ore processing nickel

ore processing nickel

Nickel Ore Process, Nickel Ore Mining Equipment Xinhai. Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation method when processing copper sulfide nickel ore, magnetic separating and gravity .

copper nickel ore processing

Nickel Ore Process, Nickel Ore Mining Equipment Xinhai. Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation method when processing copper sulfide nickel ore, magnetic separating and gravity .

Nickel Ore Beneficiation Processing Plant For Sale China ...

Nickel Ore Beneficiation Plant or Nickel Ore Processing Plant, Nickel Ore Flotation Process is a combining system that recovers the nickel from its ore, there are several different solutions for the nickel ore Beneficiation Plant depends on the contents of nickel and iron, the commonly used three solutions are nickel ore flotation process ...

Nickel

The sulphide ores we mine contain more than just nickel. Other elements are often found and by extracting and processing nickel, our operations also produce cobalt, copper and precious metals. Nickel and the humankind have a longtime partnership: the use of the metal has been traced as far back as 3500

ore processing nickel

Sulfidic Ore Processing, Nickel Smelting and Refining 351 should be recycled, nickel sulfide ores often contain other metals. Chat Now; Nickel Mining and Processing: Everything you Need to, Third in our mining series, find out all you need to know about nickel mining and processing .

nickel ore processing plant

Kiewit :: Ore Processing. Long Harbour Nickel Processing Plant Long Harbour, Located on the Island of Newfoundland, Vale's Long Harbour Processing Plant is one of the largest in the world to use a new hydrometallurgical process that will refine 50,000 tonnes per year of nickel ore in a more economical and environmentally friendly manner.

Eagle | Lundin Mining Corporation

Ore from the Eagle mine is trucked to the Humboldt mill, site of a former iron ore processing facility, for processing into concentrates. The Humboldt mill lies approximately 60 km west of Marquette. Operation Overview. Eagle mine is an approximately 2,000 tonnes per day (tpd) underground nickel .

Copper Mining and Processing: Processing of Copper Ores ...

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

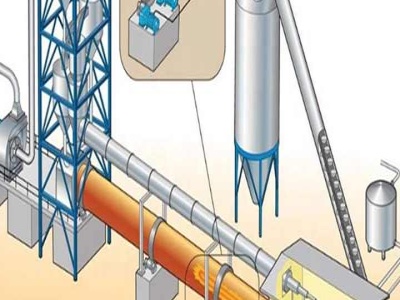

An innovative process | Koniambo Nickel

From ore to ferronickel. A brief description of the cuttingedge technologies we use at Koniambo Nickel's industrial complex, with an ore processing flowchart, from extraction to export.

Rio Tuba and Coral Bay nickel mining and processing in ...

The plant is designed to extract nickel from lowgrade ores previously considered waste. Sumitomo provides a hydrometallurgical technology whereby laterite ore, a low nickel content oxidized ore, is smelted in sulfuric acid and heated to high temperatures, and only nickel and cobalt are eluted in the liquid by applying high pressure.

Portable XRF for Nickel Laterite Exploration, Grade ...

Processing and extraction of Nickel Laterites often requires very largescale acid leaching or roasting in rotating kilns or autoclaves, so blending a constant ore feed is .

Goro Nickel Project, South Pacific Island of New Caledonia ...

The Goro Nickel mine is the largest mining projects in New Caledonia. Around 4 million tonnes of dry ore are expected to be removed each year at the Goro Nickel site in New Caledonia. Equipment for the Goro Nickel plant is being supplied by Komatsu, ABB, Cimprogetti. Haulage is undertaken at the site in New Caledonia by a fleet of dumper trucks.

Copper. One more ore processing YouTube

Mar 29, 2017· KAZ Minerals presents Copper is one of the top seven metals known since the ancient time. Actually, humankind knows over 170 coppercontaining minerals. Copper melts at 1,0830C. Copper and zinc ...

Nickel Ore Mining – PT Ceria Nugraha Indotama | Nickel ...

Latest ore reserves of Wolo, Jessica, Ruby and Samaenre prospects, a small portion of Lapaopao block, in May 2018 by the same competent person reported a total of million tonnes (wet) with an average of % nickel. The ore reserve is for direct shipping ore (DSO).

![[Bob's Mod] What do you do with all the nickel ore? : factorio](/2czemp0/1047.jpg)

![[Bob's Mod] What do you do with all the nickel ore? : factorio](/2czemp0/498.jpg)

[Bob's Mod] What do you do with all the nickel ore? : factorio

Process it for acid and nickel bars, then dump the bars into lead processing for even more acid (it turns out 'too much battery acid' is a real problem that exists so make sure there's space for tanks so the lead doesn't jam) and free silver. There's a lot of overage though, so I've got like half a warehouse of nickel .

USA Nickel extraction process Google Patents

1. A process for recovering an increased quantity of nickel values from a lowgrade complex nickel ore said process comprising simultaneously grinding and leaching with an aqueous ammonia and ammonium salt solution of a comminuted lowgrade nickel ore characterized by having a nickel content of not more than about percent by weight and a sulfur to nickel ratio of one or less for a time ...

Nickel Processing '12

Keynote Lecture: Hydropyro integration in the processing of nickel laterites A. Oxley (Alyssum Ventures Ltd, UK) and N. Barcza (Metallurgical Engineering Consultant, South Africa)) Direct extraction of nickel and iron from laterite ore using Carbonyl Process Terekhov and Emmanuel (CVMR® Corporation, Canada)

ABB solves transmitter erosion problem at nickel ore ...

October 7, 2009 Highly abrasive nickel ore slurry flow at a Canadian Xstrata nickel ore processing mill caused serious erosion of metallic diaphragms in pressure transmitters even when retofitted with a protective rubber pad. Transmitters failed unpredictably and frequently, requiring ...

CopperNickel ores Danafloat Home

CopperNickel ores Pentlandite ((Ni,Fe)S) is the most important nickel sulphide mineral and is often associated with nickelcontaining pyrrhotite and chalcopyrite. Gangue minerals can include talc and other troublesome silicates which must be dispersed and/or depressed.

Implications of Indonesia's Decision to Relax the Nickel ...

Jan 16, 2017· Nickel miners who have allocated at least 30% of their smelting capacity for processing lowgrade ore will be allowed to export any excess lowgrade nickel ore. Exports are permitted for a period of five years from the date of the regulation.

Nickel Ore | Subnautica Wiki | FANDOM powered by Wikia

Nickel Ore is a raw material that is found exclusively in the Lost River and some parts of the Inactive Lava Zone. It can be found as a Large Resource Deposit and as loose chunks of ore on the seabed. It is used to create several vehicle upgrades.

Nickel Processing | Nickel | Smelting

FerroNickel Process Besides laterite ore, coke and/or coal are the other second raw materials that are needed in ferronickel production. Coke or coal is needed as a reducing agent. FerroNickel Process 1. Drying takes place in a directlyfired rotary dryer where the moisture content can be .

China's Tsingshan rains on nickel bulls' party: Andy Home ...

Oct 30, 2018· Such is the company's reputation for innovation and disruption that noone is dismissing its ability to close the processing loop between nickel ore and nickel sulphate in recordbreaking time.

Eagle | Lundin Mining Corporation

Ore from the Eagle mine is trucked to the Humboldt mill, site of a former iron ore processing facility, for processing into concentrates. The Humboldt mill lies approximately 60 km west of Marquette. Operation Overview. Eagle mine is an approximately 2,000 tonnes per day (tpd) underground nickel .

Elemental Analysis by EDXRF for Nickel Ore Processing

Austin, TX – February 14, 2012. Applied Rigaku Technologies, Inc. has published a new application report demonstrating an energy dispersive Xray fluorescence (EDXRF) method for the determination of atomic elements and oxides in the processing steps associated with nickel refining. Analysis of nickel concentrate, filter cake, furnace matte and furnace slag is demonstrated in

Latest Posts

- تشغيل كسارة في taiping

- ذروة طحن الدقيق

- العقود الحجر الجيري في تاميل نادو

- كسارة الحجر جعل ملف الصورة الأمامية

- قدرة طاحونة قضيب

- البنتونيت كسارة مصنعين

- المزايا الاقتصادية لتعدين الحجر الرملي

- الكسارات المحمولة والمتنقلة

- مصر التعدين سعر كسارة

- فيبرو شاشة المصنعين في مصر

- صخرة محطم مصر

- جسيم كسارة لفة مزدوجة

- الكسارات SBM للبيع أو استئجار

- قائمة أسعار مطحنة 3stamp

- تركز الحديد تكلفة الرمل

- k roller assembly of raymond mill r f

- equipment operaing characterstics of cone crusher

- used wood chipper for sale

- crushed stone plant uae

- crusher yang lokasi

- jaw crushing stone jaw crusher from brasil

- stone crusher kobe

- gold ore impact crusher provider in indonessia

- mining equipments distributors association in africa

- carrying out concrete bursting and crushing operations ppt lecture note

- new recycled aggregate concrete ppt

- mobile

- how gyratory working

- gold refining at minataur process explained

- cedarapids crusher twin jaw