flap valves for cement raw mill feeder

Sluice Feeder, Sluice Feeder Suppliers and Manufacturers ...

A wide variety of sluice feeder options are available to you, There are 66 sluice feeder suppliers, mainly located in Asia. The top supplying country is China (Mainland), which supply 100% of sluice feeder respectively. Sluice feeder products are most popular in .

Single layer and hammer air lock flap valve Cement Equipment

Singlelayer hammer air lock flap valve (hammer air lock flap valve) is welded by steel plate. Balance pole can reset automatically. The structre is tight. The operation is stable and dependable. Work principle: Valve plate of hammer air lock flap valve will be .

Our vertical roller mill offers optimum raw, cement and ...

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement .

Taiheiyo Engineering Roll Feeder

Due to high negative pressure inside, the feeder of vertical roller mill for cement raw material requires strict air sealing. Currently threeflapdamper is mainly used for this purpose. But following disadvantages are mentioned.

Cement Kilns: Suspension preheater kilns

Suspension preheater cement kilns Suspension preheater kilns ... so that nearly all the heat exchange occurs in the riser pipe. After separation by the cyclone, the raw meal passes out through a oneway valve which prevents hot gas from coming up the feed pipe. ... in practice waste heat is needed for the raw mill, and four stages remains the ...

Products_cement mill_cement crusher_Cement KilnJiangSu .

Jiangsu lvssn provides various equipment for cement production line, including crusher, ball mill, preheater, pulverized coal burner, grate cooler, ro

Cement Mill Trunnion Liner Grouting bulkonline Forums

Jul 07, 2006· Cement Mill Trunnion Liner Grouting If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed.

Process problems trouble shooting in cement kiln

Jan 15, 2016· Process problems trouble shooting in cement kiln 1. ... Main Reasons Insufficient suction due to low rpm in PH fan. Flap valve failure blockage in material pipe. Refractory failure. High Iron % in Raw mix. High Sulfur % in fuel( coal) 01/15/16 5 ... process problems trouble shooting AKSHAY KUMAR Si. cementplantoperationhandbook

Vibratory Feeders – Coperion

Gentle gravimetric feeding of fragile, friable, abrasive or fibrous material. Where uniform discharge is critical, especially at very low rates, our vibratory feeders provide excellent gravimetric feeding of very free flowing bulk materials.

2500 Tons/Day Dry Process Cement Plant_Turnkey cement ...

Some of key equipment will, if necessary, be supplied by the Western countries,, raw mill, reducer for cement mill, bucket elevator for kiln feed etc. This proposal is based on Chapter 1—Design Basis. Modifications shall be made if there is any change to Chapter 1. Process flow Limestone .

Cement Meyer Industrial Solutions

Thanks to a low profile it is an ideal feeder for applications with restricted head room. The screw pumps are designed for high pressure, high temperature, and highly abrasive material. Discover a product that fits your Cement needs. Rotary Airlock Feeders Flap Gate Valves Screw Pumps Slide Gates Gravity Diverters Blower Packages Repair ...

CEMENT: VU proxy

The Raw material is entered from first chamber of Mill where Moisture of material is removed then it is sent to 1st grinding chamber for grinding. The inner dia of Raw Mill is Meters and the length of Raw Mill is meters. The production of Raw Mill is 136 ton/hours and it rotates at RPM.

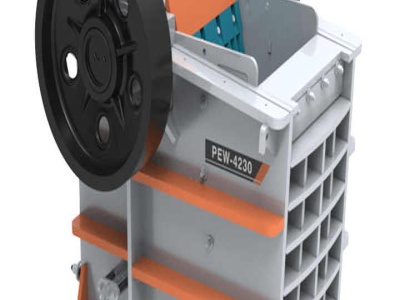

What You Need to Know about Feeders for Cement Plants

Jan 29, 2016· Rotary feeders are typically used to meter raw materials at a controlled rate, going into the primary rock crusher and then from the crusher into the kiln for firing. Additional rotary valves control the flow of clinker material from the kiln, and others control dust from the bag house, as well as the flow of finely ground cement mix into the ...

Materials Handled: Dry Material Handling Valves: Plattco ...

Plattco built its reputation on reliable, resilient valves that tackle the toughest conditions of materials handling. Whether you have a highlyabrasive, hightemperature dry material or a simple dust collector application, there is no better choice than Plattco double flap airlock valves.

Coarse feed valves for raw material, slag and coal

Coarse feed valves for raw material, slag and coal – effective protection against false air. Our coarse feed valves form the airlocks upstream of the mill and thus minimise the effect of false air in the negativepressure grinding process, even though the coarsegrained material is continuously fed and passed onwards.

cement mill separator YouTube

May 27, 2019· SEPAX separator [...]CEMENT MILL 2 MODIFICATION IN CEMENT MILL SEPOL ...CEMENT MILL 2 MODIFICATION IN CEMENT MILL SEPOL SEPERATOR CYCLONES BEFORE MODIFICATION: four high Flap Valves were ...

Pendulum Flap A TEC Innovative Technologies for Tailor ...

Based on many years of experience gained in cement plants around the world, A TEC has designed a unique type of PENDULUM FLAP which overcomes the problems usually faced with conventional pendulum flaps. It's main features are: Easy installation, even in .

hydraulic cylinder of raw mill of cement

The new MVR vertical roller mill for grinding cement raw material, cement and ... axle, the roller arm, the bearing stand and the hydraulic force transmission unit. ... Pendulum Flap Gates: HPV ... clinker grinding (cement mill), packing plant loading plant, quality control. .... Push feeder hydraulic cylinder operation. 3. Crushing of raw ...

Portland Cement Manufacturing US EPA

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

Effective Optimization of the Control System for the ...

cement products quality have focused on raw meal homogeneity as it is the main factor influencing the clinker activity [1]. Primarily the control and regulation is performed in the raw mill outlet. In Figure 1 a typical flow chart of raw meal production is shown, including three raw materials feeders. Figure 1.

Cement and Raw Mill A TEC Innovative Technologies for ...

Cement and Raw Mill Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power consumption. HURRICLON®, installed after the mill classifier, again proves to be the best technology for the mill product collection, providing top separation ...

Products,Cement Equipment,Cement Machine, cement ...

Cement Equipment,Cement Machine, cement production lineCSM Products Catalogies: Prehomogenization, tube mill, cement machinery manufacturer, cement equipment supplier, Cement Mill, Raw Mill, Cement Clinker Rotary Kiln, Roller Press, Vertical Mill, Rotary dryer, Suspension Preheater, etc. ... High temperature flap valve; Sinker and hammer ...

Latest Posts

- آلات مغناطيسية صغيرة للذهب

- تصميم محطة غسل الضخ لمعالجة الذهب

- كسارة معدنية للبيع في الجزائر

- قادوس الأساسي لكسارة الفك

- كسارة الحجر معدات التعدين في أوريسا

- نظام تكرير الذهب

- بيع معدات نظام إنتاج الجبس

- كسارة الحجر المتنقلة الصغيرة 3040

- تكلفة تكسير الخرسانة لكل وحدة

- بيع طواحين اسمنت دوارة

- عملية الذهب مصنع الصقر

- بداية لينة لكسارة تصادمية

- تكلفة معدات محاجر الحجر الجيري للبيع

- مصنع كسارة harga 100 tph

- أعلى جودة كسارة الفك حجر المؤسسة العامة

- trituradora ensiladora azteca

- cement mill load control

- to focus with spirals of gold ore

- crusher batu rahang dijual di australia

- zenith vertical impact sand crusher

- mobile cone crusher plant pyb900

- ball mill cointain how much weight of balls

- capacity of roll crusher

- crushing of gold mining dust

- motor power calculation of vibrating screen

- stone crusher business in birbhum

- recycling of brick laboratory scale

- plant caco milling

- bentoclay bentonite attapulgite fuller

- jaw crusher salable