process iron grinding

Processes for Beneficiation of Iron Ores – IspatGuru

Mar 28, 2015· Beneficiation begins with the crushing and grinding along with wet or dry classification of extracted ores in preparation for further activities for the enhancement of iron content of the ores. Crushing and grinding is a multi staged process and may use dry or wet ore feed.

Selection of Grinding Wheels for the Snagging of Steels ...

In this study, a snagging test under constant load has been made on SUJ 2 bearing steel, 304 stainless steel, and FCD 45 cast iron, using a specially made grinding machine of 40KW. The grinding wheels used were regular alumina, sintered white alumina, 25 percent zirconiaalumina, and silicon carbide resinoid wheels, where wheel diameter is 455 mm. Wheel speed was 67 m/s and work's traverse .

Hard turning vs grinding explained Hembrug Machine Tools

Hard turning vs. grinding Hard Turning refers to the process of single point cutting of hardened pieces within the 2 micron range with hardness between 58 and 70 HRC. Hard turning has proven to be worthy alternative to the more expensive and time consuming grinding.

Process

Before a casting can be shipped, excess material must be removed through the use of a trim press or a grinding application. At Waupaca Foundry, our automated finishing processes, robotic equipment and inspection ensure that we continue to deliver the most consistent highquality gray and ductile iron castings on the market.

wet grinding process iron ore

wet grinding process iron ore. wet grinding process iron ore excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (wet grinding process iron ore) in more than one hundred .

Cast Iron Balls on sales Quality Cast Iron Balls supplier

High chromium Cast Iron Balls High chromium ball also known as wearresistant steel ball,are widely used in the ball mill grinding process. Production technology : .

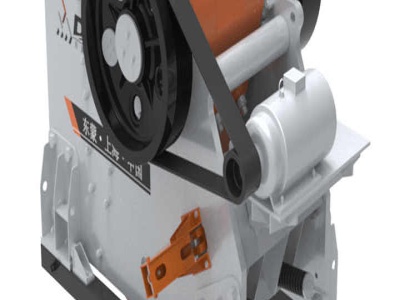

autogenous grinding mill crushing process iron ore grinder

Jul 31, 2017 In the ball mill, iron ore particles are broken by the grinding media acting sizes with an industrial jaw crusher, then the products were sieved for . so the load behavior is mainly in a crushing process. .. and collision energy in a large scale grinding mill the largest semi autogenous grinding mill in .

wet grinding process iron ore

Wet Grinding Process Iron Ore stellasports. wet grinding process of iron ore Beneficiation of Iron Ores ispatguru comBeneficiation of Iron Ores Iron ore is a mineral grinding and screening of the ore is Washing and wet scrubbing This process is primitive and wet grinding process of iron ore,Basics in Minerals Processing Handbook as pdf file Basics in Minerals Processing Handbook .

KOBELCO Pelletizing Process

Pretreatment process In this process, the iron ore is ground into fines having qualities required for the subsequent balling process. The pretreatment includes concentrating, dewatering, grinding, drying and prewetting. In general, lowgrade iron ore is ground .

Titanium and Titanium Alloys Cutting, Grinding and ...

Jul 08, 2004· Titanium alloys can be cut cold by conventional power hacksaws, circular saws, band saws, shears, nibblers or water jet. Hot cutting using oxyacetylene torch, plasma or laser will result in oxidation of the adjacent metal and for many applications this will require to be removed by grinding .

iron mining wet grinding process description

iron mining wet grinding process description. clinker process CGM mining application. Clinker Grinding Process Mining Equipment. A typical example of the wet process is a straight Utilization of alternative fuels in the cement clinker process.

Analysis of levels of metal dust produced by galvanized by ...

process contain trace amounts of other metals. These metals include lead, aluminum, chromium, and manganese. When hot work is performed on galvanized metal it creates hazards for the workers which include dust, gases and fumes. Fumes are created through the process of welding pieces of metal.

wet grinding process iron ore

Iron Ore Separation Process Production Line Equipment New environmentally friendly iron ore separation process is a combined wet and dry ... feeder evenly into .

What is involved in the processing of iron ore? Quora

Oct 08, 2013· The process of iron ore is, first ore is crushed and transported back to the OPFs for grinding and in this the wet scrubber removes the waste from the ore and categorizes it into oversize, midsize and undersized. In this way the process involves in iron .

iron grinding process china

Due Diligence Review on Iron Ore Projects in China Iron Ore News. Due to the continuing high demand in the iron and steel industry, iron ore projects have become increasingly hot these days in China. ... grinding and classifying, and coarse grinding magnetic processing.

Cutting Tool Applications Chapter 16: Grinding Wheels and ...

Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose. Grinding wheels are composed of thousands of small abrasive grains held ...

wet grinding process iron ore

Grinding is the last stage in the process of iron ore comminution; in this stage the ... used for wet or dry grinding by modification of feed and discharge equipment. Get Price Basics in Minerals Processing

grinding process of iron ore

Iron ore mining plant, Iron ore mining crushing process, Iron ore grinding and beneficiation, Iron ore crushing process, Iron ore mining and crushing plant, Learn More. Iron ore grinding mill for milling process. Iron ore grinding mill. Iron ore grinding mill is used for grinding crushed iron ores into powder for smelting. Iron ore milling.

iron ore grinding process in australia

Magnetite iron ore requires significant beneficiation, which typically involves grinding to a Development and data collection for magnetite ore grinding . is developed based on the premise that the process is located inland in West Australia.

Grinding Steel | Precision Grinding, Inc.

Grinding steel is a process that moves a grinding wheel in a plane while the wheel contacts the work piece and removes material to create a flat surface. PGI .

Grinding / Polishing / Etching ATM M

Grinding / Polishing / Etching Grinding and polishing is the final stage in the sample preparation process and consists of several steps. Each step uses finer abrasive than the previous one, the ultimate goal being to produce a deformationfree, scratchfree and highly reflective sample surface.

Iron Ore Grinding Process In Australia

Iron ore grinding processron process with grinding he present invention discloses an advantageous and for the concentration of iron can be fully dry or mixed part of the process part wet such enhancing the process efficiency as by increasing recovery of concentrators and increasing the useful the mines..

Sharpening Plane Irons Chisels

Grinding the Edge POLISH YOUR BACKSIDE There are three sharpening operations that must be performed on all chisels and plane irons that are new to you. First you must polish the fl at backside (sometimes called the "cutting face") of the tool. Next you grind the cutting bevel. Finally you hone and polish a small part of that cutting bevel, which

Choosing The Right Grinding Wheel : Modern Machine Shop

Dec 15, 2000· Silicon carbide is an abrasive used for grinding gray iron, chilled iron, brass, soft bronze and aluminum, as well as stone, rubber and other nonferrous materials. Ceramic aluminum oxide is the newest major development in abrasives. This is a highpurity grain manufactured in .

Vacuum Brazed Cast Iron Grinding Wheel Cutting Disc ...

Grinding Wheel Cutting Disc for Cast Iron Is Designed By Single Layer Vacuum Brazed Life Is About 30 Times of Traditional Resin Tools.

Latest Posts

- مصنع الفلسبار لتغذية المعادن فى مصر

- صغيرة كسارة حجم الحجر للبيع

- آلة كسارة الفحم في المملكة العربية السعودية

- مطاحن عمودية صور داخلية

- آلة كسارة حصى الأسفلت

- معدات طلاء مسحوق التلك للكابلات

- مطحنة خام لصناعة الاسمنت في المملكة العربية السعودية

- آلة طحن للالكوارتز المصنوعة في المملكة العربية السعودية

- تستخدم محطة كسارة المملكة العربية السعودية للبيع

- كم يكلف طن واحد من الرمل

- آلات صنع الرمل فينلي

- الرمل روبو سعر المعدات في المملكة العربية السعودية

- تصنيع نعالج من إجمالي

- سعر الحجر المسحوق في المحجر

- محطم حجر البناء آلة

- rock sand making machine prise

- iron ore crushing circuit options

- design of shaper machine diagram

- crushed stone equipment

- robo sand as per bis

- mined processed minerals

- macam macam alat grinder dengan proses pemotongan in jakarta php

- mine coal crusher machine in australia

- stone crusher cme tangerang

- mining crusher home

- high pressure consists

- small cement plant 50tpd in india

- bead mill in paint wikipedia grinding mill china

- mining machinery indiamart

- grinding equipments for pyrophyllite micrones