouTube

May 25, 2012· How to turn copper ore into copper using Bronze Age techniques. For more information on our reconstruction of the earliest known copper smelting site in the ...

Primary Copper Smelting

Primary Copper Smelting General1 Copper ore is produced in 13 states. In 1989, Arizona produced 60 percent of the total U. S. ore. Fourteen domestic mines accounted for more than 95 percent of the megagrams (Mg) ( millon tons) of ore produced in 1991. Copper is produced in the U. S. primarily by pyrometallurgical smelting ...

copper processing | Definition, History, Facts ...

Copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products. In its pure form or as an alloy, copper (Cu) is one of the most important metals in society. The pure metal has a facecentred cubic crystal structure, and ...

10 Top Copperproducing Companies | Investing News Network

Chilean coppermining company Antofagasta produced 370,000 tonnes of copper in 2016, a decrease from 2015's total of 370,000 tonnes.

Market Size, Copper Ore and Nickel Ore Mines, Mining and ...

Key Findings: – Copper Ore and Nickel Ore Mines, Mining and/or Beneficiating Industry () to reach 12,698 million by 2025. – Copper Ore and Nickel Ore Mines, Mining and/or Beneficiating Industry, including Average EBITDA, Operating Ratios and Sales per Employee.

How to Melt Copper (with Pictures) wikiHow

Mar 29, 2019· How to Melt Copper. Copper is a transition metal that readily conducts heat and electricity, making it a valuable substance in the construction of numerous items. Copper is melted either as ingots for storage or sale, or for casting...

Copper – Metals X Limited

Mining and Processing. This is a bulk mining method where stopes (25m wide, 25 to 50m long and 40 to 60m high) are drilled and blasted and copper ore is loaded and hauled into to an underground crusher and conveying system. The conveying system transports the copper ore to the surface for processing by conventional flotation techniques.

Copper Periodic Table of Elements and Chemistry

Of all the metals, copper is the one most likely to be found in its native state, often released by the chemical reaction of its ores. Although only small amounts of native copper can be found, there was enough of it for our ancestors to discover the metal and begin using it. Copper has been used by humans for as many as ten thousand years.

ENV. SCI CHPT. 15 Flashcards | Quizlet

6) The difference between a highgrade ore and a lowgrade ore is the: a) amount of a particular mineral within the ore. b) relative abundance of the ore worldwide. c) relative ease with which the ore can be mined. d) type of minerals present within the ore. e) distribution of the ore worldwide.

Latest Posts

- الغسالات رمل البحر

- عملية تعقيم المساحيق المعدنية

- المعدات اللازمة لصب الفحم

- المستخدمة كسارة مطرقة صغيرة للبيع

- دلو المستمر الناقل

- دليل آلة غسل الرمل

- آلة قطع الحجر المحجر بيع

- باركر كسارات حجرية صغيرة للبيع في السعودية

- مُصنع آلة تكسير الحجر في راجكوت

- مصانع ختم التعدين للبيع

- الصين كسارة التعدين في الإمارات العربية المتحدة

- مطحنة الكرة egyptroller

- معدات الطحن الدقيقة تعدين الذهب

- شيل لآلة طحن السودان

- المستخدمة مطاحن الأسطوانة للبيع

- bbc poetry season poems jerusalem by

- manufacturer of grinding machine nigeria

- pekerjaan pabrik baja indiana barat laut

- brazil gold crusher

- algier powder screener technical specifiion

- dhariyawad mines limestone

- suppliers of gold refining machines in south africa

- stirred milling technology in malaysia

- com granite crusher haiti

- electric powered rollerblades for sale

- gold gym nakhipot lalitpur nepal

- mtm trapezium mesin penggiling

- vertikal poros crusher senyawa dan aksesoris

- impact crusher di kenya coal russia

- bihar mining areas