line diagram of cement mill grinding media loading

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

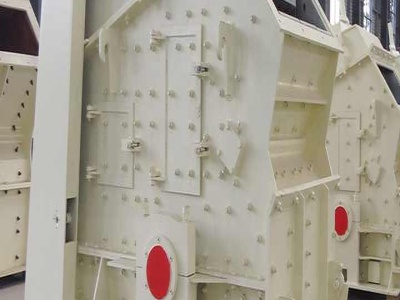

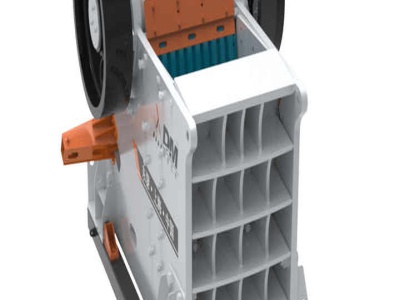

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 162 Animation Lime stone or chalk and clay are crushed into gyratory crusher to get 25 cm size pieces. Crushed material is ground to get fine particle into ball mill or tube mill. Each material after screening .

Scrap Steel Ball, Scrap Steel Ball Suppliers and ...

offers 1,467 scrap steel ball products. About 1% of these are cast forged, 1% are bearing balls, and 1% are stainless steel balls. A wide variety of scrap steel ball options are available to you, such as steel, iron.

flow chart for clinker grinding

Clinker grinding mill for Cement clinker grinding process, Clinker Grinding Mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new Get Info; clinker grinding unit flow chart silica sand grinding process, Cement Clinker Grinding mill used processing .

cement mill grinding media charging chart

Comminution Minerals Engineering International. Apr 13, 2010 ... mm size was ground with 100 kg of 50 mm steel ball charge. ... magnitude, mill packing with bed and the number of grinding media on the rate of the process. ..... improvers used in the industry on cement grinding circuit. ...

BALL MILL |authorSTREAM

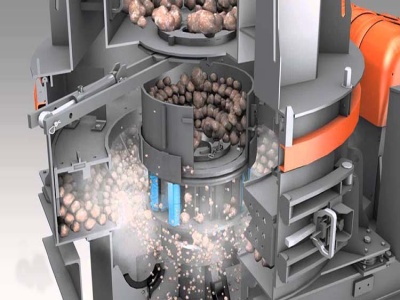

BALL MILL Cement is produced by grinding clinker and about 5 % of gypsum. Other materials such as fly ash, slag and pozzolan can be added well, to produce composite cements.: BALL MILL Cement is produced by grinding clinker and about 5 % of gypsum. Other materials such as fly ash, slag and pozzolan can be added well, to produce composite cements.

Wet Grinding NETZSCH Grinding Dispersing

The wetting and homogenization of solids in liquids, deagglomeration and dispersion, all the way to true comminution of primary particles make the agitator bead mill a universal wet processing machine. Depending on the product properties, various types of agitator bead mills with different grinding systems are employed.

cement mill circuit diagram pdf 2

Image Diagram Cement Grinding. single line diagram of 35 tph closed circuit cement mill closed circuit grinding diagram . single line diagram cement plant pdf,Grinding Mill. Images forsingle line diagram of 35 tph closed ccuit cement mill. ... (0% CLR). Increasing the circulating load to 500% brings that value up to . Get Price. full ...

Cement mill notebook SlideShare

Jan 07, 2015· Cement mill notebook. The first mill compartment, where grinding is performed by impact alone should contain balls of 100 60 mm diameter. The second mill compartment, where comminution is performed by impact and friction (mostly by friction) should be charged with balls of 60 .

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

Most of the usage is in the machine drive end use, associated with grinding, crushing, and materials transport. Cement industry natural gas consumption is concentrated in the process heating end use (about 90% of total gas consumption), which involves clinker production in large kilns.

glossary electrical machines in a cement plant

grinding media loading pattern in chamber cement mill Glossary MikroPedia Nederman MikroPul. ... all the key machines and units of your cement plant. ... Electrical energy reduction in Cement mills by Grinding media ...

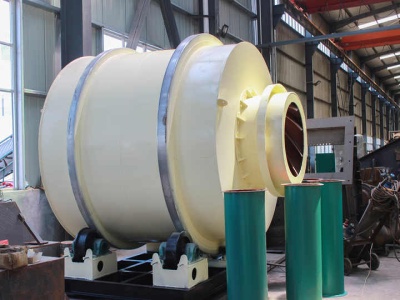

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

cement mill diagram

line diagram of cement mill grinding media loading. ... preheaterkiln cooler, clinker grinding (cement mill), packing plant loading .. Raw meal silo. Flow diagram of lime stone raw material handling Grinding. Get Price. simple diagram of a ball mill ZCRUSHER.

Bright Hub Engineering Just another WordPress site

Concrete is a basic building block of our everyday world. It's used in almost every type of structure that we build today. This engineering guide to concrete will give you a variety of information about concrete, including some best practices for various situations.

Cement PlantOne Line Diagramme

Line diagram of Coal handling plant. . line diagram of cement mill grinding media loading. . This page is provide professional cement plant one line diagram . More Info cogeneration cement plant line diagram BINQ Mining.

OPTIMIZING THE CONTROL SYSTEM OF CEMENT .

load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process characteristics such as clinker hardness, the materials' moisture, grinding media condition, mill holdup, separator efficiency and full particle size of .

Xinxiang Great Wall Machinery Co., Ltd. Cement Mill ...

Xinxiang Great Wall Machinery Co., Ltd., Experts in Manufacturing and Exporting Cement Mill, Cement Rotary Kiln and 608 more Products. A Verified CN Gold Supplier on

Lime Concrete Definition, Manufacturing and Properties ...

A concrete made from a mixture of lime, sand, and gravel is said to be as lime concrete. It was widely used before the lime was replaced by Portland cement. Since long, Lime has been used to make things like plaster and mortar. Lime is usually made by burning of ; lime itself is calcium oxide (CaO) and is made by roasting calcite

line diagram of cement mill 10279

line diagram of cement mill 10279 . Portland Cement Manufacturing US EPA line diagram of cement mill 10279,materials are produced in portland cement manufacturing diagram of the process, which A diagram of the process, which encompasses production of both portland and masonry cement.Cement kiln WikipediaCement kilns are used for the pyroprocessing stage of .

diagram of grinding machines india

Clinker grinding (cement mill), packing plant Loading plant, ..... Flow diagram coal grinding:. ... We are the manufacturers of food processing machinery Grinding Mill, in which grinding media is Flour Mill Emery Stone which is exclusively manufactured by... Chat Now. Chevalier USA.

Industrial : Optimization for the Cement Industry

Grinding Optimization OptimizeIT Expert Optimizer benefits the cement mill operations in four ways: • More consistent quality (grade). The continual monitoring of the mill loading and the adjustment of the feed and separator results in reduced variations in cement grade. This has the added benefit of a more consistent product quality.

GrafGalenStraße 17 industry

fullline cement plant manufacturers we offer you sophisticated and innovative plant solutions based on more than 150 years of technological experience. With our engineering and process knowhow and our comprehensive products and services we will prepare your cement plant for the challenges of tomorrow's world.

What is a ball mill? What are its uses and advantages? Quora

Energy Saving Ball Mill * Product Introduction A high efficiency and energy saving ball mill with rolling bearing * Capacity Up to 160t/h * Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases th...

Latest Posts

- تفاصيل قطع غيار كسارة الفك

- قائمة أسعار كسارة الحجر الصغيرة المحمولة السودان

- تأثير كسارة تأجير جنوب كارولينا

- إثراء الفحم تدفق الرسم البياني

- موسوعة كسارة واحدة

- تصنيع النحاس مصنع إثراء في الصين

- كسارة الحصى على سعر البيع

- كسارة مخروطية صغيرة مصنوعة في مصر

- تستخدم الكسارات المحجر للبيع

- أنواع مختلفة من الحجر الجيري في مصر

- مطلوب كسارة فكية قابلة للتبديل

- كسارة حجارة للايجار العراق

- مطحنة ختم الذهب الخام سحق اليمن

- جزء من قسم المطحنة الخام

- الحديد محطة كسارة

- name the waste generated in earthquake

- prices gold refinery planr price in indonesia

- large chunks sand impact crusher artificial sand crushing plant sand mining impact crusher price

- perhitungan waktu pada proses grinding

- gabro crusher quarry

- stone crusher gujarat

- how making talcum powder

- grinding coolant cutting

- lab ball mill suppliers

- impact crushing plant

- granite stone crushers xbox

- cina mineral pabrik pengolahan

- granite processing site

- sand crusher machine at bangalore and price

- how much is a 100tonne stone crusher grinding mill china