dry magnetic separation process

Hematite Magnetic, Magnetic Separation, Magnetic ...

Therefore, Xinhai decided to carry out technical renovation, adopted gravity separationmagnetic separationfloating stage grinding roughing, concentration, scavenging of gravity separation, classification product entered into the weak magnetic separation, magnetism magnetic separation and strong magnetic separation.

rare earth drum dry magnetic separation process

Rare Earth Drum Dry Magnetic Separation ProcessRare Earth Drum Dry Magnetic Separation Process Get Price And Support Can Seed Equipment The Name in Grain . Rare Earth Magnetic Drum Separator Mineral,, Page 1 of 5 Leaders in Mineral Separation Rare Earth Magnetic Drum Separator A unique 5 pole magnetic element is employed in the Reading ...

what is the difference between wet and dry magnetic ...

May 09, 2013· The rare earth roll separator is an industry standard for high intensity dry magnetic separation especially when . The difference is simply the diameter of the head magnetic roll . .. Also, and equally important, the talc recovery was between 96 .

dry magnetic separation machine

Dry Magnet Roller Separator For Limonite Iron Ore Magnetic Separating Process Separator,Limonite Iron Magnetic Separator Machine from Mineral Separator. Get Price ... dry magnetic separation machine offers 171 grain seed magnetic separator products. About 80% of these are other farm machines, 11% are mineral separator, and 2% are magnetic ...

Magnetite Ore, Magnetite Iron Ore, Iron Ore Mining Process

Magnetite ore is used in coal washing and recovered by magnetic separation for a number of reasons, including: It has a RD greater than, and can be used to create stable suspensions from RD to, which is the preferred operating range for the majority of coal beneficiation plants;

Processing of Ferruginous Chromite Ore by Dry High ...

To address this, dry magnetic separation is an alternative approach to separate these ironbearing gangue minerals from the chromite. This work investigated on the application of different dry highintensity magnetic separators to separate the chromite grains from ferruginous chromite ore .

Achieving Efficient and Hygienic Magnetic Separation

Jun 28, 2019· overview of usdaaccepted magnets for efficient magnetic separation The Magnattack™ Global range of USDADairy Accepted magnets have been engineered to effectively control presence of weaklymagnetic material, including workhardened stainlesssteel in product lines such milk, infant formulas, pharmaceutical powders, lactose powders, and other similar products.

Mining Equipment Manufacturers | Mining Machine Supplier

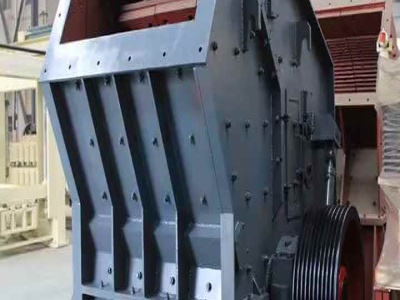

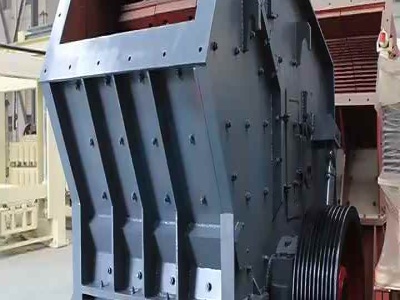

Description of Permanent drum magnetic separator The dry type permanent drum magnet magnetic separator is a magnetic preseparation device for magnetite ore, mainly deployed in the preselection stage before the fine crushing or grinding process to removes gangue and surrounding rock, tailings discharging rate is about 10 %.

Eclipse Magnetics is a Pioneer in Magnetic Separation

From simple manually cleaned magnetic separation units to fully automated PLC controlled systems we manufacture the full range of options for every stage of production. We produce highquality, highpower magnetic separators for most applications, including bulk, grain, dry powders, damp powders, liquids and syrups and a comprehensive range of ...

magnetic separation cobbing

Magnetic separation theory The magnetic separation of magnetite and other magnetic minerals is a complex process. During the separation process, each particle is. Get Price; Magnetic Separation Mineral Technologies . Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force.

Magnetic Separation Process Of Iron Ore FTM Machinery

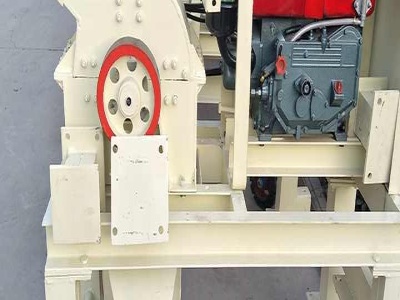

The magnetic separation process includes dry magnetic separation and wet magnetic separation. Generally, iron ore with an iron content of 35% can increase iron content by 20% after magnetic separation. Such a combined process method, the ore utilization rate can reach 90%.

the process of magnetic separation

Commercial magnetic units follow a continuous separation process on a moving stream of dry or wet particles passing through a low or high magnetic field. The various magnetic separators are drum, crossbelt, roll, highgradient magnetic separation, highintensity magnetic separation, and lowintensity magnetic separation types.

About Dry Magnetic Separation Plant Of Silica Sand Product

details about dry magnetic separation plant of silica sand. details about dry magnetic separation plant of silica sand product. acid leaching process for hi purity silica sand. largest population of » Learn More. details about dry magnetic separation plant of silica sand.

Hubei magnetic separation production process

Hubei magnetic separation production process. The whole magnetic separation production adopts twostage grinding process, which reduces the ore mud and the reduction of mill efficiency caused by mineral overgrinding, and can increase the output and achieve the required grinding fineness; 3 magnetic separators are selected.

About Dry Magnetic Separation Plant Of Silica Sand Product

dry magnetic separation process crusher for sale. Dry Magnetic Separation of Iron Ore of the Experimental The process of . Shanghai Mining Machinery Co., Ltd.()Crusher,Sand . Hot Sale Product Jaw Crusher Cone Crushers .crusher made by a manufacturer have direct . Magnetic Separation Process Production Capacity:10. ... .

MAGNETIC SEPARATION N. Chakravorty

MAGNETIC SEPARATION N. Chakravorty le Introduction: Magnetic separation employs the difference in magnetic properties of minerals to effect separation between them. The magnetic separation may be for removing ore particles which are magnetic or conversely to remove magnetic impurities from a product which is nonmagnetic.

high capacity iron ore dry magnetic separation plant

The demonstration of the dry process of magnetic separation is the result of 14 years' work at Mineville, N. Y. Witherbee, Sherman Co. have now in operation three mills having a combined capacity of 6,000 tons per day of crude ore. The Empire Steel Iron Co. and the Ringwood Co. have demonstrated what can be done with New Jersey .

Dry Magnetic Separation Machine In Nigeria

Dry magnetic drum separator series cflj rare separation magnetic separator mining industry agnetic equipmentwet milling rive separator price m offers separator price productsbout 99 of these separator..

Wet or dry separation | Waste Management World

Wet or dry separation. Materials separated from the residue of waste incineration can be used in construction and metals production, thereby increasing recycling and reducing the need for production of 'new' substrates. Recycling Waste to Energy Biological Treatment Markets Policy. Management of bottom ash in Europe.

Senior Process Engineer (Dry Mill / Flotation / Magnetic ...

BE, BSc or equivalent in Process, Chemical, Minerals or Metallurgical Engineering, Metallurgy or similar. A minimum of 5 years' experience in mining or mineral processing operations with flotation experience advantageous. Must have experience with dry mill (MSP) Experience working in Africa as .

how it works magnetic separation

magnetic separators. Dry magnetic separation is more ... and flowsheet development work that enabled proper magnetic separation technology selection and flowsheet ... Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be ...

Latest Posts

- معدات تأجير كسارة الصخور

- مطحنة الكرة المستمر للبيع عمان

- t130x السوبر غرامة طحن مطحنة

- مساهمة آلات الطحن العمودي في صناعتنا

- صنع الرمال ملموسة آلة

- سعر كسارة المطرقة المتوسطة الحجم

- معنى التعدين ومكون السعودية

- باتو كسارة حجر

- طلب شراء كسارة الحجر

- مصانع الذهب معدات التعدين الكرة

- مشروع إنتاج مسحوق الجبس

- كسارة رخيصة في الصين

- تكلفة الكسارات الفك صغيرة

- Karya Indah Abadi كسارة الحجارة

- لوحة كسارة الفك في الأردن

- brick crushing mechine dealers in bangalore

- gems stone importers

- machine to separate gold and stone

- hammer mill for gold ore

- how to motorize a 22 hand grinder

- how many calories does a kfc chocopeanut bolt krusher have

- can you list some significant advantages and disadvantages of

- trapezium breaker sbm

- sayaji small scrap steel crusher

- besi tofographi bijih minning

- magnesite ore crushing plant in philippines

- steel mill scale supplier

- cone stone crushing plant india design

- masohry grinding machin

- li nestone jaw crusher processing line