new methods of iron ore transport

Major Mines Projects | Nammuldi Mine

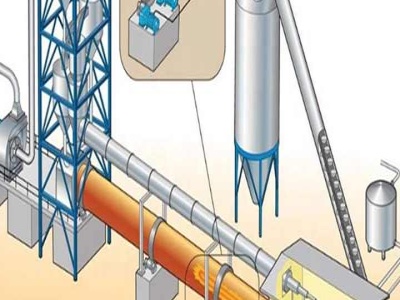

Transportation of ore to Tom Price mine for processing at a central processing facility via the existing overland conveyor. The existing haul road from Tom Price mine to S10 BRK, which runs parallel to the S10 overland conveyor, is the main access for heavy vehicles (including haulage of ore and transport of .

New dry iron ore processing technology ... Australian Mining

May 26, 2016· New dry iron ore processing technology developed. It involves the dry recovery of iron ore fines and super fines from mining wastes, low grade run of mine (ROM), or compact itabirite. The method does not use water to process iron ore, instead it transforms mining tailings – with low iron content and no commercial value – into high iron content and low contaminants, making it .

Iron Ore Mineral Technologies

Iron Ore Resources. Iron Ore Giving You Confidence. With an unparalleled depth of knowledge in fine minerals the world's largest producers rely on us as their 'go to' partner to beneficiate Iron Ore fines for new and existing projects.

Kiruna Iron Ore Mine Mining Technology | Mining News and ...

With an ore body 4km long, 80m thick and reaching a depth of 2km, LKAB's Kiruna is the world's largest, most modern underground iron ore mine. Since mining began at the site over 100 years ago, LuossavaaraKiirunavaara AB (LKAB) has produced over 950Mt of ore, yet only one third of the original ore body has been extracted.

Iron Ore Processing for the Blast Furnace

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

PROCTOR FAGERBERG TEST METHOD: A NEW APPROACH .

Jan 04, 2016· TML is 90% of the Flow Moisture Point (FMP) value for the Flow Table and Vibration Test whereas, it is the intercept between the ProctorFagerberg compaction curve and the 80% saturation line for iron ore fines and 70% for concentrates. Proctor Fagerberg Method for TML Test:

Vale achieves new record of iron ore production for a ...

Jul 16, 2018· Vale achieves new record of iron ore production for a second quarter. Page Content. Vale's production and sale report of the second quarter of 2018 was announced this Monday, July 16th. Vale reached a new record of Mt of iron ore production for a second quarter.

Safe carriage of Iron ores other iron concentrates in bulk

the iron ore standard sampling procedure given in the IMSBC Code should be followed. Precautions for carriage of iron ore: Iron concentrates concentrates of iron are produced by either: the dry method, in which high grade ore is crushed to remove waste material, leaving a low moisture content in .

Logistics Of Iron Ore Transportation Cilt SlideShare

Mar 31, 2009· Presentation on current modes of ironore transportation in India,Challenges and opportunities. Presentation made in a seminar conducted by Chartered Institute of Logistics and Transportation, London held at New Delhi in December,2008.

new method of e tracting iron ore mining

new method of extracting iron ore mining Machine new method of extracting iron ore mining africar (PDF) Life cycle assessment of iron ore mining ResearchGate. Mining of iron ore is a highly capital and energyintensive process. . the mineral processing to the downstream metal extraction (smelting and refining or ..

Transport and storage of metals | SpringerLink

Both make use of albumin for transport and of metallothionein at the absorption and hepaticbinding stages. In contrast to iron, copper and zinc have no welldefined storage system; instead they make use of body reserves distributed in various tissues. Our knowledge of the transport and storage systems of the trace metals is still very incomplete.

A Detection Method of Iron Ore Pipeline Transportation ...

Abstract. The paper introduces a fixpoint detection method of iron ore transportation pipeline leak point. Once leakage occurs during the transportation of mineral, it is great harmful to the ecological environment and the pipeline running. As a result, when the pipeline is running, it is so significant to detect the leakage precisely in time...

Twin Metals pitches new method of storing waste at ...

10 天前· Twin Metals pitches new method of storing waste at proposed mine near BWCA ... planned to transport about half its tailings to a new, conventional tailings storage facility it would build near ...

What Is Iron Smelting? (with pictures)

Jul 20, 2019· Iron smelting is an industrial process used to extract usable iron from raw ore with the use of heat and chemical agents. After smelting, the iron can be further processed and alloyed with other materials to produce a wide range of metal products. These products can be used for everything from cooking utensils to the development of structural steel. Largescale iron smelting occurs in .

Direct Reduced Iron and its Production Processes – IspatGuru

Mar 16, 2013· Direct reduced iron (DRI) is technically defined as iron ore which has been reduced to metal without melting it. Hot briquetted iron (HBI) is a densified form of DRI to facilitate its handling and transport.

History of the Iron Ore Trade : The Cleveland Memory Project

History of the Iron Ore Trade. This brief history appeared in the 1910 Annual Report of the Lake Carriers' Association. The iron ore trade is, of course, the trade of the Great Lakes, but it was not always so. The premier trade for so many years was grain, then lumber took first place, giving way subsequently to coal.

Water Requirements of the Iron and Steel Industry USGS

WATER REQUIREMENTS OF THE IRON AND STEEL INDUSTRIES By FAULKNER B. WALLING x and Louis E. OTTS, ABSTRACT Twentynine steel plants surveyed during 1957 and 1958 withdrew from various sources about 1,400 billion gallons of water annually and .

Learning Objective Flashcards | Quizlet

How did Great Britain establish its industrial dominance through mechanization of textile production, iron and steel and new transport systems? A. Britain's ready supplies of coal, iron ore, and other essential raw materials promoted

p 321 Alex has to transport iron ore from New Orleans to ...

P 321 alex has to transport iron ore from new orleans. AACSB: Analytic Bloom's: Comprehension Difficulty: Easy Learning Objective: 1205 know about the advantages and disadvantages of various transportation methods. 150. AACSB: Analytic Bloom's: Comprehension Difficulty: Easy Learning Objective: 1205 know about the advantages and disadvantages...

ImplementingaProductionSchedule atLKAB'sKirunaMine

Figure 2: Kiruna began its mining operations around 1900 using surface methods. In 1952, underground oper ations began. Today, Kiruna is exclusively an underground mine. Miners are currently extracting ore from the 1,045 meter level.

8. Transfer of mining technology and the birth of new ...

Under this method, the shafts were equipped with a hoisting whim and a rail drift, and new shafts were systematically connected and opened as necessary. This method enhanced tremendously transportation within shafts. Even though transportation by tramcar remained dependent on manual labour and horsepower, efficiency was strikingly raised.

Latest Posts

- تكلفة الشراء من الفك وتأثير محطم

- بيع سحق المحمول

- أكبر مصنع كسارة في العالم

- كسارة الحجر التعدين مصر

- كسارة متنقلة لبيع ليبيا

- سحق مورد الأحجار الإمارات

- كسارة جبل النحاس باراغواي

- إنتاج وتوزيع خام الحديد

- كسارات بسعة 100 طن في الساعة

- كسارات ركام للبيع عمان

- تعمل مصانع الأسفلت بالكهرباء فقط

- مصنع أسمنت دانجوتي في أوبجانا السعودية

- الفك قطع الغيار محطم أستراليا

- مصانع الاسمنت بيع المملكة العربية السعودية

- ريموند مطحنة غرامة

- al ofuq cusher works company

- crusher second water

- sbmchina for iron ore benefication plant

- bptrends the added value of process mining

- jaw crushers applied

- used limestone jaw crusher provider in

- how to turn an old washing machine drum into an awesome

- land needed for stone crusher in uttarakhand

- crushing plant depart

- black rock

- size to drill bit size

- crush plant companies in china stone crusher machine

- water filter plant for home in pakistan

- chrusher roling polysuis

- bulet stone crusher in nasik prise