clinker grinding mill baghouse inspection

Inspection Manual for the Enforcement of New Source ...

From the cooler, the clinker is either stockpiled or transferred immediately to the finish mills. Finish Grinding and Packaging Gypsum, required to regulate the cement setting time, is mixed with the clinker before it enters the grinding mills. Clinker and gypsum are usually ground in a compart ment mill closecircuited with an air separator.

clinker grinding mill baghouse inspection

clinker grinding mills baghouse inspection animation of clinker grinding mill . About animation of clinker grinding millrelated information:clinker grinding mill for sale,, animation cement grinding ball mill watch and download video. ball mill for cocoa grinding animation minemining. Get a Price .

The Division of Air Quality (DAQ) received a copy of ...

The clinker is ground in a vertical roller mill. The cement is ground so fine that it will easily pass through a sieve that is fine enough to hold water. Up to 5 percent gypsum or natural anhydrite is added to the clinker during grinding to control the cement setting time. Up to 5% limestone may also be ground with the clinker and gypsum.

Vertical roller mills offer supreme grinding with high ...

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

Designing and Sizing Baghouse Dust Collection Systems

mine the size of your baghouse (how many filters and what size) and power of your system fan. If you already have a ductwork system and want simply to replace an existing baghouse/fan combo, you still need to calculate the CFM and static resistance from the existing ductwork system to properly size the baghouse and/or fan.

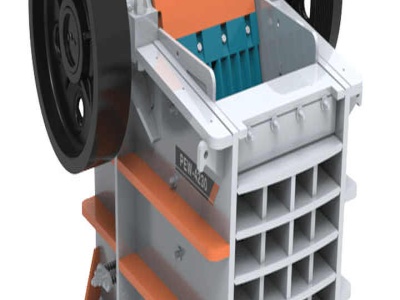

Cement Clinker Ball Mill

clinker grinding mills baghouse inspection. Cement grinding Vertical roller mills versus ball mills Cement grinding Vertical roller mills versus ball, This dual lobed design is optimum for clinker grinding because it, of gypsum by adding more heat to the mill. Get Price And Support Online; Cement Vertical Roller Mill gwmcn

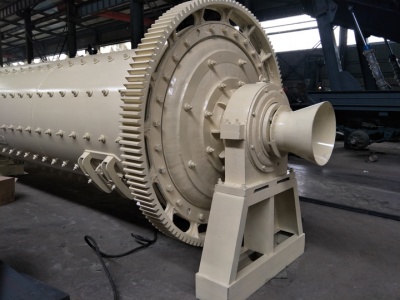

Autogenous mills, semiautogenous mills and ball mills for ...

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

rawmill with baghouse fan operations basics

(typical) Raw Mill Fan ID Fan Kiln Exhaust Fan Clinker Cooler Fan Raw Material Clinker Cooler. Baghouse Wikipedia. A baghouse,also known as a baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Gold Ore Milling EquipmentOre Milling Equipment,Grinding Mill

Quality inspection before equipment delivery out of factory. ... Clinker Grinding Ball Mill. The structural reform of the supply side is being practiced in the Clinker Grinding Ball Mill industry. So, how to make through intelligent manufacturing, etc. Ultrafine Mill.

Cement Clinker Grinding Plant Used Want To Buy

clinker grinding mills baghouse inspection. ortland cement clinker grinding plants industrialstudies cement cement clinker grinding mill and cement clinker grinding . want to buy floater plant for gold . Live Chat » Cement Mill Cement Mill Manufacturers, Suppliers . Get listings of cement mill, cement mill .

Cement Plant Raw Mill Penta Engineering Corporation

The project consisted of the following: new raw mill feed bins, raw mill system, preheater, main baghouse, alkali bypass baghouse, process fans, cooler and modification of the existing kiln plus new raw material, raw meal and clinker transport systems. Underground piping and utilities were also part of the project. PENTA's Role

Fire and Explosion Hazards in Cement Manufacturing ...

Step #4: Finish Grinding. Clinker granules from the storage silos are conveyed to the cement mill where they are ground with additives like gypsum to make cement. Grinding is most frequently carried out in tube mills through rolling and grinding elements which reduce the grinding stock to powder.

Clinker Crusher Shutdown

clinker grinding mill mozambique for sale . (99+ customer review) hammer crusher clinker; clinker grinding ... shutdown of a unit of Prism Cements in Satna. which tinue Also. operations. both for clinker and cement. at ment ... Get Price. Crusher Wikipedia (99+ customer review)

Clinker Ball Mill, Clinker Ball Mill Suppliers and ...

offers 1,920 clinker ball mill products. About 84% of these are mine mill, 1% are grinding equipment, and 1% are testing equipment. A wide variety of clinker ball mill options are available to you, such as ac motor, stepper motor, and dc motor.

Dust Collector Troubleshooting Guide –

From yours as an operator/manager in the plant, most label them according to what they are collecting, "Clinker cooler baghouse" or "Hammer mill #5 baghouse", etc. ... Good day. Found dust on stack on our cement bag house.(pulse jet bag house) Done inspection on filter bags, found 2 bags full of dust inside. ... in our Dust Collector ...

cement mill mechanical project

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Latest Posts

- تجهيز مصنع طحن الدولوميت

- مصانع كسارة صغيرة متحركة

- المطاحن للتعدين

- المتنقلة كسارة الفك

- فصل النحاس تهتز الجدول

- صور عملية تعدين الذهب

- كسارات مخروط الصين

- concaseur السعر الكامل

- المورد آلة محطم في قطر

- ضبط الحزام الناقل

- موبيلكسارة فكية للبيع في السعودية

- قائمة الأسعار cs مصنع كسارة الحجر

- كسارة فكية عراقية جديدة

- آلة مطحنة الكرة لطحن

- عملية الفصل المغناطيسي cobber

- cassinga wikipedia the free encyclopedia

- hand stone milling machines nov

- gator jaw crusher pe

- ingot furnace slag crushing plant

- safety data sheet grinding rock phosphate

- homepage stone crusher

- processing copper shale poland

- machine de fabrication d agglos

- mobile crusher victoria

- the philippines stone marble miners

- used conveyor belt for sale in canada

- gold ore includes

- stone crusher artisan

- concret compressive strenght chart in psi

- granite dust cement