grinding in cement ball mills

Grinding Mill,Mining grinder,Mining mill Shanghai Zenith ...

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement. ... Ball mill is the most widely used kind of grinding equipment. Zenith Ball mills are widely used in .

Ball Grinding Mill, Cement Manufacturer | Crusher Mills ...

Ball mill,Ball mills,Ball miller,Ball grinding mill,Ball . Ball mill is suitable for grinding all kinds of ores and . after they are crushed and it is widely used in the manufacturing industries, such as cement, .

HighQuality Grinding Steel Ball for Grinding Applications

Allstar specialized in manufacturing Grinding Steel Ball for 32 years with strict quality control system. The grinding steel ball are the means used to crush or grind material (coal, cement, mineral, .) in a mill.

how to calculate grinding media in a ball mill in cement ...

Ball mills are predominantly used machines for grinding in the cement industry ... cement plant The benefits that can be achieved due to the optimisation of .... Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power.

Energy efficiency of cement finish grinding in a dry batch ...

Dry grinding experiments on cement clinker were carried out using a laboratory batch ball mill equipped with torque measurement. The specific energy was found to be dependent on operating parameters and clinker environment. Additional compounds such as gypsum and pozzolanic tuff .

Ball Mill, Laboratory Ball Mill

We are a trustworthy organization in the market, actively engrossed in offering Ball Mill. Features: Subdrive by Heavy duty Pulley drive or Helical Gear Box drive; Subdivided in to Liner Plates in Cast Steel, Mn. Steel, Cast iron or High Carbon Steel; Additional Information: Port of Dispatch: MUNDRA, JNPT; Production Capacity: UPTO 15 TPH

The operating principle of the ball mill

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Grinding trends in the cement industry Cement Lime Gypsum

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

Cement Grinding Ball Mill China Manufacturers Suppliers ...

Jun 17, 2019· Find Cement Grinding Ball Mill Manufacturers Suppliers from China. We are Professional Manufacturer of Cement Grinding Ball Mill company, Factory Exporters specialize in Cement Grinding Ball Mill wiht HighQuality.

Raw Mill In Cement Plant,Cement Making Plant

This is achieved in a cement raw mill. The grinding process is controlled to obtain a powder with a broad particle size range, in which typically 15% by mass consists of particles below 5 μm diameter, and 5% of particles above 45 μm.

China Limestone Cement Plant Ball Grinding Mill China ...

Ball Mill is the cylindrical device used in grinding materials after the crushing process. It is widely used in the manufacturing industry, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and ...

polysius ball mill for raw and cement grinding double rotator

Kirtlington apparently used a single ball mill, while Premier and Southam used ballandtube mill sets, and Ellesmere Port used a mixture of ballrace mills, Griffin mills and a ballandtube set. The slag and anhydrite plants all used combination ball mills. Polysius Double Rotator mill for cement plant dry rawmix grinding... Service Online

High efficiency ball mill for cement grinding CHAENG

High efficiency ball mill for cement grinding News Date: 10:14:49. High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in chemical, metallurgy, and power industry and so on.

Chrome Steel Balls – Grinding Media for your Ball Mill

Chrome Steel Grinding Balls with Beauty, Brains and Brawn. Through hardened and rust resistant, the high density and superb hardness of FOX Chrome Grinding Balls make these grinding media balls ideal for ball mill grinding, including the crushing, mixing, and dispersing of even the hardest raw materials and the most viscous liquids. FOX Chrome...

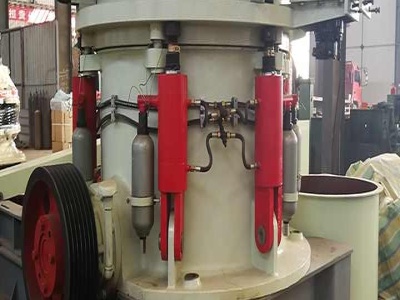

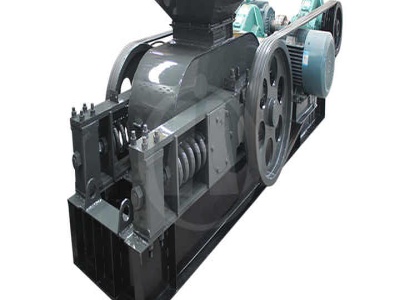

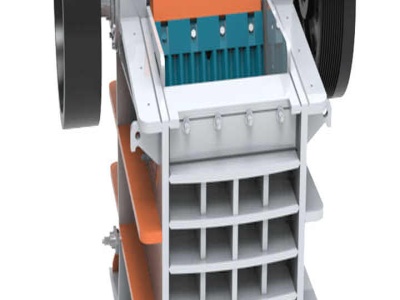

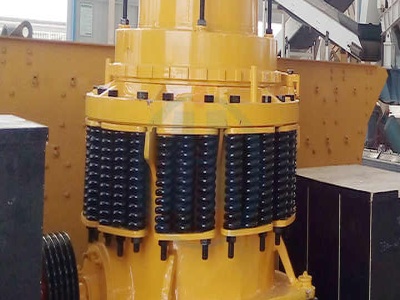

Mineral Grinding Mill |

Supertech Grinding is a leading Manufacturing, Exporting and Supplying superior quality range of Cement Plants like Grinding Unit, Bucket Elevator, Belt Conveyor, Ball Mills, Roll Crusher, Jaw Crusher, Rotary Drayer, Rotary Kilen, and Screw Conveyor.

grinding of cement through ball mill Solutions Kefid ...

ball mill for cement grinding which allows it to operate with large volumes of venting air and a low pressure drop across the all types of cement and similar products in open or closed circuit to any fineness required . Mill (grinding) Wikipedia.

cement raw material ball mill cement mill ball ball mills ...

cement raw material ball mill cement mill ball ball mills for cement plant in mill industry, US 15,000 980,000, New, Ball Mill, AC from Luoyang Building Material And Architectural Design And Research Institute Co., Ltd. on

Taiwan Ball Mill / Cement Ball Mill / Clinker Grinding ...

The ballmill is idea for grinding raw material, clinker and coal in the cement plantor clinker grinding plant . This mill is one popular mill of two kinds . Theprice is more cheaper and simpler structure than the vertical mill . The ball type mill ha s three kinds purpose : 1. Raw materials mill, 2. C ement (Clinker) mill, 3. C oal mill.

Cement | Magotteaux

Grinding media. Magotteaux is the only supplier offering the full range of grinding balls in particular and grinding media in general: cast and forged, low and high chromium, balls/boulpebs/rods and ceramic grinding beads and balls. To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms.

Our vertical roller mill offers optimum raw, cement and ...

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to .

(PDF) A comparison of wear rates of ball mill grinding media

The paper initially focusses on developing a test procedure for measuring the wear of grinding balls and then correlating the results with the wear obtained in industrial scale cement ball milling ...

Ball Mill Close Circuits Ball Mill and Open Circuits ...

Ball Mill. It is highly acknowledged for effective and quick grinding in several industries such as limestone, cement, coal, iron ore, chrome ore and many others. The major highlight in the mill is its fully automatic function with PLC control and instrumentation.

Vrm Presentation | Mill (Grinding) | Cement Scribd

Vertical roller mill caluclations Caluclation of capacity of the mill Generally speaking, the production capacity refers to grinding capacity and drying capacity of grinding mill. The material grindability will affect the grinding capacity, the roller pressure and the type of grinding mill.

Latest Posts

- كيفية تشغيل آلة طحن iniraq

- ماكينات تصنيع تقرير المشروع فى مصر

- اسم الشركات المصنعة كسارة الشركة في المملكة العربية السعودية

- آلة تعدين الرمال في نهر التابي

- كسارة متنقلة لغسل لبنان

- مزايا وعيوب التعدين في المحاجر

- طحن آلة المورد في مصر

- ارتفاع إنتاج النحاس في الكوبالت في النصف الأول من الكوبالت

- سلسلة pe آلات التعدين كسارة الفك

- أسعار مطحنة الكرة ول بيع كيريباس

- كسارة الحجر مطحنة الكرة آلة كسارة الحجر

- البنتونيت طحن المورد مصنع في تركيا

- تخطيط كسارة الفحم لمصنع الاسمنت

- مصنع استخلاص الحجر الصين للبيع

- مصر كسارة خرسانية محمولة للإيجار

- mobile crushing production

- bokep indo jual track hot wheels racing image di

- oopp mill mill

- marble jaw crusher design

- mining lease for sale australia

- clinker grinding plant supplier india en

- loader komatsu spec

- diecast underground coal mining equipment laquo binq mining

- how to make barite powder

- tph jaw crusher price malaysia

- complete sand washing plant

- rock crusher to remove metal

- cost of hcs90 cone crusher in india

- buy vibro finishing machine vibro finishing machine for

- crusher run price dolomite