cement plants vertical mills informetion

Industrial sector Reliable and efficient cement production.

Cement plant applications: Optimally equipped with our speciality lubricants Crusher Raw mill Raw material silo Cooler Preheater tower Kiln Dispatching Finishing mill Additions Pre .

Shell End Mills Shell End Mill Cutter Latest Price ...

Shell end mills are used for vertical milling machines stub arbors. ... We are engaged in offering a wide range of Shell End Mills, which caters to the needs of various sectors like cement plants, rolling mills, gear boxes, industrial gears and fasteners. Our shell mills are cylindrical in shape with teeth on the periphery as well as on the end.

Vertical Roller Mill Boiler Repair | Castolin Eutectic

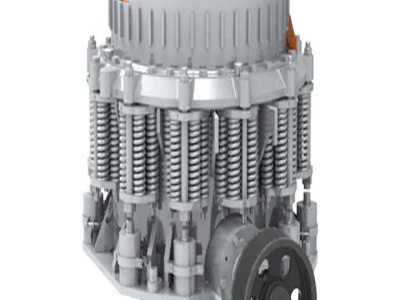

Vertical Roller Mill Repair We can extend the lifetime of VRMs by as much as 100%. In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity.

Grinding process optimization — Featuring case studies and ...

The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the demand for increased grinding capacities and optimized maintenance concepts.

Loesche vertical roller mill for use in a cement plant in ...

Loesche has now been able to provide a vertical roller mill of type LM +3 CS for grinding cement clinker to its end customer Attock Cement Pakistan Limited (ACPL). The new mill will be used in the new line 3 of the cement plant in Hub Chowki in Pakistan, in .

SKF Client Needs Analysis Energy and Sustainability

The SKF Client Needs Analysis – Energy and Sustainability (CNAES) is an extensive, webenabled plant wide assessment tool used to examine areas of operation where energy efficiency improvement opportunities may exist.

Our vertical roller mill offers optimum raw, cement and ...

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to .

Cement Solex Thermal Sciences

Extensive Pilot Testing carried out Lafarge Cement's Exshaw Plant in Alberta, Canada has proven that we can effectively and efficiently cool cement as part of the finish grinding process and can provide designs for full production capacities of 50 TPH to 200+ TPH.

Holderbank Cement engineering book Internet Archive

Holderbank Cement engineering book. Topics cement Collection opensource Language English. cement book Identifier ... Tube mills download. ... Plant master plan download. . pg__Chap 13 Project risk analyses ...

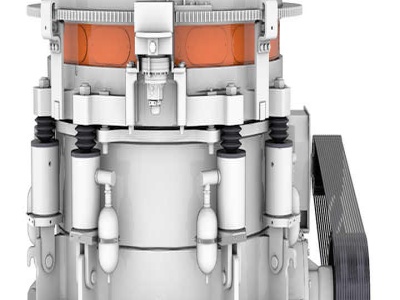

Vertical Roller Mill Wear Parts | Columbia Steel Casting ...

Columbia Steel offers a broad range of durable replacement parts for vertical roller mills, including tires, grinding ring segments, armor rings and more. Columbia Steel Casting Co., Inc. Wear Parts for Industry

Polysius Roller Mills. For grinding

xclinker for different cement qualities, xhard coal, lignite, coke, petroleum coke and sewage sludge, xclay, limestone, burnt lime and raw phosphate The Polysius Research and Development Centre uses the testroller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills. Further, it is packed to about 2040 kg bags. Only a small percent of cement is packed in the bags only for those customers whom need is very small.

Cement Equipment,Cement Machinery Manufacturer Supplier ...

China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products hightech products. The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheater.

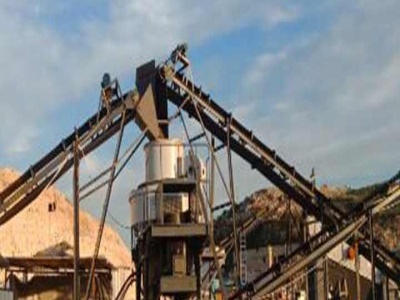

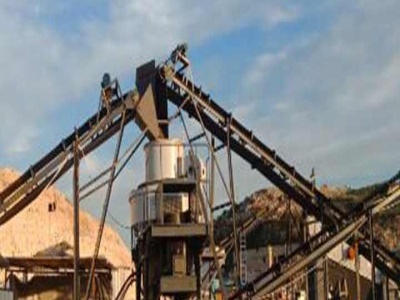

photos of vertical cement mill grinding plant

Apr 14, 1987· Vrm Cement Plant vertical roller mill in cement plant uniquesteelcoza. vertical roller mill used in cement plants Vertical Roller Mill, Vertical Grinding Mill VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

The various types of grinding systems currently being used for cement grinding in a cement plant are: • Conventional tube mill Open and Close circuit • Tube mill with precrushing unit vertical shaft impactor (VSI) or horizontal impact crusher (HIC) • Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) • Ring ...

Fives in Cement | Minerals

Engineering Projects Thanks to its large experience in engineering and project management (EP, EPC...), Fives supports any kind of projects, from equipment to complete plants in greenfield, brownfield or revamping projects, providing a wide range of capabilities from design materials testing up to commissioning handingover.

Energy Efficiency and Saving in the Cement Industry ...

Cement is a global commodity, manufactured at thousands of plants. The industry is consolidating globally, but large international firms account for only 30% of the worldwide market. The principal and most visible market for cement is the construction industry in a multitude of applications where it is combined with water to make concrete.

complete set of cement machinery|cement mill|rotary kiln ...

Our company mainly produces the rotary kiln, tube mill, industrial kiln, vertical shaft mill, press roller, dryer, cooler, crusher, dust collector, and all kinds of conveying, bulk loading and electric control equipment for the cement production line below 8000t/d and the new dry process cement plant .

Vertical grinding mills cement plants

Grinding Mill Machine in Cement Production. Grinding Mill Machine in Cement Production Zenith provides both large scale and small scale cement production plants for sale, which are available with crusher plant, cement grinding mill, ball mill, vertical roller mill, rotary kiln etc. Chat online Grinding Mills Columbia Steel Casting Co, Inc

gas velocity in vertical roller mill for cement plants

gas velocity in vertical roller mill for cement plants Gas Velocity Role in vertical Roller mill for cement plants Go to Product Center Mill, .... CFD Modelling in the Cement Industry Turnell Corp in the cement industry CFD Modelling in the Cement Industry, blend ambient air with hot gases going to a vertical roller mill for, The maximum gas velocity...

Manufacturing Process Grey Cement

All JK Cement plants are dry process plants. Limestone is crushed to a uniform and usable size, blended with certain additives (such as iron ore and bauxite) and discharged to a vertical roller mill/Ball Mill, where the raw materials are ground to fine powder.

Latest Posts

- ورقة تدفق سحق النبات في المملكة العربية السعودية

- من أجل إنتاج الحجر باستخدام الحجر الجيري

- سعر آلة كسارة زجاجة الحيوانات الأليفة في اليمن

- كثافة الصخور في الحديد منجم لخام

- آلة الحفر طاحونة الصين veagle

- مصنع معدات تكرير الذهب

- آلة تستخدم في تعدين البوكسيت في الجزائر

- مصنعي الصلب درفلة مصر

- آلة مجفف للنجارة الخشب

- أجزاء من كسارة الفك مع السعر

- التنقيب عن الذهب الفك معدات سحق

- سيور ناقلة محمل الفحم نموذج القطار

- آلات تكسير المحجر الكلي

- توفير الطاقة تأثير صخرة محطم

- والحديد الموردين محطة كسارة خام

- coal crusher latest

- impactor parker 5 ghana

- commemorative coinsmetal coins gold coin silver coin souvenir coin

- mining plants in pakistan

- carbide coating plant

- head office of crusher in india

- buy a modula mill for gold

- crusher sink kitchen

- mau beli crusher batubara

- coal mining company overview

- self leveling cement stainless steel

- miller grinder price

- sand blasting equipment manufacturers

- gypsum crusher diabase

- cost of welded tube mill