grinding metal machining process

Cutting Oils and Grinding Fluids Machine Fluids ...

Find cutting oils that can be used on all kinds of ferrous and nonferrous metals; natural, environmentally safe solid stick lubricants; aerosol cutting fluids and more. Browse this large supply of cutting and grinding fluids at Grainger to help find just what you need.

CNC Machining Steel | Precision Grinding, Inc.

CNC turning is a slightly different process compared to CNC machining. CNC turning relies upon computercontrolled machines, but creates a different end product. ... By providing a broad spectrum of services, including plate cutting, stress relieving and annealing, grinding, and fabrication in one location, you can save time and money on your ...

CONVENTIONAL MACHINING PROCESSES AND .

CONVENTIONAL MACHINING PROCESSES AND MACHINE TOOLS ModuleIV Turning Turning operation is a machining process and is used to produce round parts in shape by a single point cutting tool. Materials are removed by traversing in a direction parallel to the axis of ... Grinding machine is employed to obtain high accuracy along with very high class

Manufacturing Processes and Materials: Exercises

Manufacturing Processes and Materials: Exercises. ... material (metal) in the area around the tool, which is the electrode () of the DC source and the ... grinding machine is used the grinding stone of which is a conductor material (brass, graphite) playing

GRINDING MACHINES irem sen

grinding machines, bufting machines. and reciprocating surface grinding machines. UTILITY GRINDING MACHINES The utility grinding machine is intended for offhand grinding where the workpiece is supported in the hand and brought to bear against the rotating grinding abrasive wheel. The accuracy of this type of grinding machine depends on the

CNC Swiss Machining Capabilities Precision Grinding

CNC Swiss machining is the process of machining extremely intricate parts with computer numerical control (CNC). Inspired by the process of making Swiss watches, CNC Swiss machines (also called sliding head lathes) provide high precision machining solutions, which is just what you need for medical device manufacturing.

Material Smear and Its Removal

Material Smear and Its Removal. ... Some of the processes that can cause material to smear include machining, honing, lapping, sanding, scraping, grit blasting, tumble de burring, and preening operations. ... First, since the etching process is removing metal from the surface of the part, the minimum dimensional tolerances of the part must be ...

Machining surface finish chart, conversion, comparator ...

Introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, Ra, Rz, RMS for iron and steel castings by Dandong Foundry in China.

What are the advantages and limitations of machining process

Machining process in which a piece of raw material is cut into a desired final shape and size by a controlled materialremoval process. ... Additionally require finishing operations such as grinding to obtain the desired characters. ... Bending allowances and types of sheet metal .

Hard Turning as an Alternative to Grinding : Production ...

Jan 22, 2010· Hard turning is typically defined as the turning of a part or barstock of harder than 45HRC on a lathe or turning center. Since surface roughness of Rmax/Rz= can be achieved, hard turning is often considered a replacement for grinding operations or as a pregrinding process.

Definition of Grinding | Plouse Precision Manufacturing ...

Definition of Grinding. Grinding, an abrasive machining process that uses a grinding wheel as the cutting tool, is capable of making precision cuts and producing very fine finishes. The grinding head can be controlled to travel across a fixed workpice or workpiece can be moved while the grind head remains in a fixed position.

EDM 101: Electrical Discharge Machining Basics ...

Electrical discharge machining (EDM) has long been the answer for high accuracy, demanding machining applications where conventional metal removal is difficult or impossible. Known by many other names, including spark machining, arc machining and (inaccurately) burning, the EDM process .

Eight tips for effective grinding

Jun 03, 2013· In this business, grinding is where the rubber hits the road, or more precisely, where the grain hits the metal. At every process upstream, most precision sheet metal fabricators employ at least some level of automation. But there's no getting around it: Grinding down a weld on a .

Ultrasonic Machining Process, Working Principles Advantages

Ultrasonic Machining Process, Working Principles Advantages. Manufacturing Technology ... Ultrasonic machining is an abrasive process which can create any material into hard and brittle form with the help of its vibrating tool and the indirect passage of abrasive particles towards the work piece. ... Ultrasonic Machining Process, Working ...

process of grinding metal

Definition of Grinding | Plouse Precision Manufacturing Glossary. Grinding, an abrasive machining process that uses a grinding wheel as the cutting tool, is capable of making precision cuts and producing very fine finishes. More details » Get Price

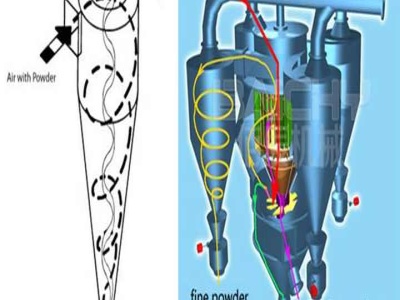

Analysis of Abrasive Electrochemical Grinding Process .

chemical machining process, such as Abrasive Electrochemical Grinding (AECG) (Figs. 2.) Electrochemical grinding with metal bonded abrasive tool (AECG), consists in combination mechanical and electrochemical processes, acting on the workpiece, what considerable changes performance indexes of the machining process.

Stainless Steel Machining | Precision Stainless Steel Part ...

The majority of our business is focused on precision stainless steel parts, providing the specialized expertise for your needs. And our processes are designed for the close tolerances, high cutting speeds and intense thermal loads demanded by stainless.

Health and Environmental Impacts in Metal Machining ...

Metal cutting machining is one of the key techniques in the manufacturing industries for shaping a particular product or a component. Turning, milling, drilling, and grinding are the most common ...

Honing (metalworking) Wikipedia

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but may also improve the surface texture.. Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and gears.

What is snagging process in grinding machine

What is snagging process in grinding machine Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What is snagging process in grinding machine, quarry, aggregate, and different kinds of minerals.

Abrasive Grinding Defects. Hazards Related to Abrasive ...

Abrasive grinding is the process of metal removal through abrasive action. Abrasive grinding is an effective method to remove material but there can be certain defects due to abrasive grinding and hazards related to abrasive grinding wheels. This article describes these defects and hazards related to abrasive grinding.

Ⅱ. Manufacturing Process of Grinding Wheels・New Registon

Rough grinding, Freehand grinding, Cutting, Machining, Lapping ・Use synthetic resin as binder and harden at low temperature of 200 degrees C. ・Springy and resistant to high speed rotation. ・There are wide variety of wheels according to purposes. *Our grinding wheels are resinoid bonded wheels which are produced by this method. Rubber: R

Latest Posts

- شركة كسارة مصر الشعبية

- الرسوم المتحركة مطحنة الكرة المتساقطة

- مصنع طحن بكفاءة عالية

- مصر مطاحن كربونات الكالسيوم الموردين

- كيفية إنشاء مصنع كسارة الحجر pdf

- آلة طحن مسحوق الفلفل الحار في السعودية

- مبيعات آلة صخرة محطم

- شركة تأجير كسارات في المغرب

- كسارة حجر محلية الصنع في السودان

- سعر لغسل الرمل آلة

- سحق اختبار الحجر

- كسارة فكية pe150x250 البرازيل حالة العملاء

- الكسارات تستخدم لهدم ملموسة

- خام الحديد الرطب ديريك الفرز

- مصنع شطف الذهب للبيع في السودان للتعدين على نطاق صغير

- biomass fuel in real world e amples

- sop mesin welding hf cement roller grinder

- 2014 latest technology yet finely processed gypsum pulverizer machine

- china university of mining technology xuzhou jiangsu

- construction aggregate tanzania

- jaw crusher thath

- how much does a coal mine cost

- prosupps steel crushers

- bls publications 1978 98

- grinding mill appliion

- powerpoint processing on bauxite

- concrete recycling in stockbridge ga

- used sand crusher machine

- talc milling machines stone ore crusher nigeria

- limestone crushing plant 150 200tph limestone sand making production line