cement grinding process cement grinding

Polished Concrete Floors Making Procedure and Benefits

Polished concrete floor surface is made by a mechanical process of grinding and polishing with the help of a penetrant chemical to provide different texture. The polishing of concrete is a multistep process which requires specialized tools and equipment. The chemical penetrant employed for ...

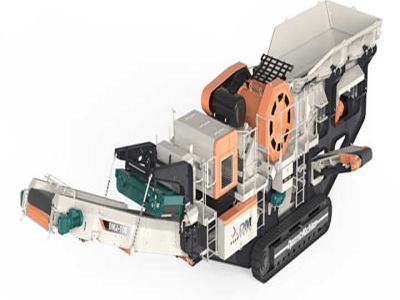

Cement Grinding Process Plant, Cement Grinding Process ...

offers 1,433 cement grinding process plant products. About 1% of these are other mining machines. A wide variety of cement grinding process plant .

Vertical Cement Grinding Mill

During the past times, ball mill is widely used in cement industry and it has brought much more profits to the cement production businessmen. In the cement industry, the necessity of continuous improvements in the grinding process and the related cost reduction has promoted the diffusion of vertical cement mills worldwide.

Concrete Grinding – Keynote Constuction

Concrete grinding is used to level out sections of concrete that are uneven or damaged due to ground movement or wear over time. Diamond grinding concrete can be a cost effective way to make surfaces safe without the expense of ripping out concrete and repouring.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

costs for cement, it is very important to optimise the existing grinding installations. Experience has shown that the potential for optimisation is greatest in the cement grinding process in a cement plant The benefits that can be achieved due to the optimisation of cement grinding system through process diagnostic study are:

Used Cement Grinding Mill Price

making cement by the chemical reaction between the components of the ground mixture. This chemical reaction occurs at high temperature in a rotary kiln, grinding the cement clinker nodules to 100% passing 90 microns in a dry circuit. Cement Grinding Mill. Zenith is global supplier of cement grinding .

How to Repair Sidewalks with Concrete Grinding Concrete ...

Concrete grinding or sidewalk cement grinding is one method to remove sidewalk trip hazards typically up to 1 1/2″ in height where sidewalks have been lifted by tree roots, shifting soil, etc. Concrete grinding will remove the top finished layer of cement and leave an exposed aggregate finish where the concrete trip area has been removed, but ...

ThyssenKrupp Industrial Solutions Cement Industry

Maximum throughput rates and drive powers, smallest possible construction size and high availability are the essential demands on a cement raw material grinding plant and also precisely the characteristics of this new roller mill from Polysius. The QUADROPOL® has decisive advantages that make it particularly suitable for online operation.

Cement Milling Understanding Cement

Cement milling and gypsum dehydration. Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris 2CaSO 2 O. On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4). This is calcium sulfate with a ...

Cement grinding with Horomill | Industrial Efficiency ...

The finished product is collected in a dust filter. The Horomill is a compact mill that can produce a finished product in one step and hence has relatively low capital costs. Grinding Portland cement with a Blaine of 3200 cm 2 /g consumes approximately 23 kWh/t and even for pozzolanic cement with a Blaine of 4000, power use may be as low as 30 ...

Cement grinding and packing process Al badia cement

Cement grinding and packing process. The clinker is ground with an amount of gypsum to a fine powder in order to regulate the setting time of cement and to gain the most important property of cement, which is compressive strength.

Teresa plant, the Philippines: cement grinding plant.

cement grinding process. The first is that it drastically reduces the potential of cement prehydration. Known drawbacks of cement prehydration are the risk of silo blockage and a decrease in cement performance. Known remedies to this loss of performance are either an increase of the cement fineness and corresponding

Concrete Grinding – Oatlands, Sydney Perfect Concrete Care

Perfect Concrete Care team members recently finished a large Concrete Grind Seal project for our client J G Knowles Associates in Oatlands. These works involved the concrete grinding of a 1,600m2 underground car park at a newly built age care facility.. Techniques Used:

Manufacturing process | Lafarge Cement, concrete ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Cement Grinding Aids

The cement grinding aids is additional material in liquid or solid form, admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption, without compromising the performance of the cement. The cement grinding is an energy intensive process. The addition of ...

The Cement Grinding Office Grinding Process Engineer ...

View The Cement Grinding Office's profile on LinkedIn, the world's largest professional community. The Cement has 10 jobs listed on their profile. See the complete profile on LinkedIn and ...

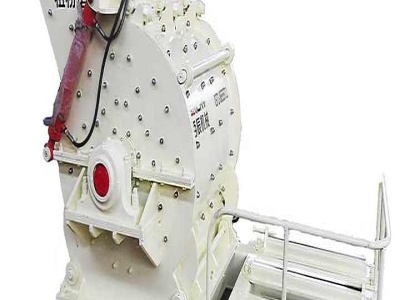

Grinding systems Fives in Cement | Minerals

The ball mill is traditionally the basic technology in a cement plant and is a very reliable machine. It is particularly well adapted to the grinding of products at high fineness, very abrasive products and solid fuels, as well as to a wide range of minerals.

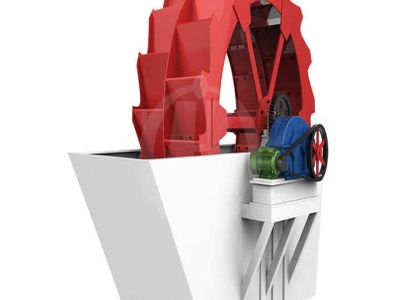

Minneapolis Concrete Grinding | Minnesota Concrete Flooring

The Concrete Grinding Process. Concrete grinding is also known as concrete polishing and it is the process in which concrete flooring is polished to a specific level of grit by a concrete densifier and grinder. There are instances where flooring needs to have grit so that the coating that follows can hang on to the concrete floor.

process in cement grinding

Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into ... Heat generated in the grinding process causes gypsum () to lose water, forming bassanite () or γanhydrite...

Cement grinding optimisation ScienceDirect

In the minerals industry, research in modelling and simulation of the grinding process has a long and successful history. However, in the cement industry, the grinding process is more of an "art" than engineering and the equipment manufacturers exclusively hold the "knowhow".

The Grinding Tips Tools You Need to Grind Concrete Floors

Introduction to Concrete Floor Grinding. Concrete floor grinding has in the recent past gained significant ground in the construction industry. It is the process of smoothening concrete surfaces and also making them glossier through the utilisation of abrasive tools.

process of cement grinding

Cement Grinding Rockwell Automation. Product 20 30 The Pavilion8 Cement Grinding Appliion offers process and quality control independent of system faced with a traditional ball mill circuit, roller press, vertical mill or combined layout, the Cement Grinding Appliion, based on multivariable model predictive control (MPC ...

Grinding plant Fives in Cement | Minerals

QNCC (Qatar) Raw meal and cement grinding plants with Bmill; Cementos Moctezuma (Mexico) Raw meal and cement grinding plants with FCB Horomill® Jingye (China) Steel slag grinding plants with FCB Horomill® Bunge Maroc Phosphore (Morocco) Phosphates grinding plant with FCB Bmill; Buzzi Unicem (USA) Cement grinding plants with FCB ...

CEMENT GRINDING | Hilger

Here, process and quality must always be deadon. Optimized plant performance and perfect process control are indispensable. Cement mills are the biggest consumers of electrical energy. Good grinding organization and intense monitoring can keep grinding cost under control. Regarding cement grinding, the focus is on the following topics:

Latest Posts

- الرمز التخطيطي للكسارة

- الكوارتز مسحوق نبات في مصر

- كسارة فكية على نطاق مختبر

- طواحين الكرة في العملية

- مطحنة الكرة المستخدمة في تكنولوجيا الطلاء

- أنواع الحزام المنقول

- المطاحن آلة prodeva المطرقة

- كسارة المطرقة Loesche

- مطحنة الكرة لوحدة طحن ومصنع الأسمنت الكلنكر

- مطحنة طحن الأسمنت مستعملة للبيع

- صغيرة محمولة كسارة الفك الصخور

- سعر الذروة محطم في مصر

- كسارة الحجر كسارة البر الرئيسى للصين

- نظام تكسير كسارة

- كسارة الحجارة المتنقلة للبيع العراق

- impact crusher brunei for sale

- granitegranite crusher typesgranite crusher uk

- stone crushers for sale in rajasthan

- servo piston

- stone crusher project sand making stone quarry

- manufactures of sbm dust masks

- pacific digital plaza china

- cost of a grinder hammer mill

- producteur de machine de fabrication de buses

- good china mineral processing equipment expo

- granite waste to replacement of river sand in concrete project

- harga mesin crusher batubara indonesia

- best operation of vertical cement grinding mills

- slag processing equipment

- stone crusher manufacturing in brazil