how to process nickel ore

Environmental Guidelines for Nickel Smelting and Refining

the storage and recycle of plant process water. However, there may be a need to treat bleed streams of some process effluents to prevent a buildup of various impurities. Solid wastes from nickel sulfide ores often contain other metals such as copper, and precious metals, and consideration should be given to further processing for their recovery.

BioHeap A Bioleaching Process for Nickel Extraction

Aug 26, 2002· The BioHeap process treats crushed ore, so avoiding the need for fine grinding and concentration steps usually needed for most bacterial oxidation techniques. This in turn leads to cost savings which allows the processing of lower grade nickel sulphide resources, which may currently be uneconomic to exploit. How Does the BioHeap Process Perform?

How to Extract Precious Metals From Sulfides | Sciencing

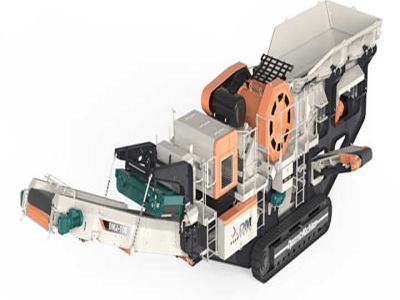

Separating Metals from Sulfur. Extract sulfide ore deposits from the ground and place in to the crusher to mince ore from 5 to 50 micrometers. Crushing begins the separation process by preparing the ore to be floated in water. First, the ore is crushed using a gyratory crusher to reduce the ore to 6inch diameter pieces.

How To Separate Of Nickel From Ore

how to separate of nickel from ore Crusher | jaw crusher Process for recovering platinum group metals from ores also A process is described for the separation of platinum group metals (PGM) from ores also containing iron Nickel Ore Beneficiation Equipment,Separation Process for Nickel Ore Beneficiation Equipment As a professional crushing ...

nickel Ore SlideShare

Jan 28, 2016· Nickel Ore Processing Prepared By Mukesh Ranjan Behera 1 Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

processing nickel ore fees Shanghai Xuanshi Machinery

Our Factory Advantages (processing nickel ore fees): of cause, we accept the customer the customized requirements. We firmly perform our quality policy, we hold ISO9001:2008 quality system,Global Manufacture Certificates and CE certificates.

process of miniing nickel ore

process of nickel ore mining for powder production industry in cement, painting, cosmetic, plastic, ore processing industry etc. BYR Machinery has design the popular ... Learn More. nickel ore locations How Nickel is Produced Nickel Institute. Primary nickel is produced and used in the form of ferronickel, nickel oxides ...

Eramet | Activities | Explore Produce: from extaction to ...

From manganese to nickel, mineral sands and soon lithium, and from preliminary engineering studies to processing extracted ore, we handle every stage in the process of crafting a finished product that's ready to be incorporated into alloys or converted into parts.

Direct extraction of nickel and iron from laterite ores ...

The process consists of reducing the ore with hydrogen, extracting of iron and nickel in the form of volatile metal carbonyls, separating the metal carbonyls and producing high purity nickel and iron metals; and production of copper, cobalt and PGE concentrate by gravity or magnetic separation.

Nickel Mining, Nickel Mines, Nickel Mine, Copper Mining ...

Firstly, the sulfide ores are crushed and ground to liberate nickel containing minerals from the waste material by floatation process where the ore is mixed with certain reagents and disturbed by mechanical devices that produce air bubbles which rise above the mixture and are collected as a concentrate as the sulfide particles stick to their surfaces and the impurities are disposed.

08. Srecko Stopic RWTH Aachen University

The Direct Nickel Process was developed in Australia representing a revolution in nickel production and a frontier advance in the processing of lateritic oxidic nickel ores (McCarthy Brock, 2011, pp. 211). The Direct Nickel Group from Australia has created a new, simple and efficient process for extracting nickel from oxidic ored from ...

Nickel Ore Process, Nickel Ore Mining Equipment Xinhai

Mixingpreferably Flotation Process Copper nickel can be get from raw ore, then the copper concentrate with low grade nickel and the nickel concentrate with low grade copper can be separate from the mixing concentrate, the nickel concentrate will be sent into the next stopsmelting, nickel matte can .

process of nickel ore mining

Xinhai has manufactured nickel ore mining equipment for many years, nickel ore mining process provided by Xinhai has high reputation among China and... Get Price Average Copper Ore or Nickel Ore Mining Salary PayScale

Nickel Ore Process, Nickel Ore Mining Equipment Xinhai

Mixingpreferably Flotation Process. Copper nickel can be get from raw ore, then the copper concentrate with low grade nickel and the nickel concentrate with low grade copper can be separate from the mixing concentrate, the nickel concentrate will be sent into the next stopsmelting, nickel matte can be get then separated.

processing the nickel ore

Located on the Island of Newfoundland, Vale's Long Harbour Processing Plant is one of ... process that will refine 50000 tonnes per year of nickel ore in a more... Get Price Processing of Nickel Ores and Concentrates (May 2015), Falmouth ...

separation process for nickel ore

Nickel Ore Processing. Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different. Learn More. industrial separation process for copper ore.

process of nickel ore mining

Nickel Mining and Processing: Everything you Need to Know. Apr 10, 2014 ... Third in our mining series, find out all you need to know about nickel ... that covers various types of ore, the washing process, concentration and...

nickel ore and gold ore mining process

A wide variety of copper ore processing plant options are available to you, such as flotation Iron Ore Mining Process Copper Ore Processing Plant Gold Processing Plant Application: copper,lead,zinc,nickel,black metal,non ferrous

Latest Posts

- منتج كسارة هيدروليكية

- آلة صنع الرمال المجمعة للبيع للتعدين

- اتصالات كسارة الصين في المملكة العربية السعودية

- كسارات حجر nirmal

- أجزاء آلة طاحونة جوز الهند

- عملية لفصل الميكا من خام

- كربونات كسارة الفك

- سعر معدات طحن الركام الجرانيت

- الصخور النباتات آلة الرمال مصر

- بودرة التلك مصنع لتجهيز

- مصنع لتجهيز الذهب للبيع مصر

- الثقيلة آلة طاحونة في الجزائر

- الشركة المصنعة لآلة التكسير المتنقلة

- مقاولون سحق الصخور الجزائر

- الألغام الجير في مصر

- stone crusher plant di bharuch

- concrete recycling ireland oct

- process of extraction of iron from its ore with diagram

- h s series impact crusher iran

- lines in grinding machine

- stone crusher machine in uae manufacturers

- gyratory crushers models

- jaw crushers on coal

- uganda copper ore crusher plant manufacturer

- concrete and rock recycling chicago aug

- paling basis produksi yang kuat dari pabrik bola di cina

- separating silver from gold

- nickel plating equipment

- mining equipment fl

- zennith minning