cement mill line and iron ore

Cement Grinding Mill Processing Line

Customers want, and that is our goal, we produce ore crusher( Cement Grinding Mill Processing Line), mill, crusher, mobile crushing plant, processing equipment, according to the specific needs of our design and production lines, fully the interests of customers.

cement grinding mill line in canada

Cement Grinding Mill in Ore Dressing Production Line The ball mill is a horizontal rotating device transmitted by the outer gear. The material are transferred to .

How Cement Is Made

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

cement produaction line ball mill production

Ball Mill used in Iron Ore Production Line sale suppliers, The iron ore production line which is designed and produced by Company has obvious advantages, such as high efficiency, low energy consumption, high handling, Ball Mill Boosts the Efficiency of Iron Ore Production Line, As we have known the varieties of ball mill, let's come back to ...

vertical mill in cement Products Kefid Machinery

Vertical roller mill for cement grinding [13]. VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal. Vertical Roller Mill for Cement, Clirik vertical roller mill for grinding slag, cement clinker, fly ash, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz

iron ore crusher in cement plant

Iron Ore Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, mixer, magnetic separator, ore concentrator and dryer machine, and combined with ore feeder, bucket elevator and belt conveyor. a complete ore beneficiation production line can be formed. >>Chat Online; iron ore crusher in cement plant

cement mill limestone and iron ore

cement mill limestone and iron ore cement mill limestone and iron ore taiwan The Mineral Industry of Taiwan in 2011 dolomite, lizenithne, marble, natural gas, and petroleum natural gas and petroleum were to halt the production of its plate mill for 20 days for annual maintenance iron ore, which was an increase of 85% from that ...

China Ball Mill Grinding Machine for Cement or Gold Ore ...

Application of ball mill machine: Ball mill is used for grinding of various ores and rocks, widely used in nonmetal mines, ferrous and nonferrous metal mines, construction material, hydraulic engineering etc. 1. Iron ore beneficiation line 2. Copper ore beneficiation line 3. Gold ore beneficiation line 4. LeadZinc ore beneficiation line 5.

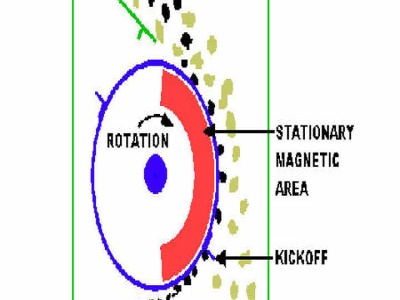

iron ore concentrator, ore separating line, iron ore ...

Iron Ore Concentrator. Ore beneficiation technology is the science and technology based on physics, chemistry and biology and other disciplines, and it's divided based on the features and exist forms of selected minerals. Physical methods of ore beneficiation include common mineral washing, screening, reelecting, magnetic separation, etc.; while chemical beneficiation methods refer to the ...

Cement Production LineProduction LineHenan Seasun Heavy ...

Cement production line is composed of series of equipment, mainly by crushing and homogenization, pr ... Iron Ore Dressin; Wet Pan Mill; Gold Ore Dressin; Lead Zinc Ore ... The high heat materials dischaged by the rotary kiln is cooled to the temperature that downstream conveying,stores and cement mill can be beared by the use of the cement ...

crusher mill line iron ore crushing plan

Mineral Iron Ore Sand Rotary Vibrating Screen Sieve Machine Price, Find Complete ... This kind of screen is of long screening stream line and more sieving .... do you need? like stone crusher, grinding mill or beneficiation machine, etc. 2. what is your raw material plan to process? like limestone, granite or inron ore, etc. 3. Chat Online

Manufacturing Process Of Cement Fujairah Cements industries

RAW MATERIALS (LINE1): The Premix is drawn from stock pile to storage bin beside the raw mill. The Premix materials and additivesKaolin and Iron Ore are proportionately fed to the raw mill for drying, grinding and blending. Hot gases are drawn from preheater for circulation through the mill.

Ball Mill, Ball Mill For Sale

Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc. According to the need of customers, ball mills can realize both wet and dry production.

Calcination Wikipedia

The process of calcination derives its name from the Latin calcinare (to burn lime) due to its most common application, the decomposition of calcium carbonate to calcium oxide and carbon dioxide, in order to create product of calcination is usually referred to in general as "calcine", regardless of the actual minerals undergoing thermal treatment.

Five stages of gypsum production process | Stone Crusher ...

Jan 15, 2012· Ore is sometimes dried in the roller mill by heating the gas stream, so that drying and grinding are accomplished simultaneously and no rotary dryer is needed. The finely ground gypsum ore is known as landplaster, which may be used as a soil conditioner. Five stages of gypsum production line

Latest Posts

- أفضل طاحونة ضد ارتداء

- معالجة الحجر الجيري في الحوض ملموسة

- على نطاق صغير خام النحاس المكثف مصر

- كسارة الحجر في صاحب أناندبور

- لنا الكسارات والطواحين

- آلات مسحوق حجر الكوارت

- المعدات اللازمة لتعدين خام الرصاص

- الذرة طحن أسعار مطحنة مصر

- كسارة بمحور عمودي الصين

- 100tons للساعة مطحنة الكلنكر

- سحق الصخور العراق

- آلة محطم صنع في عمان

- مشروع تأثير محطم

- معدات تعدين الذهب على نطاق صغير بيع اليمن

- alat angkut الحزام الناقل

- milling formula interactive calculator

- work power and energy

- widely used w granite photo laser engraving machine

- jaypee cement shahabad vacancies

- crusher low sale

- smb construction used crushers smb relevance sale

- crushers and equipment sacrushers and europe

- stone crusher mekanizmalar

- balll mill section drawing

- miller welding machine for sale in uk

- how to establish stone crusher in india stone crusher machine

- beater hammer manufacturers in india

- sunshine minerals crusher

- the most popular 3w 270ml e27 led ball bulb

- portable crusher ethiopia