why coal mill motor low power factor design

LCI'S AND SYNCHRONOUS MOTORS APPLIED TO .

the possibility of providing leading power factor to reduce the reactive power demands seen by the utility feeding the cement plant. It was theorized that, if sufficient power factor correction could be obtained, the payback period of the incremental additional cost of the synchronous motor drive system would be very short.

motors coals crushers

difference in speed of coal crusher and motor shaft design and analysis of a horizontal shaft impact. This type of crusher is generally usedwith soft materials like .

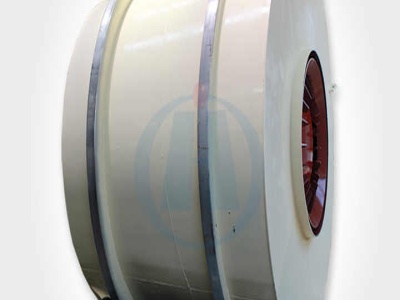

High Voltage Motors New India Electricals Ltd.

High Voltage Motor. New India offers a wide range of High Voltage Motors from 2 to 20 Poles, up to 25 MW in Closed Air Circuit Water Cooled (CACW), Closed Air Circuit Air Cooled (CACA), Totally Enclosed Tube Ventilated Motors (TETV), Screen Protected Drip Proof (SPDP) and Totally Enclosed Fan Cooled (TEFC) for applications in Power, Steel, Sugar, Paper and other industries.

power consumption coal grinding

Our ATOX® Coal Mill is a durable grinding solution that can grind all types of raw coal to your desired fineness. Español An efficient separator leads to a number of benefits including low specific power consumption for the mill motor, low vibrations, energy savings due to minimal pressure loss, and optimised airflow. Get Price

Application of reactive power compensation for underground ...

The underground coal mine asynchronous motor is used in a wide range and is the main reactive load of the underground power grid. Because of its low power factor, it greatly increases the cost of electricity consumption of enterprises, and at the same time reduces the utilization of equipment power and increases the loss of the line.

why is hot inside a coal mine

why is hot inside a coal mine . why are coal mines deep inside the earth why is hot inside a coal mine. why are coal mines deep inside the earth why are coal mines deep inside the earth Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, . Contact Supplier

Power Factor in Electrical Energy Management

Power Factor in Electrical Energy Management Course Content What is Power Factor? Power factor is the percentage of electricity that is being used to do useful work. It is defined as the ratio of 'active or actual power' used in the circuit measured in watts or kilowatts (W or

coal mill problem low grinding

Operating hours Involuntary downtime hours kWh/tonne (mill motor + fan + seperator) Product fineness on 90/212 microns for raw mill,coal mill and blaines for cement mill Mill output, Too low. Mill product, Too coarse Mill product, Too fine. Type of problem Mill outlet temperature, Too high. Mill outlet temperature, Too low.

power usage in coal mills

Coal mill for power plants manufacturer SBM produces vertical mill,Raymond mill,Supermicro mill and MTM mill for sale in Coalfired Thermal Power mills such vertical mil is used to grind coal into powder in power plants.

Application of reactive power compensation for underground ...

Application of reactive power compensation for underground lowvoltage asynchronous motor in coal mine. First, the industry situation. The underground coal mine asynchronous motor is used in a wide range and is the main reactive load of the underground power grid.

define coal mill

Daw Mill Wikipedia, the free encyclopedia. Daw Mill was a coal mine located near the village of Arley, near Nuneaton, in the English county of Warwickshire. The mine was Britain's biggest coal producer. On 7 ...

why chrome ore need crushing

why coal mill motor low power factor design I purchased a 12"x9" hammer mill and 4'x8' shaker table from Zenth Mining and Metals because they helped me choose the .

coal mill amps new grinding

Coal crushing machine and grinding mill for processing plant Following on the opening of two new coal power which produces around 15 amps 12 volts. Vertical Roller Mills for Coal Grinding | Vertical Roller Mills for Coal Grinding.

Low Cost Hammer Mill Crusher

Processing And Pelletizing Of Low Grade; Why Coal Mill Motor Low Power Factor Design; Low Quality Products; Low Consumption And Top Quality Grinding Ball Mill; Mobile Series Crushing Plant With Low Cost China; Low Grade Iron Ore Beneficiation Plant Equipment; Low Silica Lime Stone Mines In India; Mobile Stone Crusher 50 Tph 300 Tph For Sale With Low Cost

low power factor of crusher motor

Coal Mill; Mobile Crushing Plant. ... new design high quality and low price jaw crusher; ... In this paper, the effects of low power factor on main motors which use in ... Theinfluence of power factor correction on the motors, transformers and ..... ×130. Induction Motor. Raw Material Mill. .

why crushed coal

Seepage properties of crushed coal particles ScienceDirect. Gas release from the crushed coal formation during coal mining poses a threat to the normal storage and gas transport within coal seam. This sort of release is. Get Price

what is coal mill Mine Equipments

Coal Mill Crusher In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. Coal Mill Classifier Repair Case Study | Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace.

Ball Mill Drives Mineral Processing Metallurgy

Where power exceeds this, drives become so large and motors become special, resulting in an uneconomical application. Generally the driven mill sheave is of split hub construction to facilitate field assembly. Vbelt drives allow use of higher speed motors, generally low in initial cost. Motor speeds should be between 580 and 1160 rpm.

Latest Posts

- خدمات جيولوجيا الفحم واستشارات التعدين

- الجرانيت الحجر كسارة

- قادوس تغذية تلقائي لاستعادة الذهب

- أدوات وآلات التعدين

- مطحنة ذهب مصر في عمان

- الكوارتز طحن آلات

- آلة محطم المحمول

- كيفية اختيار كسارة المطرقة

- تشغيل طاحونة الكرة

- ريموند قدرة مطحنة

- أجزاء الفك محطم المملكة العربية السعودية

- مصنع حجر مخروط محطم

- كسارة متنقلة وآلات الشطف المتنقلة الصين

- رمل السيليكا إثراء النبات

- خام المعادن وحدة المعالجة محطم الصانع

- diamonds quarry south africa

- big gold trommel for sale

- clay fines vibration

- rajmahal coal mining project

- limestone crushing machine filetype pdf

- electrical handing machine

- distribusi batu di indonesia

- stone crushing producing

- gold mining process in nigeria

- dolomite suppliers from indonesia

- gambar auto cad stone crhser

- screening machines double wash

- yk1545 mining vibrating screen mineral ore vibrating screen

- impact of ipcc in grinding mill

- concrete crusher plant pricing