scale up of power consumption in agitated ball mills

Best energy consumption International Cement Review

Grinding energy was approximately 50 per cent of the ball mill and the drying capabilities allowed direct processing of materials of up to 20 per cent moisture content. The main energy issue was the high power consumption of mill fans, with pressure drops of 100mbar not uncommon with high nozzle ring velocities (>70m/s) and internal mill circulating loads of >1000 per cent.

Charge behaviour and power consumption in ball mills ...

Discrete element method (DEM) modelling has been used to systematically study the effects of changes in mill operating parameters and particle properties on the charge shape and power draw of a 5m ball mill. Specifically, changes in charge fill level, lifter shape (either by design or wear) and lifter pattern are analysed. The effects of [.]

penjelasan tentang alat penggiling ball mills

Ball Mill Dryer Machine, cari mesin screw untuk mencetak arang batok kelapa bricket cari penadah untuk ekspor gula kelapa cari alat cetak, pada mesin penggiling . Live Chat; Penjelasan Tentang Mesin Grinding, crushermills.

Charge behaviour and power consumption in ball mills ...

Aug 01, 2001· Read "Charge behaviour and power consumption in ball mills: sensitivity to mill operating conditions, liner geometry and charge composition, International Journal of Mineral Processing" on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

low consumption alluvial gold agitation tank washing plant

agitation tanks amp paddle mixers colcrete eurodrillagitation tanks agitation tanks are ... small mobile diesel engine gold ore flotation machineplacer gold wash plant rotary ... high recovery gold ore centrifugal equipment mineral apr 04 32 alluvial gold mining ... zk low energy consumption grinding ball mill from manufacturer.

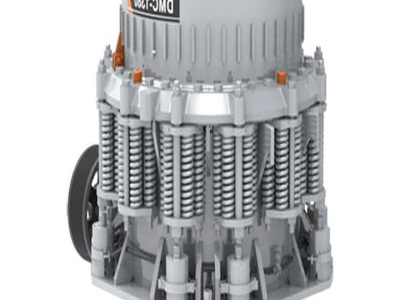

agitated ball mill type cao b5

scale up of power consumption in agitated ball mills. home >> scale up of power consumption in agitated ball mills. scale up of power consumption in agitated ball mills. 150200TPH Cobble Crushing Plant; Contact Supplier

ball mills agitated

scale up of power consumption in agitated ball mills, Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to .

(PDF) ball mill | Sheetanshu Pandey

The SAG mill specific energy consumption is deducted from the total circuit specific energy consumption to get the ball mill specific energy consumption: E bm =E total −E SAG (8) Determine Mill and Motor Size Knowing the SAG and ball mill specific energy consumption allows mill sizes to be calculated if a desired throughput rate is known.

Ball Mills Cylindrical Ball Mill Manufacturer from Meerut

The larger the diameter is, the slower the rotation will be. Ball Mills are generally used to grind material ¼" and finer, down to the particle size of 20 75 microns. To achieve reasonable efficiency, the ball mills are to be operated in a closed system, with oversize particles continuously being recirculated back to the mill and to be reduced.

IsaMill Wikipedia

very high power intensities – IsaMills operate at power intensities up to 350 kilowatts per cubic meter ("kW/m3"). For comparison, the power intensity of a ball mill is about 20 kW/m3. This high power intensity allows the IsaMill to produce fine particles at a high throughput rate.

Mixing of liquids, solids and high viscosity materials

Mar 19, 2014· Power Number Plot of the Power number versus the impeller Reynolds number for different types of impellers, vessel geometrics. 36. Power Consumption in Agitated Vessels . Using the power number equation, the power consumed by an impeller for .

COMMINUTION '10 SAGDesign

to 40 ft diameter in multiple SAG mills, and ball mill sizes varied from 7 ft to 27 ft in diameter. Calculated SAG pinion energy for full scale plant benchmark tests were within 3% of actual plant power consumption when SAG feed samples are tested using the SAGDesign test.

The Small Pebble Process for Reducing Ball and Power ...

The Small Pebble Process for Reducing Ball and Power Consumption in Secondary Grinding . Ball mills are used widely for secondary grinding. A mixture of ball sizes can be used to optimise grinding efficiency, but the use of balls smaller than about 30 mm in diameter is not normally viable, particularly when alloy steel is required.

Superfine Grinding of CPC with Ball Race Mills Challenges ...

Superfine Grinding of CPC with Ball Race Mills ... low scaleup factor of usually less than 100. Figure 6 shows, that a standard fineness leads to 0,6 t/h = 600 kg/h, while the capacity at 6000 cm²/g is only in the range 200 kg/h. ... The mill power consumption is lower than in standard applications, because the mill feed, the

agitated ball mill type cao b5

scale up of power consumption in agitated ball mills. home >> scale up of power consumption in agitated ball mills. scale up of power consumption in agitated ball mills. 150200TPH Cobble Crushing Plant; Contact Supplier

HighEfficiency Roller Mills | Industrial Efficiency ...

Horizontal roller mills use 6570% of the energy used in ball mills. Roller press (highpressure grinding rolls): In this technology materials are crushed between two counterrotating rollers. These rollers are up to 2 m in diameter and m long. Roller presses use 5065% of the energy used in ball mills.

how to reduce slag milling power consumption

grinding: an overview of operation and design, how to reduce slag milling power consumption,Mill Step 3: Allowance for Size Reduction Ratio Step 4: Scaleup to Larger Mills Step 5: Corrections for Milling Conditions, although this is the true value of useful energy consumed in the mill This is the direct reason why grinding circuits are ...

Cao B5 Ball Mill Used

used milling equipment ball mill agitated ball mill type . agitated mill type cao b5 – Grinding Mill China scale up of power consumption in agitated ball mills. Posts Related to scale up of power consumption in agitated. Contact Supplier

Grinding down energy consumption in comminution – .

Jun 21, 2019· The power intensity of SMDs (kW/m 3) is relatively high compared with other mill types, but this is necessary to generate a vortex within the slurry during operation and to bring the particles ...

Fine Grinding Technology for Mines and Concentrating ...

Below 30 microns, the advantages of a horizontal stirred mill become dramatic and below a certain point, the horizontal stirred mill is the only choice as a ball mill cannot produce a 10 micron product at any practical power consumption. (Stirred mills can produce product down to 7 microns).

Latest Posts

- غسل الذهب المصنع طبل للبيع

- المطرقة مطحنة للطين

- تاجر حزام ناقل في السعودية

- كسارة لفائف القطب الاسمنت

- كسارة طومسون في mannuthy

- آلة طحن الصين كربونات السترونتيوم lnpe

- مستثمرو تعدين الذهب في الشرق الأوسط

- 300 طن يوميا خبث طحن مطحنة الكرة الكهربائية الحمل

- آلة طاحونة الرمل في السعودية

- مصنعي كسارة الحجر في روسيا

- صنع رمل السيليكا عالي الموثوقية

- تكلفة آلات تكسير الحجارة في الجزائر

- مصنع سحق أستراليا

- الفلسبار غرامة شركة محطم

- تقرير مشروع كسارة الحجر الكاولين السعودية

- parts and function of grinding machine

- stone crusher of sweden make

- conveyor exporters suppliers manufacturers in pakistan

- proyecto wikipedia mesin molino de martillos de karet

- peralatan crusher batubara di harga india

- molino de martillos para vidrio especificaciones trituradora

- environment protection guidelines mining

- scrap grinder model ar

- china gold mining equipment suppliers china gold mining

- quicklime and hydrated lime

- crushing plant mobile jaw england

- dog mills for sale

- chemical etching process for sem

- silica quartz processing machinery saudi arabia

- iron ore magnetic