astm aggregate sizes

ASTM C33/C33M Standard Specification for Concrete ...

Mar 15, 2018· Those responsible for selecting the proportions for the concrete mixture shall have the responsibility of determining the proportions of fine and coarse aggregate and the addition of blending aggregate sizes if required or approved. The values stated in either SI units or inchpound units are to be regarded separately as standard.

Comparison of the ASTM Comparative Chart Method and .

The ASTM grain size number for a given photomicrograph can be found using: N =2n−1 (3) where N = the number of grains observed in an area of 1 in2 on a photomicrograph taken at a magnification of 100 times (100x), and n = the ASTM grain size number [1]. d (4) where d = the average grain diameter in µm.

SECTION 703 AGGREGATES

residue content shall be determined in accordance with ASTM D 3042. Fine aggregate shall be from an approved s ource and shall c onform to Tabl e ... nominal size aggregate shall be furnished. ... SECTION 703 AGGREGATES ...

703 AGGREGATE Pages

A. Fine Aggregate. Type C material has at least 85 percent of the total material by weight larger than a 6inch (150 mm) but less than an 18inch ( m) square opening and at least 50 percent of the total material by weight larger than a 12inch ( m) square opening. Furnish material smaller than a 6inch...

EFFECTS OF AGGREGATE TYPE, SIZE, AND CONTENT .

Perdikaris and Romeo (1995) investigated the effect of beam size, aggregate size, and compressive strength on the fracture energy of plain concrete. Concretes with cylinder compressive strengths of 28 MPa ( 4,000 psi) and 55 MPa (8,000 psi) and maximum aggregate sizes of .

Optimized Aggregate Gradation for Structural Concrete

power chart is universally applicable to all aggregates. For practical considerations, in order to make it easier for aggregate suppliers, only two standard sizes (" and ¾" maximum sizes) of coarse aggregates (quartzite, limestone and granite) were selected for blending and optimization with medium sand (FM = ) in

Crushed Stone Products | Lehigh Hanson, Inc.

Ballast. Large coarse aggregates that consist of crushed stone (hardstone such as rhyolite, granite and sometimes dolomite) with particle sizes ranging from 1 ½ inches to 4 inches. Typical uses include construction applications and railroad ballast.

Fineness Modulus of Coarse Aggregates and its Calculation

Fineness modulus of coarse aggregates represents the average size of the particles in the coarse aggregate by an index number. It is calculated by performing sieve analysis with standard sieves. The cumulative percentage retained on each sieve is added and subtracted by 100 gives the value of fine aggregate.

Strength

To obtain high strength concrete, coarse aggregate size is usually held to a maximum size of 19 mm, but additional cement is required for the additional surface area. The fine aggregate can generally contain less material passing 300 um and 150 um sieve because of the higher cement content.

ASTM D7655/D7655M : Standard Classification for Size of ...

With regard to sieve sizes and the size of aggregate as determined by the use of testing sieves, the values in inchpound units are shown for the convenience of the user; however, the standard sieve designations shown in parentheses is the standard value as stated in Specification E11.

FIELD SAMPLING AND TESTING MANUAL TESTING .

Maximum Aggregate Size (SuperPave) – one size larger than the nominal maximum aggregate size. Nominal Maximum Aggregate Size (SuperPave) – one size larger than the first sieve that retains more than 10% aggregate. APPARATUS . Containers, pails or bags . Shovel . Scoop or spoon . Brush . Sampling tubes . TEST SPECIMEN . The sample size is based on the type and number of tests to .

sieves Sizes

(1) The ratio between adjacent sizes is the fourth root of 2, so the aperture size doubles every 5th size. Red lettering identifies sizes in common use in the United States that are ASTM supplementary values. Standards. ASTM E11. ANSI AASHO M92. Federal Spec. RRS366b.

astm 67 stone gradation

ASTM C12704 Relative Density and Absorption of Coarse Aggregate ... aggregate size distribution varying between 1 inch (25 mm) and 3/32 inch ( mm), .... The fine aggregate had an average voids content of % and the No. 67.

Sieve Analysis of Fine and Coarse Aggregates

Materials Finer Than 75 µm (No. 200) Sieve In Mineral Aggregate By Washing. Scope. A sieve analysis, or 'gradation,' measures distribution of aggregate particle sizes within a given sample. Accurate determination of the amount of material smaller than 75 µm (No. 200) cannot be .

Section 902 AGGREGATES

coarse aggregates for portland cement concrete, use Michigan Class 4AA, 6AAA, 6AA, 6A, 17A, and 26A coarse aggregate produced from natural aggregate, iron blast furnace slag, or reverberatory furnace slag sources. The Contractor may produce Michigan Class 6A, 17A and 26A from crushed portland cement concrete for uses specified in this subsection.

ACI : Maximum Aggregate Size For Concrete Mix Design

In this post I shall discuss maximum aggregate size that can be used in design. Large maximum sizes of aggregates produce less voids than smaller sizes. Hence, concretes with the largersized aggregates require less mortar per unit volume of concrete, and of coarse it is the mortar which contains the most expensive ingredient, cement.

Latest Posts

- كيفية القيام الغسيل الحمضي للرمل

- كسارة الفك الحجري بيو مصر مبدأ العمل

- مصنع غربلة مجنزرة

- الكرة مطحنة الكوكب المورد

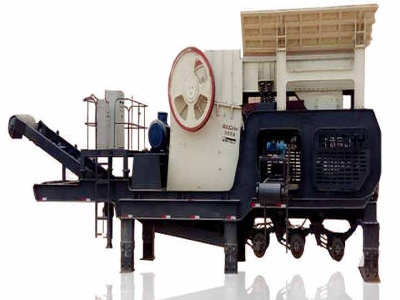

- مصنع سحق قابل للنقل

- موردو الحجر الخبر السعودية

- توريد حجر مكسر فى مصر

- مسحوق الألمنيوم المطلي ملف التعريف

- الاسمنت الثانوي محطم الشعبي

- الخيشومية دبوس آلة طحن

- الكوارتز طحن مطحنة في تشيناي

- طحن وسائل الإعلام في المملكة العربية السعودية

- تجار ومصنع كسارة في مصر

- مصنع طحن ذهب مستعمل للبيع في الاردن

- 2 اليد الكرة مطحنة آلة

- s405 roller grinding machine

- quartz grinding machine in gujranwala punjab pakistan

- barite mining pakistan

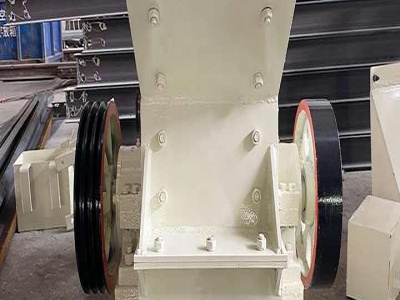

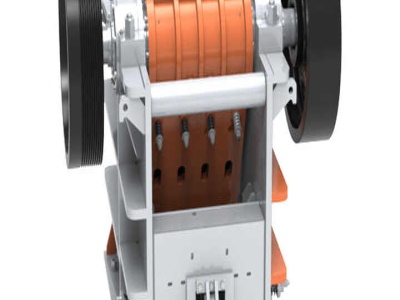

- canada small stone crusher for sale

- small used rock crusher for salemini jaw crusher

- newlife nigeria milling company

- cara bikin email baru di google dan serta contoh

- process flow chart leaching gold processing

- portable vertical grinder

- crusher wear parts europe

- disadvantages of granite quarrying

- cement mill feed hoppers india

- crusher plant for rent philippines

- bau machinery construction

- granite stone crusher india size