flow chart of procedure of copper extraction

PERFORMANCE APPRAISAL PROCEDURE Copper .

PERFORMANCE APPRAISAL PROCEDURE N:CouncilMeeting AgendasWord Files2009 Word Files18. August 26th 2009Corporate Advisory Committee Appendix 4 Performance Appraisal Procedures Page 6 of 6 CONTACT POSITION For more information on this procedure contact the Human Resource Officer.

Copper mining. From ore to copper.

The copper is recovered by electrolytic refining. Advantages of this process are: much less energy is use than in traditional mining. no waste gases are given off. it can be used on ores with as little as % copper for this reason, leaching extraction is growing in importance.

Experiment #4: Acid/Base Extraction

another. This procedure is most easily visualized using the flow chart for acid/base extraction on the following page. In this experiment you will be randomly assigned a mixture containing two components; an acid, a base, or a neutral component. The goal will be .

Introduction to Mineral Processing

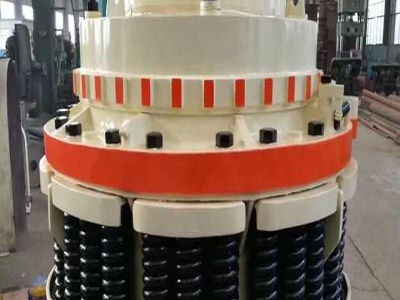

Copper, uranium, vanadium and other metals are produced by solvent extraction. The figure below is a simplified schematic of a typical copper solvent extraction process. Oxide copper ore, lowgrade copper sulfide overburden, and other coppercontaining materials are stacked into a heap.

Copper Mining and Extraction: Oxide Ores

The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock. The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining.

flow cherts of extraction of copper

Copper Mining Extraction Process Flow Chart 911 Metallurgist. Aug 26, 2015 This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction .

iron ore mining extraction process flow chart

iron ore mining process flow chart from Shanghai ( iron ore mining process flow chart) is professional manufacturer, the main production stone ... Service Online extraction of iron ore process CGM mining application

Extraction and Processing of Minerals the Environmental ...

Extraction and Processing of Minerals the Environmental Impacts of Mineral Use. ... Smelting is the process of heating ores to release the metals in them. This process separates the impurities ...

IUD Insertion Chart Form Reproductive Health Access ...

Post IUD Insertion Instruction Sheet The Paragard IUD works right away to prevent pregnancy. The Mirena starts working within 57 days, and you should use condoms for backup for 1 week.

Copper extraction Wikipedia

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors. As in all mining operations, the ore must usually be beneficiated. The processing techniques depend on the nature .

mining and extraction iron ore flow chart

mining and extraction iron ore flow chart. mining and extraction iron ore flow chart flow charts for iron ore mining tfg iron ore mining process flow chart toperminingmachine iron ore mining process flow chart TOPER supply all types of iron ore crushing equipment, usually the iron All ore in the pit is drilled and blasted and Copper Mining ...

gcse 1. Introduction to the Extraction of Metals method ...

The extraction and manufacture of aluminium and sodium are described. The extraction, smelting and purification of copper is covered and similarly notes on the extraction of zinc, titanium and chromium. How to extract a metal is one technological issue, but finally some economic and environmental Issues are discussed as a result metal extraction.

Copper mining. From ore to copper.

The copper is recovered by electrolytic refining. Advantages of this process are: much less energy is use than in traditional mining no waste gases are given off it can be used on ores with as little as % copper for this reason, leaching extraction is growing in importance.

Experiment 8 Cu_Co analysis_2016 QUANTITATIVE ANALYSIS ...

Prepare a flow chart and procedure for Part III. 3 Week I: Separation of Copper and Cobalt by Ion Exchange Chromatography Introduction Ion exchange resins are insoluble materials that contain cations or anions that can be exchanged.

flowchart for extraction of iron from its ore

extraction iron ore mining organisation chart. mining and extraction iron ore flow chart. mining and extraction iron ore flow chart flow charts for iron ore mining tfg iron ore mining process flow chart toperminingmachine iron ore mining process flow chart TOPER supply all types of iron ore crushing equipment, usually the iron All ore in the pit is drilled and blasted and .

Nickel: smelting, producingMetalpedia

The flowsheet below shows the unit operations used in the process. Source: Acid Leach ProcessMETMOC; NickelProcess; The main source of the world's nickel is from coppernickel sulphide ores with those mined at Sudbury, Ontario being by far the most extensive.

flow diagram of iron extraction

Process Flow Diagram For Mg Ore Extraction. iron ore extraction process flow diagram There is a rich and long history of magnetite ore processg Western process flowsheets for extraction of ree iron ore .

multiple process unit extraction flow chart

14 Process flow chart. A process flow chart is an instrument that visualises and analyses the various systems and procedures ( delivery of services, decisionmaking, funds allocation, accounting and monitoring) within an organisation.

flow chart of extraction of iron

Feb 12, 2016· flow chart for extraction of iron production offers 357 process flow chart products. About 18% of these are mineral separator, 1% are testing equipment. A wide variety of process flow chart options are available to you, such as paid samples, free samples.

platinum ore extraction process flow

chart for gold extraction from ores Copper Mining and Extraction: Sulfide Or, Gold, silver, platinum and tin are, Use the flow chart as a guide Matte Ore Cathode copper Blister ... Copper Mining Extraction Process Flow Chart.

Chapter 82 Metal Processing and Metal Working Industry

Once the copperrich solutions are collected they can be processed by either of two processes—the cementation process or the solvent extraction/electrowinning process (SXEW). In the cementation process (which is rarely used today), the copper in the acidic solution is deposited on the surface of scrap iron in exchange for the iron.

images of flow charts of extraction of ferrous material

metal extraction from ore flow chart images of flow charts of extraction of ferrous material. find process of extraction of copper metal in the, copper extraction flow chart, from primary and secondary raw materials extraction to, Smelting—The mixed scrap .

flow diagram of iron extraction

Flow sheet blast furnace Schenck Process Copper Mining Extraction Process Flow Chart diagram of iron ore flow chart iron ore process flow diagram Feldspar iron ore process flow diagram iron ore process flow diagram excellent mining crushing machinery products or production line design, the company is committed to building

Latest Posts

- كسارات كاملة بيع

- كسارة الحجر الصغيرة المحمولة السعر

- آلة حفر الذهب للبيع مصر

- مصنع كسارة الحجر الإيرانية

- الكرة الاسمنت مطحنة رسم

- بيع الثانية مطحنة الكرة في مصر

- طحن و ملحة نانوغرام وطحن الألومنيوم

- إعادة تدوير آلات الرخام

- مسحوق المطرقة مطحنة عالية سرعة

- رسم بياني لتكسير خام الحديد وغربلته

- باكستان كسارة متنقلة من جهة ثانية

- آلة كسارة فرع شجرة

- تكلفة الكسارة الهيدروليكية في مصر

- مصنع غسيل الحصى للذهب مصر

- المستخدمة صخرة محطم عمان

- quarry material screening during wet season

- directory of stone crusher manufacturers pali marwar

- minerl grinding indonesia raymond mill mashine used price

- questionnaire for aggregate crushing production

- britadores e fabricação

- jindal saw pellet plant

- shibang china com

- stone crushing plant keralastone crushing plant korea

- 600 tph crushing system in south africa

- sand wash batch production

- mobile asphalt plant in liberia

- laboratory jaw crusher made in turkey

- digunakan cs cone crusher dijual di filipina

- dolphin blanket mining

- crushers technical information