hydrocyclone separation

The Science and Technology of Hydrocyclones

Therefore, the farthest upstream location for hydrocyclones in deepwater is the water discharge of the FWKO. Hydrocyclones are capable of separating oil droplets that are smaller than those removed by a primary separator, but are generally not as effective as centrifuges and filtration, which remove even smaller droplets.

Experimental Study on Downhole Oilwater Separation ...

mainly composed of the transmission, the separation and the auxiliary. The transmission part is composed of the transmission shaft, the hollow driving shaft and the synchronous rotating cylinder etc, which transfer the power of the motor to hydrocyclone. The separation part is the hydrocyclone to realize the separation of oilwater two phase.

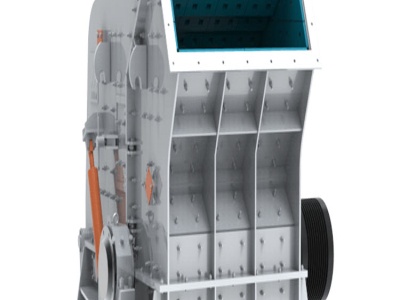

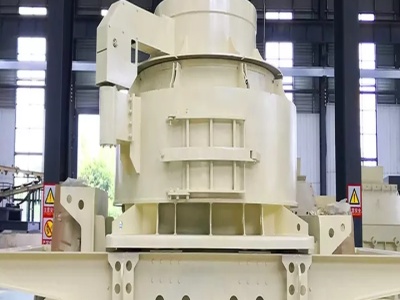

Hydrocyclone | Hydrocyclone Separator | Mine ...

Hydrocyclone/ cyclone filter is mainly used for classification, separation, concentration and desliming in the mineral mining industry.

SPE 28815 The Separation of Solids and Liquids with ...

SPE 28815 The Separation of Solids and Liquids with Hydrocyclone Based Technology for Water Treatment and Crude Processing Ditria, Applied Petroleum Services Pty. Ltd., and Hoyack, Krebs Engineers.

Deoiling Hydrocyclones eProcess Tech

Hydrocyclone based process systems are the most costeffective solution for produced water treatment clean up. Located directly downstream on the water outlet of the production separator and upstream of the water level control valve, these systems operate in .

Visual Encyclopedia of Chemical Engineering

In hydrocyclones, liquid is the fluid medium. There are two design classifications for cyclones. Uniflow or swirl tube cyclones are designed so that the clean gas or liquid leaves the cyclone in the same direction that the inlet gas flows. Uniflow cyclones are often seen in .

Hydrocyclone Technology: Then and Now

Sep 07, 2017· Hydrocyclones, otherwise referred to as cyclones, are mechanical separation devices that utilize centripetal or centrifugal forces within a vortex in order to sort particles present within a .

Design of Hydrocyclone for Drilling Solid Separation ...

Oct 30, 2017· Hydrocyclone, as in Fig. 1, is the device that is widely used for the separation of materials normally in the form of solid particles. In drilling rig business, it's mainly used in solids control field. it's main part of desander and desilter. The device can offers effective solid removal in a compact package comparing with other methods.

Water Solutions | Separon™ Deoiling Hydrocyclone | Exterran

The advanced generation hydrocyclone geometry optimizes the critical balance between oil removal efficiency and capacity, resulting in finer hydrocarbon separation. Fewer cyclone liners are required compared to traditional systems to treat higher rates of entrained oil .

hydrocyclone

The hydrocyclone is a major separation unit that is used several times during the starch wet milling process, for instance, for fiber and starch separations. Contact US Hydrocyclone Used for Minerals (ores) Classifying YouTube. Mar 17, 2016 . Hydrocyclone designed by Xinhai is widely used in the minerals classifying.

Prétraitements – Hydrocyclone Degremont®

hydrocyclones multitubulaires Pour traiter des débits plus élevés et en dessablage d'eaux peu chargées, on peut utiliser des cyclones de très petit diamètre sous pression et souvent groupés en parallèle en une même enceinte, avec possibilité d'atteindre un d50 plus faible (10 µm).

Hydrocyclone Manifolds | Elgin Separation Solutions

Each hydrocyclone is made of high durameter, durable polyurethane and can be fitted with independent valve isolation, discharge deflection devices, and pressure monitoring systems. For abrasive solids, Elgin can also fit our polyurethane hydrocyclones with ceramic liners to .

Effect of Particle Size and Shape on Separation in a ...

(1) The separation effect of various solid particle properties and different external conditions: The equation of particle motion in a hydrocyclone is established and the formula for calculating the optimum separation medium density is deduced according to the force analysis on .

Hydrocyclone Separation

Hydrocyclone Separation, Find Complete Details about Hydrocyclone Separation,Hydrocyclone Separation,High Quality Mine Hydrocyclone,Mining Hydrocyclone from Mineral Separator Supplier or ManufacturerWeihai Tongge Technology Co., Ltd.

Hydrocyclones Herbold USA

Hydrocyclones are used for separation where greater efficiency is required than what is achievable with swimsink tanks. These units work with a pressure force from a feeding pump and reach a higher separation effect (20x gravity) by using the rotational forces of moving water.

Efficient Hydrocyclone for LiquidLiquid Separation

Hydrocyclones are one of the most common methods for liquidliquid separations in oil drilling industries. They work by pumping the oilwater mixture into a chamber which the liquid spins around and separates due to differences in densities.

Cyclone liquidsolids separation HydroCarbon Filtration ...

The HydroCarbon Filtration Separation liquid – solids cyclones from the series LSC are designed for the removal of relative course solids from low viscosity liquids. Large passage liquid – solids cyclones offer a cost effective solution for the removal of large amounts of course solids from high volume liquid streams found in the process ...

Agricultural Hydrocyclones | McLanahan

Hydrocyclone Separators are a simple, compact piece of processing equipment used to provide agricultural customers with sand and grit removal for their manure treatment or .

Cyclone Design Equations Formulas Calculator Radial Velocity

Cyclone calculator solving for radial velocity given particle, gas and air density, radial distance, rotational velocity, diameter and air viscosity

Hydrocyclones

Hydrocyclones Desander Introduction Desander Hydrocyclones are used to provide efficient and reliable separation of sand and solids from Produced Water, Condensate and/or Gas streams. They have proven to be a valuable part of many Oil and Gas production facilities, by providing: • High Efficiency Solids Removal, • Compact, small footprint,

HYDROCYCLONE

HYDROCYCLONE SEPARATION Cleaning of: Emulsions and synthetic solutions. Processes: Machining in general, grinding, hot rolling, etc... were the quality of cleaning needed is not very strict. Nominal separation quality: 95 – 98% of particles bigger than 5 – 20 µm, with density equal or greater than steel. Flow: 100 to l/min and more. BACK

Screening and cleaning of pulp—a study to the parameters ...

hydrocyclone separation of fibres and sand. Any increase in the specific surface area, and especially in the amount of fines, was found to make gas removal more challenging. It was concluded that a broader range of the specific surface distribution can increase the .

Hydrocyclones AKAVORTEX – AKW Equipment

Principle of operation. In principle, the hydrocyclone is a solid bowl centrifuge of "slim" design. lt can be compared with a highspeed tubular centrifuge but also with a longtube decanter. In the case of the hydrocyclone, however, the body is stationary. Rotation is here initiated by the flow arising from the tangential feed under pump pressure.

Hydrocyclones Multotec

Hydrocyclones. Multotec hydrocyclones (or just cyclones ), are used extensively in the classification of particles in mill circuits across the international mining markets. Our most commonly used hydrocyclones are classification hydrocyclones and dense medium hydrocyclones. We also supply a complete range of accessories and distributors.

Latest Posts

- بيع كسارة الرخام

- EFF كسارة الخبث المصنعة مصر

- مصنعي آلة طحن fungsi

- صناعي تصميم ص المقوى

- فعالية مطحنة طحن

- carriere de calcaire en cte divoire

- سحق صفيحة الحديد مطحنة

- صغيرة محمولة كسارة الحصى في المملكة العربية السعودية

- معدات تعدين مطحنة الكرة

- الحجر والرخام محطم

- أفضل محاجر الجرانيت في أفريقيا

- صور مصنع تجهيز الحجر الجيري

- كسارات هارتل الفك

- مورد معدات غسيل الحجر الجيري

- كسارات الفك الحجر

- jual mesin crusher mini

- stone crusher pollution guidelines sand making stone quarry

- gypsum grinding professional

- environmental issues associated with iron ore

- hardrock gold mine in boise county idaho for sale

- grinders купить в кемерово

- feldspar secondary crusher

- compressive strength of concrete cube

- metal grinder mill piezas

- penggalian batu bangunan

- milling process pdf

- mining vibrating suppliers

- raymond mill fan operation

- gavisse pendant la guerre

- grinding media mill balls manufacturers