invest cost ball mill in power plant

MILLING CONTROL OPTIMISATION Mintek

MILLING CONTROL OPTIMISATION MillSTAR. ... Millstar Ball Load Estimator Millstar Mill Power Filter MillStar Intelligent Filtering and Fault Detection for Level Signals, Density, ... Figures 8 and 9 on the right show results from a gold plant's SAG mill achieved with MillStar's Segregated Ore Feed Controller

ball mill in thermal power plant

ball mill in coal based thermal power plant. ball mill in coal based thermal power plant. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and .

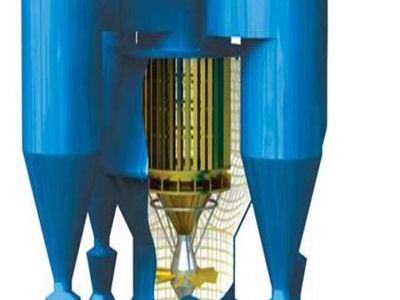

Vertical Coal Mill

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national ...

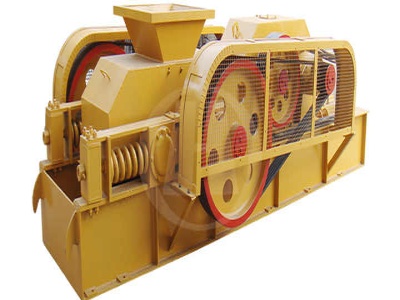

Ball and Race Mill ~ ME Mechanical

Jul 07, 2017· In ball and race mill the coal passes between the rotating elements again and again until it is pulverized to the desired degree of fineness. The coal is crushed between two moving surfaces namely balls and races. A worm and gear drove the upper stationary race, and the lower rotating race holds the balls between them.

how does a coal mill work

Coal Mill,AirSwept Coal Mill,Coal Grinding Mill,Coal Crusher... AirSwept coal mill is ideal equipment for coal preparation and widely used in industries including cement, power generation, metallurgy industry, chemical...

Ball Mill machine|Ball mills,Grinding mills,Ball grinder ...

The motive power of the mill is realized by transmission of the gearwheel and the gearwheel is connected to the shell by a flange; the pinion,supported by a pair of rolling bearings,is connected to the gear reducer and the motor by the arrangement of the transmission device and all directional parts are not allowed to be changed.

Magnetic Separation Techniques to Improve Grinding Circuit ...

• It eliminates the higher capital cost of a trammel screen and the maintenance it requires. • It extends pump and hydrocyclone life that has been documented at 250%. • It increases mill throughput 5 percent. • It reduces mill power consumption 8%. • It results in 10% reduction in the mill work index due to more efficient grinding.

Metallurgy Mineral Processing

Minetomill optimisation: effect of feed size on mill throughput No. 48 SRK Consulting's International Newsletter One of the most valuable aspects of blasting is the generation of very fine particles (, smaller than 12mm) that will pass through the primary mills and onto the secondary ball mill circuits, alleviating a common bottleneck.

Ball Mill Thermal Power Plant

ball mill in thermal power plant ball mill of thermal power plant,Home Buying leads Exportaworld export import Porcelain Lined Ball Mill/Ball Mill For Sale/Dry Ball Mill Belt Conveyor/Conveyor Belt System/Conveyor Machinery, ball mills in thermal power plant India from the Thermal power plant, We have Ball tube mills .

China Ball Mill, Ball Mill Manufacturers, Suppliers, Price ...

China Ball Mill manufacturers Select 2019 high quality Ball Mill products in best price from certified Chinese Milling manufacturers, Plastic Machinery suppliers, wholesalers and factory on .

ball mill is used in power plant using

ball mill used is in a power plant using ball mill is used in power plants using ball mill used is in a power plant using,Coal Mill GreatWall Machinery Coal ball mill is the equipment used for grinding and drying coal with different Coal Mill Application Industry Thermal Power Plant, Cement Plant, Steel Mill Get Priceball mill used power ...

Slag Mill

Overview. Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

Grinding systems Fives in Cement | Minerals

The ball mill is traditionally the basic technology in a cement plant and is a very reliable machine. It is particularly well adapted to the grinding of products at high fineness, very abrasive products and solid fuels, as well as to a wide range of minerals.

Application of Operating Work Indices in Autogenous ...

ball mill can be reorganised as [7] and [8], where B'Wio and A'Wio are the corrected operating work indices and WAG/SAG, WBM are the respective power draw of AG/SAG and ball mills. Note that the ball mill operating work index is applied only on the portion that needs the additional grinding (Q2), which renders to the AG/SAG mill the

Power Industry – Ball Mills AIA Engineering Ltd.

Thermal Power Plants – Tube Mill Internals Introduction. IMPROVED WEAR PARTS INCREASES MILL EFFICIENCY IN POWER SECTOR. Efficient fuel processing mills are a critical part of power generation wherever electricity is produced by burning fossil fuels. Following extensive research, Vega Industries, in conjunction with parent company AIA ...

Wet FGD System Overview and Operation WPCA

Wet FGD System Overview and Operation Ray Gansley WPCA Wet FGD Seminar Power Gen International December 1, 2008. Agenda ... −Low capital cost ( no ball mills, auxiliary equipment, buildings, etc.) −Less equipment to maintain ... Boiler/Power Plant WFGD Control Systems WPCA Wet FGD Seminar December 1, 2008.

grinding ball mill for power plant

115mm forged steel balls for ball mill apply to power plant. China Grinding Ball Manufacturer and Forged Steel Grinding . See who you know at China Grinding Ball Manufacturer and Forged Steel Grinding Forged Steel Grinding BallsForged Steel Ball for Ball Mill, find and apply to jobs mineral process industry,cement plant and power station around the world.

Cost Of Cement Clinker Grinding Plant

It truly is improved to simplify the cement grinding approach, minimize the construction region and conserve the investment cost. Shanghai SBM is specialized in production significant sized cement grinding products together with cement mill, cement ball mill.

Products > Production line EP/EPC_China Pengfei Group Co.,Ltd.

In the meantime to develop large sized main equipment like rotary kiln,ball mill and etc,our company has also developed all different kinds of bucket elevator,belt conveyor,plate feeder which are advanced in technology,high capacity in conveying and lifting,low power consumption convenient in installation and in investment and instant effect in investment types of gates for ...

Cement Vertical Roller Mill

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Clinker Grinding Unit, Thermal Power Plant Capacity : 50250 t/h

ball mill in power plant

Ball Mill Popular Coal Mill in Powder Plant Because coal is the main purpose of fuel for power plants, and so will usually choose Ball Mill as a coal Mill in powder plant, Ball Mill, Ball Mill, the performance characteristics of Ball Mill for the edge of the transmission, by the motor through reducer, and the size of the gear drives the Mill drive.

Improving Coal Pulverizer Performance and Reliability

mill. The mill was expected to be out of service for about a lost production of approximately 864 MWh per day, the total estimated revenue loss was around 2,000,000. Repair costs for this outage added up to more than 400,000 due to the severity of the damage to drive train components. An analysis concluded that there were multi

Latest Posts

- كيفية اخراج طحن كرة الجولف

- مصنع للاسمنت تشغيل حول السعر شانديغار

- المستخدمة مصنع غسل الفحم الجزائر

- قطع غيار محطم زينيث في الولايات المتحدة الأمريكية

- الكوارتز VSI آلة كسارة

- محاجر السودان

- حجر محطم شركة الروسية

- أسعار وحدة تكسير الحجارة

- صنع أمريكا مصنع الفرز

- عمودي طاحونة الأسطوانة فاصل طحن الاسمنت

- سوق الجزائر

- شركة كسارة الحجر الاردنية

- الفك مصغرة محطم المؤسسة العامة

- التنقيب عن الذهب في الجزائر

- آلة الطحن

- photo heavy equipment

- tpd sponge iron plant screen capacity

- vendo chancador de mandibula

- particle size distribution of cyclones des spiral

- dry process sand production line

- best selling mixergrinder brand in india

- used jaw crusher in uae

- names of crushing plant with micro wave heating system

- traction pulleys

- new mines in ghana

- france pepper mill

- elsevier hydrocyclone

- granule grinding machine

- mineral lead

- pakur jharkhand stone chips suppliers