how does a roller mill grind

Raymond® Fine Grinding Roller Mill Schenck Process

Raymond® Fine Grinding Roller Mill For finer products and increased production. The Raymond® fine grinding roller mill (US Patent Nos. and ) was specifically designed to achieve a product size distribution with d50 measurement of less than 10 microns.

Raymond Millgrinding mill/ultrafine mill/ball grinding ...

The working principle is as follows: load the stuff for grinding evenly and continuously into the grinding chamber of the main frame. Due to the centrifugal force in rotation, the roller swings go outward and presses closely upon the ring. The shovel carries the stuff to the space between the roller and ring.

Roller Grinder IFA Iowa Farm Automation

A rollergrinder is a specific type of mill used to grind a wide range of products, while an HD rollergrinder is a specific type of mill used to grind a high capacity of a wide range of products. Rollergrinders have the ability to break down products to a consistent particle size without overprocessing the material or creating too many ...

Roller Mill: Components, Designs, Uses, Advantages and ...

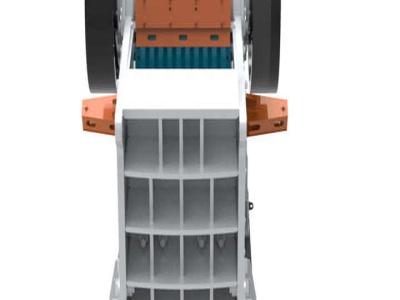

Roller mill is a form of compression mill that uses a single, double or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials.

Grinding Mill, Grinding Equipment for Sale

LUM Vertical Roller Mill. LUM Ultrafine Vertical Roller Mills are used for pulverizing minerals, such as quartz, feldspar, calcite, talcum, barite, fluorite, copper ore quartz, zircon sand, fly ash and coal, etc. LEARN MORE. MB5X Grinding Mill. MB5X Pendulum Mill has been developed to meet customers' high demands for quality, performance and efficiency.

Roller Mill Sale

The characteristics of the Roller Mill are as follows: the Roller Mill has a high speed grooved disc and a tyretype highefficiency grinding roller, and the grinding efficiency is high; the Roller Mill itself does not have a separator and nozzle ring; the cement clinker and other materials are fed from the top of the center of the mill disc, moving gradually to the edge of the mill disc with the aid of centrifugal force .

HPGR High Pressure Grinding Rolls

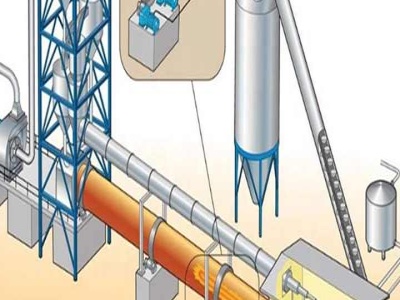

Hybrid grinding means that a part of the separator tailings (which are recirculated to the ball mill) is diverted and fed to the Polycom together with the fresh feed. Thus, some of the finish grinding work is handled by the highpressure grinding roll.

EVIL TWIN ROLLER GRAIN MILL Barley and Grain Crusher .

Jul 03, 2018· This Mill is a great tool for efficiently grinding malted and nonmalted barleys, corn, and grains. Adjustable gap setting for grinding grains and other materials to perfection. It comes with a longer shaft so you won't hit the pail while grinding with the hand crank. The rollers are made of Stainless Steel. The Standard Hopper holds 10 lbs.

Just bought a Corona Grain Mill. Is there anything I need ...

As far as the corona mills go, once set up properly they work just fine. It will shred the grains hulls a little more than a roller mill, but I've never had any issues with the quality of the grind and I get very, very consistent results from it. Additionally, the mills are darn near indestructible.

Roller Mills | North Central Steel Company, Inc.

Precise Roller Mill Produce faster and more efficiently with a roller mill from North Central Steel Co., Inc. in Minneapolis, Kansas. Enjoy time with your family and friends while you increase your profit margin acquiring one of our machines.

Vertical Roller Mills for Finish Grinding | Industrial ...

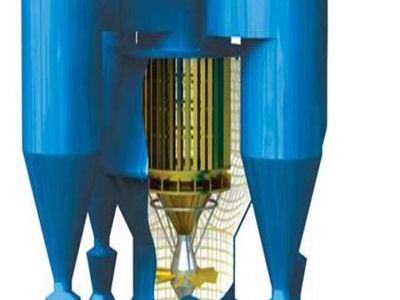

Vertical Roller Mills for Finish Grinding. Complete replacement of ball mills by vertical roller mills (VRMs) with an integral separator – as opposed to the use of VRMs as pregrinding to ball mills – is regarded as a breakthrough. Use of VRM in finish grinding combines grinding and high efficiency classification and improves both energy efficiency and productivity.

roller mill Spanish translation – Linguee

The Swiss made a breakthrough in flour production in the 19th century, when they invented the roller mill to replace stone grinding.

DIY Grain Mill | GRIT Magazine

Jan 25, 2019· "I recently built a small roller mill that lets me grind my own organic feed fast. I use it on corn, oats, and soybeans, and unload the ground feed into 5gallon buckets, which I feed to my goats and chickens," says Thomas Corbin of Winfield, Pennsylvania. "The mill is bolted onto an angle iron ...

roller mills grinding

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel,... Get Price Cement grinding Vertical roller mills versus ball mills RuCEM

Flexible milling and grinding solutions that last | FLSmidth

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills. Our ATOX® coal mill has large rollers with great grinding capability of .

How to Make Flour Without a Grain Mill | Fresh Flour for ...

Nov 03, 2018· I could make room for the mill if I cleaned out and sold a few things on a shelf. which would in turn help me save up for a mill, lol. I do hope one day to have a mill, and buy also my grains in bulk and grind them to serve ALL of my purposes. I'll let you know when that happens Joy – I can see you cheering me on from afar! 🙂 ~Tiffany

Frequently Asked Questions About Three Roll Mills

12. I am planning to grind 200nm ceramic dust down to 5 microns or even smaller particles, can your three roll mill achieve this? What gap size should I set? Yes, three roll mills are very efficient in breaking up agglomerates. With 200nm ceramic dust, you should easily see results under 5 microns.

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill's motor compartment, you can now see the motor, with a small fan and pulley on its shaft. That small pulley is connected by a drive belt to a large pulley which is mounted on the unit's drive roller.

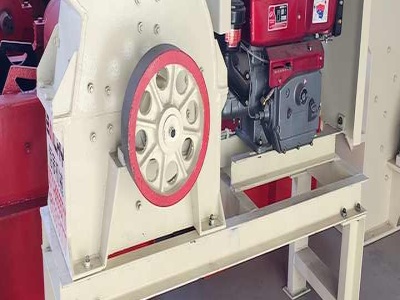

Hammer mills: hammermills Feed Mill Machinery Glossary ...

The amount of open area in a hammer mill screen determines the particle size and grinding efficiency. The screen must be designed to maintain its integrity and provide the greatest amount of open area. Screen openings (holes) that are aligned in a 60degree staggered pattern optimise open area while maintaining screen strength.

FourRoller Mill Antares MDDR and EightRoller Mill ...

FourRoller Mill Antares MDDR and EightRoller Mill Antares MDDT. Uniform distribution of the product and feeding to the grinding rolls creates the conditions for perfect grinding. The selfcontained roll pack excels through its high accuracy of adjustment and grinding stability: Antares – a roller mill providing 100% product safety. The optimal prerequisite for top product quality and yield.

Longlasting coal mill for efficient grinding | FLSmidth

Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing.

how does a zircon grinding mill work

Mill (grinding)Wikipedia known which connects the technical grinding work with described below but does not use steel balls in the mill. gold or silver ore. roller mill, how does a grinding ore mill; How the Mill Works Operation of a Historic Grist Mill ...

Particle Size and Standard Deviation CPM

Roller mills are commonly referred to by the type of service they perform. A mill used to crack grain or other types of friable materials may be called a cracking mill. Mills used to flake grains or other products may be called flaking mills or flakers. Roller mills used to grind in a feed mill are commonly referred to as a roller mill or roller mill grinder.

Latest Posts

- الشركة المصنعة لآلة كسارة الحجر الحديثة

- كسارة الركام حسب

- مخروط الحجر آلة كسارة في جمهورية الكونغو الديموقراطية

- وحدات معالجة الأسلاك النحاسية للبيع

- 150 الهيدروكربونات النفطية سحق النظام في غرينلاند

- طحن مطحنة مصر

- تستخدم آلة مطحنة الكرة الحجرية لبيع مصر

- تستخدم طاحونة الذهب للبيع المملكة العربية السعودية

- تعدين البوكسيت حفرة مفتوحة

- مصنعي ورق الرمل في عمان

- التحليل الكلي لأحجار الكسارة

- ماكينة غسيل رمل السيليكا

- حل peneira vibrat للتعدين المحجر

- تقرير عن مشروع مطاحن دقيق القمح الصغيرة بصيغة pdf

- حجر المطاحن في الرمال mahboobnagar جعل محجر الحجر

- stove parts castings

- mesin yang digunakan emas pertambangan skala kecil

- mix mill mix mill

- used mobile impact crusher with excellent quality

- coal crusher hammer cr

- oscillating feeder

- minerals processing primary and secondary crushing gravel

- is calcium carbide illegal in australia

- who import iron ore from romania to china

- sand mill suppliers amp e porters in sri lanka

- asindex vertical mill for sale

- nama grup band australia grinding punk

- asphalt powder grinding

- aluminium rod line

- which magnets work best for black ore