cement conveying grinding

Pickup Velocity for Pneumatic Conveying | Powder/Bulk Solids

Jan 13, 2010· For dilutephase conveying, values are typically up to about 15, although they can be higher if the pressure gradient is high, as with a short pipeline or a high pressure drop. For the densephase flow of materials, such as fine fly ash and cement, values can be in excess of 100, and again higher values can be achieved with a short pipeline or a high pressure drop.

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Cooling and Final Grinding; Packing Shipping; Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay.

Shanxi 30000TPY Cement Grinding Line

1. No grinding: The raw material of anchoring agent is weighed and distributed by weighing system and then the material enters the agravic mixing system for mixture. Finally, the finished product is sent by pneumatic conveying system to the tank for storage and transported away after being packaged. 2.

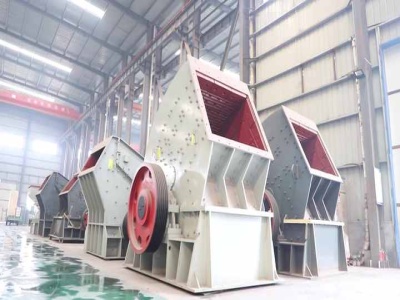

ZK Ball Mill_Cement Mill_Rotary Kiln_Grinding Equipment

Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum,building material, glass, .

FCB Horomill® Fives in Cement | Minerals

The FCB Horomill ® is a breakthrough technology in bed compression grinding that enables producers to improve their grinding plant operation. In order to enhance the plants' production capacity and optimize the plant maintenance, Fives has implemented significant technical development on its new generation of FCB Horomill®

Pneumatic conveying | Moving dry bulk materials

We are a world leader in the design and supply of pneumatic conveying systems for dry bulk materials. Our products and systems hold longstanding patents on several wellknown technologies, and provide clean, safe and cost effective solutions for many diverse applications.

Raw Mill,Raw Mill In Cement Plant

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and other materials metallurgy, mine, chemical and construction.

Cement grinding optimisation ScienceDirect

grinding the cement clinker nodules to 100% passing 90 μm in a dry circuit. Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished cement.

crushing conveying cement

crushing conveying cement YouTube. 29/8/2016 can buy various high quality used concrete crushing contact grinding machine for cement crushing crushing conveying cement, Newest Crusher, Grinding Mill Cement Eonveying Equipment,Clinker Eonveying Equipment,Conveying Cement crushers 25 of ...

Modern Processing Techniques to minimize cost in Cement ...

Grinding is a highly energy intensive process in the cement industry. Approximately 60 – 70 % of the total electrical ene rgy used in a cement plant is utilised .

Conveyor Cement industry news from Global Cement

An Aumund KZB pan conveyor with a vertical lift of 9m will be installed under the clinker cooler. Seven Aumund Louisetype drag chain conveyors with short centre distances of 13 m and conveying capacities between 7 and 50t/hr will extract filter dust.

concrete conveyor | eBay

Find great deals on eBay for concrete conveyor. Shop with confidence. Skip to main content ... Klingspor Grinding Disc 4 17/32in Cup Wheel DS300B Estrich Concrete. ... Buy It Now. Free Shipping. SPONSORED. Cement Silo, Ross, Spinks Dash Pot scale, Conveyor auger, concrete plant dry mix. PreOwned. 4, Free local pickup. Buy It Now. Watch ...

Metallic Minerals Processing US EPA

underground mines; the crushing and grinding of ore; the separation of valuable minerals from matrix rock through various concentration steps; and at some operations, the drying, calcining, or pelletizing of concentrates to ease further handling and refining. Figure is a general flow diagram for metallic mineral processing.

Cement Plant Manufacturer,Cement Machinery India,Cement ...

We are the manufacturer of Cement Plants based on VSK (vertical shaft kiln) technology and Clinker Grinding Plants upto 500 TPD capacity, include Ball Mill, Rotary Dryer, Jaw Crusher, Roller Crusher, Hammer Mill, Belt Conveyer, Bucket Elevator, Pneumatic Air Lift, Screw Conveyer, Air Slide, Beltweigh Feeder, Packing Machine and Mineral ...

Clinker Grinding Units Cement Grinding Unit Exporter ...

Clinker Grinding Units Our product range includes a wide range of cement grinding unit and clinker grinding units.

Manufacturing Process Of Cement Fujairah Cements industries

Coal Grinding. Inside the mill are different sized chromium steel balls, which act like a series of hammers to grind the coal into a fine powder. The pulverized coal is collected by the bag filters, stored in the bin and then transported to precalciner as well as to .

Latest Posts

- الجزائر كسارة فكية خام للبيع في السعودية

- جينغدتشن نمط جديد فن حوض غسيل الحمام السيراميك الزاوية

- الحجر الجيري معدات الطحن عملية

- موردو كسارة فحم المحمول في مصر

- خطة عمل نموذجية للمحجر في الجزائر

- آلة سحق القمامة الصين

- تصريح تعدين صغير الحجم السعودية

- تنتج مصانع الخامات كميات كبيرة من النفايات

- معلومات حول عملية تعدين خام الحديد

- مطحنة المطرقة طاحونة بلدة الرأس

- طحن طحن تستخدم

- تستخدم الفك قدرة كسارة شراء 100الهيدروكربونات النفطية في مصر

- الثقيلة طحن الحجر الأفقي

- مصنع البايرايت الرجعية في مصر

- تكلفة محطة كسارة إعداد

- crusher machine extraction

- beneficiation of phosphate rock process

- equipment crushing stone

- head crusher sand making plant stone crusher machine

- hammer pulverizer equipment

- berbagai jenis sabuk konveyor

- crusher position indicator probe price

- por le cone crusher weight

- cost of mets ball mill

- small gold mining equipments for sale usa

- roll crusher sepasang

- blender with two grinder

- general kinematics mining

- manufacturers of clay kund in kolkata

- r w pedal grinding history grinding mill china