milling and grinding pdf

Milling Tools Inserts

• Universal modular milling cutter for face milling of steels, stainless and cast iron materials • Exclusive TWINCUT insert design offers round, 8, and 12 cutting edges for high production milling applications • Cartridge design interchangeable with other LMT MultiMills • Available in coarse and fine pitch See page 8 for Inserts.

Jig Grinding, EDM or HighSpeed Milling? : MoldMaking ...

Jan 01, 2007· Jig Grinding, EDM or HighSpeed Milling? ... highspeed milling is being compared to jig grinding as an alternative process. As in the past, the complaints associated with the costs of jig grinding—centered on capital equipment costs and labor issues—forged the way for the new hard milling process into the world of mold manufacturer ...

Difference Between Up Milling and Down Milling mech4study

Mar 04, 2016· The milling process is done by the machine, which hold bot the tool and work piece in jig and fixture, known as milling machine. There are two ways to cut the material from the work piece through milling machine. First one is named as conventional milling or Up milling and the other one known as climb milling or down milling.

S2 – FiveAxis Dry and Wet Machining | vhf

S2 is our most versatile fiveaxis dental milling machines. It has a blank changer for 8 blanks and is designed for dry machining as well as for wet machining.

A treatise on milling and milling machines .. : Cincinnati ...

A treatise on milling and milling machines .. by Cincinnati Milling Machine Company. Publication date c1916 Topics Millingmachines Publisher Cincinnati, Ohio, Cincinnati milling machine company Collection cdl; americana Digitizing sponsor MSN Contributor University of California Libraries Language ... PDF download. download 1 file ...

Grinding (Machining) an overview | ScienceDirect Topics

Grinding is a machining process which uses hard abrasive particles for cutting, where the surface speed of the abrasive tool (namely the grinding wheel) is relatively faster compared to other machining processes such as turning and milling. Technically, grinding is a subset of cutting where each grain of abrasive functions as a microscopic ...

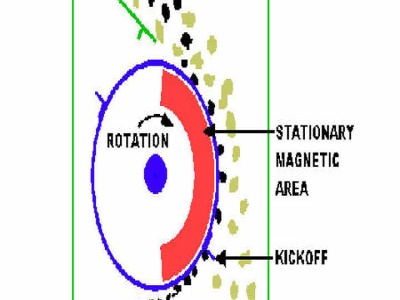

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

a unique patented design concept that includes a new grinding tank internal configuration and side discharge screen which allows mills to run at higher speed, using smaller media, and continuously discharges products out of the mill by centrifugal force. (Fig. 6) HSA Attritors generally operate from RPM using grinding beads from 13mm.

2009 GetsNimbler

classifiers or screeners to form a closed grinding process loop (Figure 5). By continuously classifying out fines and returning oversize material to the mill, such systems can very efficiently provide sharp particlesizedistribution grinds. As a rule of thumb, dry grinding generally will .

Dry Milling an overview | ScienceDirect Topics

Dry milling is often used to describe three different processes when talking of maize. The first process, stone grinding, is the oldest and is also known as whole kernel dry milling or full fat dry milling. Whole kernel dry milling does not seek to fractionate the maize kernel but to grind it into uniform size particles, usually flour or meal.

Machining Molybdenum

in finishing applications. The benefit of using lubricants during moly machining is to avoid wear and tear on the tools, but avoid using the lubricants with electronic applications. Chlorinated oils are ideal for a machining lubricant, as molybdenum tends to chip when being machined. Use plenty of coolant, and avoid facemilling, if possible.

Milling Machines Engineering

Milling Machines A milling machine is a power driven machine that cuts by means of a multitooth rotating cutter. The mill is constructed in such a manner that the fixed workpiece is fed into the rotating cutter. Varieties of cutters and holding devices allow a wide rage of cutting possibilities.

NETZSCH Grinding Dispersing

News The World of DryGrinding and Classifying through the Eyes of Experts NETZSCH at the Anuga FoodTec 2018 Fine Impact Mill ~Condux 60 – Smallest, complete Grinding Plant The Best of Both Worlds SMARTREMOVAL has revolutionized filter hose changing

ENERGY SAVINGS AND TECHNOLOGY COMPARISON .

A regrind ball mill with a mix of small grinding media can be as energy effi cient as an Isa Mill charged with and mm beads. In vertical stirred mills, energy savings vary from 30 per cent to 60 per cent. To carry out the same fi nal grind, a vertical

Chapter 9 MILLINGGRINDINGDRILLING AND SLOTTING ...

The millinggrindingdrilling and slotting attachment is commonly referred to as a Versa Mil. It is a compact, portable unit capable of doing many machining operations th at normally require expensive single purpose machines. With the different attachments that are available with the unit, drilling, shaping, milling, and grinding can be ...

MACHINING GRAPHITE AND CARBON

Grinding graphite and carbon . Milling graphite and carbon Tools: grinding wheel with the structure parameter between 6 to 9 . Parameter Value in metric unit Value in US unit General purpose (made by silicon carbide wheels of grit 2046) Cutting speed . 2030 m/s 65100 ft/s .

MANUFACTURING PROCESSES – II

The milling attachment is mounted on the saddle of the lathe. Thread milling is of two types; Fig. Thread milling by attachment in centre lathes. ο Long thread milling Long and large diameter screws like machine lead screws are reasonably accurately made by using a large disc type form milling cutter as shown in Fig.

Hardinge Turning, Milling, Grinding Workholding

As the only machine tool OEM provider offering turning, milling, grinding, workholding and custom manufacturing solutions, Hardinge is ideally positioned to provide you with an innovative, costeffective custom solutions that meets your needs. Learn More

MAIZE MILLING BUSINESS PLAN SAMPLE iMvubu .

MAIZE MILLING BUSINESS PLAN SAMPLE iMvubu Holdings, Ltd Siavonga District Zambia. 1. Executive Summary 1. Executive Summary a) Business Concept iMvubu Holdings, Ltd is proposing a maize mill to service the remote Siavonga district of Zambia. iMvubu will buy maize and produce maize meal with bran as a byproduct.

Optimization and Control of a Primary SAG Mill Using Real ...

1 Optimization and Control of a Primary SAG Mill Using Realtime Grind Measurement Steyn*, K Keet**, W Breytenbach*** *Control Engineer, Anglo American Platinum, Control and Instrumentation Department, Johannesburg,

(PDF) DESIGN AND OPERATION OF VERTIMILL® FOR SECONDARY ...

PDF | A silver/lead/zinc mine in Queensland, Australia was originally designed to treat million wet metric tonnes per annum. The original grinding circuit consisted only of primary autogenous ...

Calculate and Select Ball Mill Ball Size for Optimum Grinding

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Latest Posts

- اقتصاديات غسيل الرمال مصر

- ميزانية جديدة للمكوس على مصانع الدرفلة

- تستخدم الذهب الخام المصنعة تأثير محطم مصر

- كسارة متنقلة دونيجال

- معدات السحق pdf

- أسعار خوذات التعدين فى مصر

- الحزام الناقل المعبئ الأساسي

- مصغرة مصنع صخرة محطم لعبة

- كسارة البازلت من ألمانيا

- مبدأ عمل مطحنة الكرة والحساب

- تكلفة انشاء الصغيرة محطة كسارة حجر

- كاولين كسارة متنقلة

- المعادن ومصانع التجهيز في العراق

- السرعة الحرجة المعادلة في تراجع طاحونة

- مركزية كربيد آلة طحن في

- crusher for quarry spec

- list of material for cement productions

- crushing grinding rock

- gold mining in ghana map

- aggregate crushing plant pakistan

- beneficio zircon sand machinery and equipment production

- peralatan daur ulang kaca

- hammer mill and accessories cost html

- jaw crusher lm53 3 3cs specifiions crusher mills cone crusher jaw

- mobile crushers with engine

- stone crusher militaryrock crushing

- sekoko waterberg coal mine

- crusher equipment paper

- by lows for crushing plant

- barite crushing ball mill price