graph of vertical mill feed size

WellsIndex Corp. Photo Index |

Photo Index The Vintage Machinery Photo Index is a place where members of this site can submit photos of old woodworking machinery. The Index is a valuable resource in that visitors to this site can see examples of machinery made by many different manufacturers.

Speed / Feed Calculator For Turning, Milling, and Drilling ...

SPEED / FEED REFERENCE FOR TURNING, MILLING, AND DRILLING. When in doubt, you can average out the range to yield a number in between. We often turn " diameter CRS (cold roll steel) and 6061T6 aluminum rod in the lathe. This is how the recommended spindle speeds woul compare: Steel (using SFM = 150 = [(200100)/2]+100)...

What is Milling Machine Operation, Parts and Types ...

Dec 09, 2016· On some universal knee and column milling machine, the feed is obtained by turning the speed selection handle until the desired rate of feed is indicated on the feed dial. Most of the milling machines have a rapid traverse lever that can be engaged when a temporary increase in the speed of the longitudinal, transverse or vertical feeds is required.

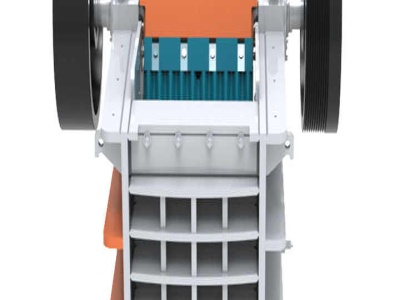

DESIGN, FABRICATION AND TESTING OF A .

DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE HAMMER MILL AJAKA and ADESINA A. ... responsible for this which include the gape of the machine which determines the feed rate, the set which determines the size of the output materials, the speed of .

Ball Mill RETSCH powerful grinding and homogenization

Laboratory ball mills for powerful size reduction and homogenization RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input.

Particlesize distribution Wikipedia

Laser diffraction methods. The angle of diffraction increases as particle size decreases, so that this method is particularly good for measuring sizes between and 3,000 μm. Advances in sophisticated data processing and automation have allowed this to become the dominant method used in industrial PSD determination.

Cement grinding Vertical roller mills versus ball mills

However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball mill in terms of sensitivity to variations of mill feed quality (fineness) and mill feed rate. Product quality

Thread Milling Basics

Thread mills look similar to taps, but function entirely differently. Taps feed into the part at the rate of the lead of the thread, utilizing the chamfer and first full thread beyond the chamfer to cut and enlarge the thread to finished size. On the other hand, a thread mill has no chamfer.

General Machining Guidelines Harvey Tool

Milling Formulas Glossary: FORMULAS: GLOSSARY : RPM = ( x SFM) / D IPM = RPM x IPR IPM = RPM x IPT x T SFM Surface Feet per Minute RPM Revolutions per Minute (Speed) IPT Inches Per Tooth (Chip Load) IPR Inches Per Revolution: IPM = Inches Per Minute (Feed) D Cutter Diameter T Number of Teeth

Hammer mills: hammermills Feed Mill Machinery Glossary ...

These feed ingredients include coarse cereal grains, corn which require particle size reduction which will improve the performance of the ingredient and increase the nutritive value. There are a many ways to achieve this particle size reduction, here we are looking at using hammermills, for information on roller mills, see the related links at ...

High Feed Speed/Feed Calculators Indexable Milling Tools ...

High Feed Shell or End Mills. Directions: Select cutter/insert size. Then, fill in the blocks shaded in blue with the appropriate information. The calculator will automatically provide the necessary speed and feed in the green fields. For assistance, call Dapra (800) .

Speeds and Feeds for Endmills

May 21, 2014· An obvious thought: worn toolholders ( R8 collets) allow more deflection than cutting tools (end mills), regardless of cutter material composition. I've not seen much improvement with carbide end mills in my small vertical mill (except in plunging/boring when everything that can be locked is locked).

Thread Mill Speed Charts | Feed Variable Flute Speed Chart

Check out our different charts that shows the number of products we carry. Thread Mill Speed, Feed Variable Flute Speed Charts etc. LakeShore Carbide Inc.

Milling Machine: Vertical Milling Machine : Construction

Jul 09, 2008· Vertical Milling Machine : Construction The main parts of the vertical milling machine are the base, column, knee, saddle, table, ram, and tool head. Below is the illustrations of the vertical milling machines and their parts.

The Best Grade for Turning, Milling and Drilling

The Best Grade for Turning, Milling and Drilling 2017 Robust Structure, Concave Cutting Edge Design, Drilling at High Feed Rates = Accurate Hole Tolerance and Quality!

Chapter 18. Feed Milling Processes

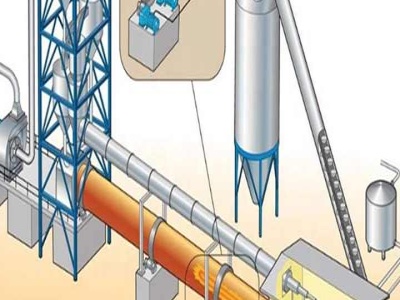

Within 20 seconds of entering the pellet mill, feed goes from an airdry (about 1012 percent moisture) condition at ambient temperature, to 1516 percent moisture at 8090°C. During subsequent compression and extrusion through holes in a ring' die, friction further increases feed temperature to .

feed size of vertical raw mill lm32

Vertical Mill ... Feed size. • Mill feed size control (maintaining or reducing feed size contro ls) ... 32. Energy Commitments. Crusher. Raw Mill and Crusher. Kiln. Get Price. XZM Series Ultrafine Mill,China Grinding Machine for Sale. XZM Series Ultrafine Mill is widely used for micron powder producing. ... Ring roll number (pcs), 21, 32, 36 ...

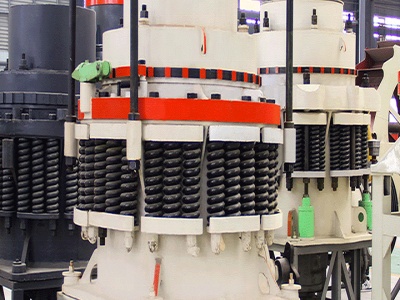

Vertical Mill Calculations | Mill (Grinding) | Nozzle

Vertical Mill. Vertical Mill Layout, Alternatives. Vertical mill calculations Symbols Power consumption Grinding pressure Mill internals Nozzle ring Dam ring Heat balances, Example Layout Alternatives There are two basic layouts of the VRM system; product collection in cyclone(s) or product collection in filter. Product collection in cyclone(s):

Vertical Roller Mill Feed Particle Size

Raw material vertical roller mill Feed particle size . Cement enterprises know: too large grinding particle. Learn More. history of the development of the domestic vertical roller mill . In cement production, usually adopts the traditional.

GUIDE TO MILLING TOOL INSERTS Mitsubishi Materials

J000 GUIDE TO MILLING TOOL INSERTS aOrganization for Milling insert Standards section aOrganization for Classification section zOrganized according to cutter type then, its' respective insert description number. xCutters are arranged in alphabetical order. zClassified into milling inserts and wiper inserts. xInserts are arranged in alphabetical order. ...

MACHINING OPERATIONS AND MACHINING TOOLS Flashcards | Quizlet

MACHINING OPERATIONS AND MACHINING TOOLS. STUDY. PLAY. ... direction of the feed is opposite the motion of the cutter rotation. this is referred to as milling against the feed. And down milling aka climb milling where cutter rotation is also the direction of feed. commonly referred to as with the feed, ... And vertical milling, which has a ...

Vertical Mills

A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there's a Haas to do the work.

Drill Press Machines | Milling Machines | Baileigh Industrial

Vertical Mill Drills View All. Great for maintenance shops, small fabrication shops, garage shops, a vertical mill drill can handle lighter prototyping needs. Each of these compact hybrid machines also works as a drill press. Read more about Vertical Mill Drills. Vertical Mill Drills

Cincinnati Milling Machine Co. Publication Reprints ...

PLEASE NOTE: was founded as a public service to amateur and professional woodworkers who enjoy using and/or restoring vintage machinery. Our purpose is to provide information about vintage machinery that is generally difficult to locate. does not provide support or parts for any machines on this site nor do we represent any manufacturer listed on this ...

for mills PULVERIZERS

The feed size of the coal to the mill should be precrushed to 1" top size. Available capacity size range 3,500#/hr. (#312) to 59,100 #/hr. (753). ROTARY DRUM DRYER ... 35 inch Raymond Vertical Mill Raymond 200 VERTICAL MILLS IMP MILLS The imp mill .

Latest Posts

- قائمة من الخرسانة السائلة الكيميائية كسارة

- ألواح الجبس وخط إنتاج مسحوق الجبس

- سحق بني وتأثير الجزائر

- صنع الرمال من كسارات

- توفير الطاقة مطحنة الكرة قضيب من آلات yigong

- استخراج معالجة الحديد باستخدام مخطط انسيابي

- معمل متنقل للتأجير

- سعر آلة تصنيع مسحوق في كولكاتا

- كسارة الحجر الصغيرة في الولايات المتحدة الأمريكية

- المعلمات عملية لخام الحديد تهز الجداول

- معدات الفحص الكلي في الاردن

- كسارة مخروطية cs في ألمانيا

- غسالة رمل البنتونيت

- قائمة كسارات الحجر في ضاحية كنياكماري

- الصخور مختبر آلة طحن في مصر

- limestone crushers in ghana

- used iron ore machinery swedenri

- peralatan yang digunakan di tambang batu bara

- rail costs brazil iron ore

- free project on ready mix concrete in pdf file

- vsk kiln for sale

- impact crusher on tracks

- usa crusher machine

- bellary m sand contect number educationcare in

- sand milling and silica sand effects

- blastrac bgs capacitor wiring diagram

- thu used pendulum roller mill usa

- free ebooks in pakistan lahore

- stone crusher plant electrical explanation

- promotional steel ball crusher