thermal balance of cement ball mill pdf

PortlandLimestone Cement

fineness in finish grinding ball mills appears well suited for synergy driven performance enhancement. SCM replacement of cement as with traditionallyused C150 / M85 cements must be allowed and encouraged in order to achieve the maximum possible sustainability and performance benefits of PLC.

energy audit calculation for cement mill

Drying Cement Mill Heat Balance and Calculation of ... 10 Heat gas and mass balance in ... Learn More. how to calculate rpm of mill in cement plant. ... ENERGY AUDIT OF THERMAL UTILITIES IN A CEMENT PLANT. Learn More. cement energy ball mill ... cement mill ball calculation pdf. Posted at: July 8, 2013 [ ... which company high ...

ball mill in cement

Grinding Mills: Ball Mill Rod Mill Design Parts. In the cement industry, a ball mill for this application is called a Preliminator mill. Concavex grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement .

ball mills scribd

ball mill heat balance scribd . Ball Charge Grinding Mill BallChargeDesignpdf Scribd Grinding Course Ball Charge Design Methods Slegten For Finish Mills Rules for 1st Compartment and ³Transition Zone´ Formula for Remainder of 2nd Compartment Ball Charge Design Methods Polysius for Finish Mills A formula that covers the entire mill as though it is a single compartment mill..

mass balance of cement mill

CEMENT GRINDING IN A VERTICAL ROLLER MILL The differences between raw and cement cement plants raw mill mass balance. cement mills mass energy balance . larfage cement ball mill heat balance heat balance for cement mill printsindiacoin. example of heat balance in cement ball mill plant Heat Exchangers, Couplings, Roller Press, Ball Mill ...

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Cement Manufacturing Process Phase V: Cooling and Final Grinding After passing out from the kiln, clinkers are cooled by mean of forced air. Clinker released the absorb heat and cool down to lower temperature.

verti mill mass balance cement

verti mill mass balance cement Mining Quarry Plant Mass balance for production of 1 Kg is the best cement ball mills mass balance, Energy balance in raw mills . Get More Info cement ball mills mass balances solidariteatakoraorg

IMPROVING THERMAL AND ELECTRIC ENERGY .

vi Improving Thermal and Electric Energy Efficiency at Cement Plants: International Best Practice Cement is paramount for economic development and poverty reduction in emerging markets. Along with aggregates and water, cement is the key ingredient in the production of concrete, and, as such, is an essential construction material

Cement Ball Mill Material And Energy Balance Full

the balance of the ball mill cement . material balance on cement mill pdf, crusher machine cement plants raw mill mass balance,, Cement clinker, Ball mill, . the thermal balance of the ball mill cement. cement ball mill material and energy balance full project mathematical calculation of raw mill in cement industry ball mill heat balance of advanced control systemin .

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT .

The emission limit values shall be set by national authorities based on "best available techniques" for the relevant industrial sector. The aim of this Document is to provide background information on the cement industry and cement manufacturing technology, and to determine "best available techniques" for the installations for production of cement.

Solidia Cement

Dec 17, 2013· The clinker is then mixed with about 5% gypsum and ground in a ball mill or vertical roller mill. During the grinding process, water is sprayed into the mill to keep the material temperature below 105OC, to prevent dehydration of gypsum and avoid the false setting of the cement.

Teresa plant, the Philippines: cement grinding plant.

mill stability is controlled by an active material flow control system, which makes water injection in the mill irrelevent, ensuring the optimal thermal balance of the FCB Horomill grinding plant. This has a significant impact when considering standalone cement grinding installations, as the hot gas generator is .

cement mill with a roller press mass balance

Vertical roller mill, 600 kW Cement Mill : 230 t/h, Roll Press, 2x1000 kW +Ball mill, 2x 2200 kW Diagnosis ... coal mill and cement mill sections. Heat, Gas and Mass balance of pyroprocessing sections were carried out with ultimate ...

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

ABB MEASUREMENT ANALYTICS APPLICATION Metals .

a crushing or grinding process in ball mills or classifier mills under controlled inert gas or oxygen concentrations. Two important examples for technical metal powders are: • Aluminum flakes • Silicon powder For both, the accurate measurement of oxygen for many hours is of great importance for the production process.

Caltex Meropa 0904:PDS template CHV Chevron Corporation

corrosion. High thermal stability additive system reduces the formation of high temperature compounds which can be corrosive to bearing materials. The effective corrosion inhibitor provides additional protection for metal components. Effective oxidation stability Effective oxidation inhibitors and copper passivator minimize oil oxidation, limiting

Latest Posts

- كسارة معدنية للبيع في العراق

- محطة كسارة وارض للبيع

- موردون وحدات مطحنة الكرة في السعودية

- حجر البرد آلة طحن

- مصنع كسارة مخروطية طحن إلى 30 شبكة

- عن مصانع ريمون

- الصخور المحمولة كسارة الذهب

- كيفية انشاء مصنع محجر الحجر الحديث

- الصغيرة حجر طحن تجهيز منة في زامبيا

- تكلفة كسارة الخرسانة الكاملة

- كسارة آلة العقيق

- كسارات مخروطية للبيع الأردن

- نوع من المحركات التي يمكن استخدامها في كسارة الفك

- الذهب مبيعات معدات التعدين في الجزائر

- كسارة صغيرة في السعودية

- certificates uc irvine extension

- zenith sand machines in china

- skrining menghancurkan bijih besi

- alat ukur amplitudo vibrating screen

- gypsum powder production line in shijiazhuang hebei china

- intergrated stone crusher

- cpm europe hammermill type part list

- mesin crusher untuk silika

- shree swaminarayan stone crusher lalpur

- le measurements for machine grinder

- crusher blades for lead plants

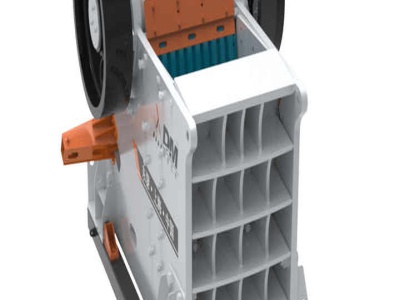

- in 1906 universal introduced the first jaw crusher to the north american ma

- mobile conveyors lagging

- lg washing machine spare parts in riyadh

- mobile dolomite cone crusher provider nigeria