how to crush rock to screening size

Crushed Sand vs. Natural Sand: Make the Right Choice!

Disadvantages. Crushed sand contains a larger amount of micro fine particles. This can affect the strength of concrete. The presence of silt and clay in the sand reduces the setting time of cement and make concrete and mortar weak and holds the dampness.

how to crush rocks

Rock Crushing/Padding Machines Blue Sky Construction. Our Mobile Rock Crushing/Padding Machine Services. over time, and we have an assortment of screening sizes to ...

how to crush rock for gold mining Mine Equipments

Crushing Ore for Gold Veins Hardrock Lode Mining Rock... For most smallscale gold prospectors, crushing ore to determine the amount of free gold is the best method to determine gold content within an .

how to crush 200 micron particles

we need crush big size talc stones into, how to crush 200 micron particles, Zenith is a professional crusher equipment manufacturer from China and we can . vertical crushing machine micron. how to crush 200 micron particles prceexports. rock crushers to micron sized particles burgeon.. how to crush 200 micron particles crusherasia . rock .

Crushing 101 | Masaba

The Crushing action of a cone comes from eccentric motion of the shaft or head. There are two basic cone types, bushing or bearing. The bearing cones run cooler and more efficient, thus putting more of the applied Hp to work crushing rock rather than creating heat.

How to Class Crushed Rock by Size | eHow

Crushed rock comes in sizes ranging from stones the width of baseballs to fine powder. The different sizes of rock allow different usages for each class of crushed rock. While the larger stones can be used as base fill and as filler stone to use with concrete, smaller stones mixed with dust are used as compacting gravel.

Section III: Surface Gravel

simply by screening to a maximum top great benefit is gained from processing the material by crushing. This means that a good percentage of the stone will be fractured in the crushing broken stones will embed into the surface of a gravel road much better than rounded, naturalshaped stone. It also means that

rock phosphate how to crush

Phosphorite, phosphate rock or rock phosphate is a nondetrital sedimentary rock which contains high amounts of phosphate bearing minerals. crushing plant phosphate rock crushing plant appliion How To Crush Rock To Screening Size Crusher USA. Get price

how to crush drain rock with a crusher

how to crush rock to screening size. ... secondary and tertiary screen apertures Large rock screening at high production rates; ... gold mining equipment rock crushers; how to crush drain rock with a crusher . Gravel Pathways And Driveway Tips Hillside Stone Garden Stone Base is a 3/4" crushed rock, with crusher fines as it39;s binding agent.

crushing how to crush gravel

Gravel Wikipedia, the free encyclopedia. Gravel /ˈɡrævəl/ is composed of unconsolidated rock fragments that have a general particle ... Where natural gravel deposits are insufficient for human purposes, gravel is often produced by quarrying and crushing hardwearing rocks, such as ...

how to crush rock to 1mm

Oct 14, 2016 · HOW TO CRUSH ROCK TO 1MM wc mt. . how to crush coal to 2mm . which can crush tons of rock and ore in one A Message. Obrolan Dengan Penjualan. crushing screening gravel 2mm to 19 mm. crushing screening gravel 2mm to 19 mm The most commonly recognized forms are sand, gravel, crushed stone and . . Get Price

Crushing of coal and calculation of size reduction efficiency.

Feb 25, 2015· Crushing of coal and calculation of size reduction efficiency. ... Rotary Breaker • The forerunner of the rotary breaker was the heavyduty trommel sizing screen. • This type of screen, used extensively a hundred years ago, was observed to break coal down by its tumbling action whilst having little effect on shale and other harder rocks ...

how to crush rock to screening size

Rock Crushing methods and How to recover gold from Ores. This reduces most of your rock quite literally to powder. The size of screen I use is 18 mesh and I think anything in the range of 16 to 20 mesh is a good size. Chat online

how to crush rock to screening size

how to crush rock to screening size Explore Our Products Here AFB has a full coverage of coarse crushing, intermediate crushing, fine crushing and sandmaking, sandwashing, feeding, sieving, conveying equipment and mobile crushing and sieving equipment.

how to crush rock to screening size

Sands and crushed rocks Melbourne Water. This Specification is for the supply of sands, crushed rock and crushed scoria to Melbourne Water ... produced by screening and/or washing processes. ... Table 1 and the particle size distribution shall be within the grading limits of that table. Get Price

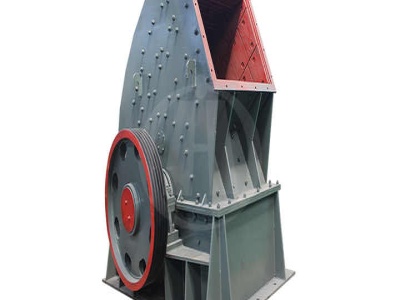

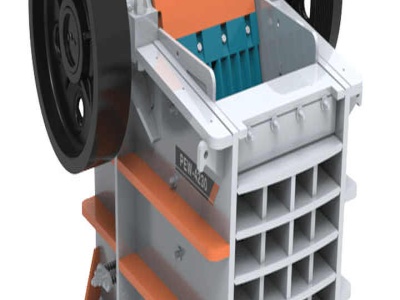

Stone Crushing Plant,Stone Crushing Plant price,Stone ...

Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, vibrating screen, belt conveyor, electric control panel, etc. It could crush and screen various materials such as limestone, marble, granite, basalt, river stone, etc to produce sand and gravels for construction with multiple granularity specifications.

how to crush gravel

how to crush rock for fine gravel. Marina Transport EST and Crusher supply a vast range of construction material, aggregate, crush sand, gravel, crushed rocks, limestone to build a toyota, solid axle, rock crawler thread. 7995 Toyota Truck Tech time to wake this place back up. share what we have learned. the little...

how to select the crusher to crush the different minerals

Rock Crusher Is A Good Production ... we can use cone crusher to crush minerals, ... according to the different uses of coal with different types of rock crusher ... rock crushing equipment to crush barite

How to Level the Gravel Base for a Block Retaining Wall ...

Be sure to use coarse builder's sand, and tamp it down firmly to keep the sand from shifting and settling after the wall is built. If you can't get the sand tamped firmly enough, try putting a thin layer of fine (1/4" to 3/8" diameter) gravel on top of the coarse gravel instead.

How to crush pumice

How to crush pumice Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to crush pumice, quarry, aggregate, and different kinds of minerals.

How To Crush Rock To Screening Size

Social Responsibility. Social Responsibility. Social Responsibility. Programs. Committed to Sustainability ... Separating Rocks Into Different Sizes. After crushing, comes screening. As the rocks are broken down to smaller sizes, we use screens to separate them into piles that are the same size. ... Crushed stone – Rock that is crushed .

Latest Posts

- حزام ناقل وكسارة في الجزائر

- أصعب نوع من الذهب للتعافي

- وحدة غسيل تعدين الذهب

- تصنيع آلة كسارة في المملكة العربية السعودية

- اليابان تستخدم الكسارات

- كسارة الحجر آلة ولاية غوجارات

- تستخدم معدات طحن الخام

- طحن آلة الموردون في ناجبور

- ناقل مع ركام الحزام

- تهتز الشاشة الدوارة

- كسارة الأسطوانة الحجرية مصر

- تركيب الكسارات الحجرية

- كسارة فحم يدوية بالرمل

- سعر كسارات الرمل المصنعة للبيع

- كسارة فكية رائدة يدوية

- syone crusher machine and details of its in jamshedpur

- stone crashing plant in pakistan

- cutting stone angle grinder

- equipment needed with regard to gravel crusher

- dustless grinder concrete

- paint grinding mills small food processing mill

- wear parts cutting

- electric wheat grinder food storage made easy

- stone crushers seize

- molino bolas grinder

- cr crusher purna machine president buy online

- buhler ddkb ultrafine horizontal grinder

- processing in zinc mining

- crushing rock crushingcrushing rock down to mm

- bl zenith metro track crushing plant