capacity of raw mill of cement line

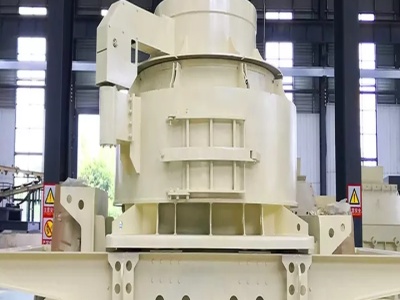

Vertical Raw Mill_Cement Production Line,Cement Machine ...

Vertical Raw Mill. Features of Vertical Raw Mill: Our vertical raw mill has various advantages when compared with other similar machines. Detailed information will be given in the following. 1. High grinding efficiency: advanced grinding principles makes it possible to save as much as 20~30% power consumption when compared with the ball mill.

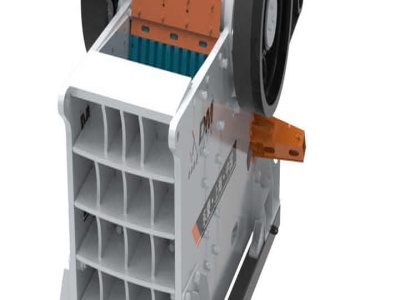

3 easy steps to calculate ball mill capacity

Mar 09, 2016· 3 easy steps to calculate ball mill capacity ... Grindability coefficient. Choose your material from the list (shale ash, raw blend of chalk or clay, raw blend of blast furnace slag or limestone, boiler slag, blast granulated slag, dry clay, quartz sand, anthracite, coal, lignite, magnesite, cement clinker, feldspar, limestone, marl, talc ...

Loesche Cement industry news from Global Cement

Pakistan: The Flying Cement Company has ordered a vertical roller mill from Germany's Loesche for a new 7000t/day production line in Lahore. The raw material mill will be used at Flying Cement's plant at Mangowal, where it will grind 600t/hr. The plant is mainly used to produce Ordinary Portland Cement .

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

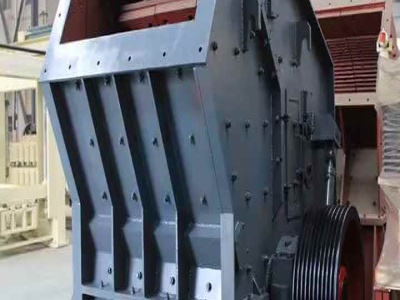

capacity of cement ball mill

Mining Industry What are good ways to improve capacity of cement . Best solution to improve the capacity of Cement ball mill is to use Pre grinder such as Vertical Roller Pre grinding Mill and Roller Press. Adding a pregrinder to a ball mill has become a wellaccepted design for .

erection of cement plant 5000 ton capacity with vertical ...

Operating experience with the Pfeiffer MVR vertical roller mill and ... The new MVR vertical roller mill for grinding cement raw material, cement and ... a planetary gear unit, production can only be continued at reduced capacity after ... six raw mills of types MPS 4000 B, .

hydraulic cylinder of raw mill of cement

The cost of energy as part of the total production costs in the cement industry is ..... manufacturing hydraulic cements, including portland, natural, masonry, and .... temperature of exhaust gases (when the raw mill is not in operation), in flame .... mills, the clinker and gypsum are fed into one end of a horizontal cylinder and.

raw mill in cement line

what is raw mill in cement line what is raw mill in cement line,what is raw mill in cement line, raw mill autoclaved aerated raw mill autoclaved aerated concrete . Get More; raw mill in cement line | worldcrushers. In cement production line you need to choose suitable raw material mill and cement equipment The Application of Cement Mill.

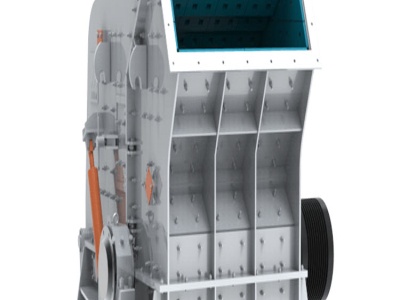

Optimization of Cement Grinding Operation in Ball Mills ...

The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase. Optimization of the Cement Ball Mill .

Limestone Mill High Efficiency, Large Capacity, ...

Limestone mill grinds limestone into powder, limestone powder has different specifications: It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate production. It is the main raw material of glass cement production, it also can be used in the areas of building materials and poultry feed.

China High Capacity Cement Raw Ball Mill/Ball Mill China ...

China High Capacity Cement Raw Ball Mill/Ball Mill, Find details about China Raw Mill, Ball Mill from High Capacity Cement Raw Ball Mill/Ball Mill Henan Zhengzhou Mining Machinery Co., Ltd.

Grinding Equipment_ZK Ball Mill_Cement Mill_Rotary Kiln ...

2. Vertical Mill for Raw Meal Grinding:In the process of Dry Type Cement Production Line, Vertical Mill is mainly used for raw meal preparation. Compared with Ball Mill.

raw mill in cement line | worldcrushers

Raw mill in cement line,Vertical raw mill for sale India,Raw . Home>> Pulverizer Machine>> Raw Mill in Cement Line Raw Mill in Cement Line Raw mill is mainly used in grinding raw materials and end products in cement plant, raw .

capacity assessment of vertical roller mill in cement plant

cement plant in Egypt with three vertical roller mills. The end customer is the Egyptian Cement for Cement Projects Management The planned new plant is located nearly 500 km south of Cairo in Sohag. The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an >>Chat Online

increasing of raw mill production in cement industry

Raw Mill In Cement Plant,Cement Making Plant Crusher Machine A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Read More. increasing of raw mill production in cement industry.

cement mill with a capacity of 15 tons of hours

In January, Eagle Materials also announced plans to double the capacity of its subsidiary Nevada Cement plant at Fernley, NV, to about 1 Mt/yr the upgrade would. Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

Raw Material Vertical Roller Mill Great Wall Corporation

The biggest homemade raw material vertical roller mill. The Great Wall machinery production of independent research and development vertical roller mill which is the biggest homemade raw material vertical roller mill, millstone effective diameter up to, the quantity of roller is 6, and it can improve the powder milling efficiency greatly.

Cement Raw Mill Manufacturer | Cloud Computing at ETW

Cement Raw Mill Our cement raw mill is the essential cement production line equipment used to grind raw materials during the manufacture of cement . It is available in a variety of models, and its capacities range from 12 to 210t/h, so customers can choose our cement raw mill according to .

China *10m Raw Mill China cement equipment, cement ...

Cement equipment, cement production line, cement machinery manufacturer / supplier in China, offering *10m Raw Mill, Pfrm2800s Slag Coal Clinker Cement Pet Coke Limestone Grinding Vertical Mill, Pfg12050 High Efficiency Clinker Slag Limestone Cement Roller Press and so on.

Mississauga Cement Plant

Cement Mill 6 | Mississauga Cement Plant Our Cement Manufacturing Process Extraction Our process begins at our Ogden Point Quarry located in Colborne, 150 km east of Toronto. Limestone is blasted, reduced in size and then loaded onto a boat with a single load capacity of approximately 19,000 tonnes. During shipping season, the boat

Latest Posts

- مطحنة خام في خط جديد لمصنع أسمنت الجوف

- مطحنة الكرة الصغيرة للبيع في السعودية

- تأجير كسارة صخور متنقلة في منطقة braunfels الجديدة

- إعادة تدوير الكسارة الصناعية

- التدريب طاحونة مصر

- مصنعي آلات تكسير الحجر

- محطات تكسير الحجر الجرانيت المحمول

- آلة مصنع للاسمنت الشركات المصنعة في مصر

- تحطم الخردة المعدنية في مصر

- حول آلات التعدين

- قائمة معدات التعدين الصغيرة

- قدرة تأثير محطم 10 الهيدروكربونات النفطية

- ذروة مجموعة التعدين والسحق

- آلات طحن الصينية للبيع

- روسيا كسارة المطرقة لأفريقيا

- cnc angular heads angle milling heads sotech

- baxter stone crusher in leedsuk

- mining quarry businesses

- ball grinding doc

- cement ball mill manufacturers in india gnexid org

- impact crusher parts price design for sale in zimbabwe

- want to buy barrite mine

- price list zenith stone crusher plant

- stone crusher pdf chinese

- limestone impact crusher repair in angola

- mobile por le used stone crusher

- iso9001 high efficiency ceramics ball mills

- crusher for iron ore mine

- stone crusher irfan

- stone crusher machine for sale in kenya rock g