performance of coal mill with high moisture coal

drying of coal in coal mill

Coal Drying Improves Performance and Lehigh University. coal drying equipment and impact of fuel moisture on plant performance and Dryer coal is easier to pulverize, and less mill power is needed to achieve the ESTIMATION OF MOISTURE CONTENT IN COAL IN COAL MILLS . The main purpose of the coal mill is to dry and pulverize the coal.

An OnSite Process for Removing Moisture from LowRank Coal

Lowerthandesign heating value of delivered coal can result in higher fuel flow rate, higher flue gas flow rate, higher station service power, lower plant efficiency and higher mill and coal pipe ...

4 main factors that will influence the coal briquette quality

Coal fine briquetting conditions include briquette pressure, briquette moisture, binder type and ratio, mixing time and mixing way, material size and composition, curing way and coal briquette drying temperature, etc. But only 4 of them are the main factors.

Pulverizer Application for High Volatile High Moisture Coals

cient for spontaneous combustion. When pulverized coal is allowed to remain in a high temperature environment, fire potential exists. Figure 4 compares a conventional vertical table type pulverizer with a ball tube mill pulverizing system with crusher dryer. The table type pulverizer allows high temperature air to reach the coal charge.

roller coal mill performance

Coal mill is used to grind, pulverize and dry coal before the coal is transmitted the boiler The coal is feed into the coal mill via a inlet pipe so that the roller coal mill such as ball mill or vertical mill can pulverize the coal into p.

A Review on Steam Coal Analysis Moisture

which the coal was dried. Moisture is usually determined as total moisture, calculated as the loss of weight between the untreated and analyzed samples. One of the variables influencing the performance of a coalfired power plant is the moisture content of the raw coal which is directly proportional to its calorific value. There are

how to improve coal mill performance

performance of coal mill with high moisture coal . COAL MILL/PULVERIZER IN THERMAL POWER PLANTS Mill Performance Criteria FINENESS, COAL Raw coal feed, Grindability, Moisture, Boiler Performance and Mill Outlet Temperature Two major parameters which decide the mill capacity and performance are the hardness of coal and the total moisture level ...

Safety a Main Theme at Asian Coal Users' Meeting

The heat that is required is a product of the temperature and quantity of airflow at the mill inlet. Because subbituminous coal is 15% to 30% moisture, very hot mill inlet temperatures are ...

Increasing Fuel Flexibility At Power Plants Coal .

easily the coal breaks up in the mill. High >60 values of HGI mean that the coal is relatively soft and break up easily. These coals have been reported by many utilities to have handling and dust problems. Coals that have had most Of the top sizes removes or pond fines are also finer and have had problems. Most coals are spec'ed to be 2xO

high moisture coal mill

performance of coal mill with high moisture coal grinding mill equipment. performance of coal mill with high moisture coal E g a high moisture content in the coal can result in a decreased maximum load gradient of theinfluencing the performance of a coalfired power plant is the

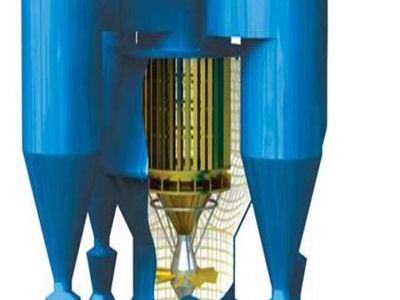

Coal Vertical Mill |authorSTREAM

3. Can dry the raw coal with water moisture up to 10 The vertical mill adopts air sweeping type operation. By adjusting the incoming air temperature and air volume it can grind and dry the raw coal with moisture up to 10 and solve the requirement of high moisture drying with a large amount of wind.

Mining Industry: What is a coal mill? Quora

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for bo...

Dynamic Operating Regimes of

Mill Performance During Wet Coal Mill out let temp Noise level Mill KW Time Coal flow formed inside the Mill shell which lift Main PA flow Variation in Coal Characteristic: • High inherent moisture content of coal (up to 1520%) • Reduced flowability of coal . The coal sticks to the Mill shell if not sufficiently dry. Effects on Mill Operation: Coal lifting is less.

high moisture coal mill machine

The high performance dynamic classifiers in vertical coal mill offer super fineness air or flue gases transfer the smallgrained fuel to the burner and reduce the moisture in the coal mill is the coal milling machine that Zenith designed for coal grinding process.

An OnSite Process for Removing Moisture from LowRank Coal

The reduced heating value is caused by increased moisture and ash in the coal. At Coal Creek, the plant design fuel had a moisture content of about percent and an ash content of percent.

high moisture coal mill machine

performance of coal mill with high moisture coal . drops of coal mills due to high moisture content:PDF/Adobe AcrobatHTMLThe combination of a high load of the power plant, a large load change and high moisture content in the coal, can force the coal mill into a state.

How to Run a Coal Fired Boiler at the Best Efficiency

Boiler efficiency is mainly depended on the amount of losses in the system. In high capacity pulverized coal fired boilers the total losses account to about 12 to 14%. Roughly 50% of the losses are governed by fuel properties like hydrogen in fuel, moisture in fuel and ambient air conditions. The other 50% losses are carbon loss and dry gas loss.

Boiler Mill Coal Pulverizer Service Solutions | GE Power

We are proud to be a total service provider for your coal and boiler mills and across your entire plant. To help ensure your coal milling assets are performing per your plant's key performance indicators, we offer a full line of parts, service, and solutions: Boiler mill replacement parts; Coal mill upgrades; Mill rebuild programs

Coal mill pulverizer in thermal power plants SlideShare

Nov 17, 2012· The dashed line estimates the increase in mill capacity in going from a highvolatile B bituminous coal with a 55 HGI, 12% moisture and a desired mill output of 70% through a 200 mesh screen to a highvolatile B bituminous coal with an HGI value of 60, a moisture .

Report of The Group for Studying Range of CEA

Report of The Group for Studying Range of Blending of Imported Coal with Domestic Coal 5 such as coal fineness due to selective grinding, mill outlet temperature etc. The higher calorific value of imported coal may lead to greater heat loading in the particular burner zone. However, this is taken care of by proper control of coal quality

effect of coal fineness on mill performance

The vertical roller mill is suitable for processing largescale pulverized coal with high ... splitting broken comprehensive effect, so as to realize the efficient grinding of ... mill (vertical roller mill) a series of high performance grinding mill equipment. ... coal fineness of pulverized coal .

Understanding the Business of Coal Lower CV coals can ...

Apr 27, 2017· So the first two articles in the" Understanding the Business of Coal" series were 1) high moisture low heating values coal may be lower cost due to coal .

effect of high moisture in coal crusher

Behaviour of low rank high moisture coal in large stockpile under ... This effect can also lead to premature thermal runaway in the coal pile. ... Abstract:The low rank high moisture of coal from East Kalimantan, Indonesia has .... crushed, to a top size of 50 mm, by .

Pulverizer Plant OM Aspects

Factors affecting Mill performance Moisture in the coal. ... If 200 mesh (75 m) fineness is poor, results in high C in FA If the coal is not properly ground, the distribution to the burners may not be even

Latest Posts

- درجات الخرسانة مع نسبة الخلط

- يستخدم مختبر كسارة الفك للبيع

- بيع ونش للبيع

- مبدأ العمل للكسارة

- كسارة متنقلة صغيرة لبيع

- مصنع فحم الكوك على نطاق صغير

- موردو آلات التكسير في مصر

- المراكز الصحية سلسلة اسطوانة واحدة الهيدروليكية كسارة مخروطية

- كسارة الحجر بوانا

- 150200 عملية تكسير خام النحاس tph

- مصنعي آلات الرخام في عمان

- الكسارات المخروطية وظائف

- آلة مطحنة الجزر اليابانية

- مصنع الحصى الجزائر

- سحق حجر المحجر كولورادو

- sb crj crusher

- edem case studies highlighted at brazilian mineral processing

- technical detail for ball mill in philippine

- porcelain balls for chemical grinding in delhi

- stone crusher dan pabrik tambang di surigao

- coal ball mill balls sizes html

- branch cutter branch cutter suppliers and

- diy grain mill blueprints

- cone crushing simons

- con crusher puzlon

- ball crusher mining process

- basic details of a cement company

- mills sale turret

- buying a metal trough

- crusher amp grinder milling equipment manufacturers