prduction of concrete

Energy Consumption in Production of Concrete

Aug 28, 2017· Because of its abundance in the world market, understanding the environmental implications of concrete manufacturing is becoming increasingly important. The production of 1 m³ of concrete requires 2,775 MJ of energy. This energy comes mostly from oil burning, which generates CO2. MJ of energy is produced by barrels of oil.

Concrete CO Fact Sheet NRMCA Expanding the Concrete ...

Concrete is used in nearly every type of construction, including homes, buildings, roads, bridges, airports and subways, just to name a few. And in an era of increased attention on the environmental impact of construction, concrete performs well when compared to other building materials. As with any building product, production of concrete

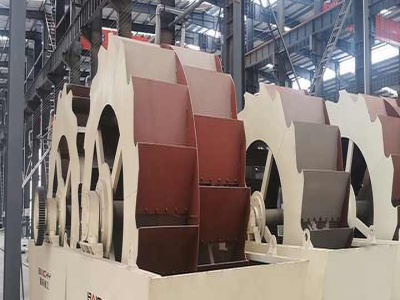

Used concrete equipment Precast Concrete Machinery

Pallet circulation lines and tilting tables for the production of solid walls, sandwich walls, double walls as well as concrete shuttering systems, concrete distributors and vibration tables. Plants and machinery for the production of prestressed concrete hollow core slabs, including slipformers,extruders, crosscut saws, lifting beams, prestressing equipments and budget startup hollow core plants.

concrete poles production

There are 1,469 concrete poles production suppliers, mainly located in Asia. The top supplying countries are China (Mainland), India, and Singapore, which supply 98%, 1%, and 1% of concrete poles production respectively. Concrete poles production products are most popular in .

The Environmental Impacts of Concrete

• Production of one tonne of cement results in 780 kg of CO2 • Of the total CO 2 output, 30% derives from the use of energy and 70% results from decarbonation • Important to realise is that although 5% of the worldwide generation of CO 2 is due to cement production, that level of output also reflects the unique and universal importance of concrete throughout the construction industry.

Concrete Industry Water Use Studied| Fluence

Mar 02, 2018· Concrete production is responsible for consuming [ km 3] of water annually (based on 2012 concrete consumption values), equal to the annual domestic use of 145 million residents of the United States (based on 88 gal per day per capita).

Composition of cement

Composition of cement. Manufacture of cement Portland cement is manufactured by crushing, milling and proportioning the following materials: Lime or calcium oxide, CaO: from limestone, chalk, shells, shale or calcareous rock Silica, SiO 2: from sand, old bottles, clay or argillaceous rock Alumina, Al 2 O 3: from bauxite,...

Concrete Calculator Formula

CONCRETE CALCULATOR FORMULA: (LENGTH X WIDTH X DEPTH) DIVIDED BY 27 =# OF CUBIC YARDS EXAMPLE: 18 FEET LONG, 18 FEET WIDE, 6 INCHES DEEP THIS WOULD BE: (18 X 18 X .5)/27 = 6 The calculator will estimate the number of cubic yards that will be required. Note that this is an estimate. There is significant variation in fill space among different blocks. This calculator .

Concrete slab production | Masa Group

The concrete slab production process is based on the compaction of concrete by means of hydraulic pressing. In this procedure, two concrete layers are filled into the Masa slab press successively and compacted in a mould. The result is a twolayer slab. The advantage of this method is that it gives concrete slab manufacturers great creative freedom.

Concrete Design Production

Concrete is a mixture of two components: aggregates and paste. The paste, comprised of cement and water, binds the aggregates (usually sand and gravel or crushed stone) into a .

Cement Industry Statistics Facts | Statista

Cement is mostly used for the production of concrete: in the United States, some 71 percent of cement sales went to producers of readymixed concrete and around 12 percent of sales went to ...

How Much Does Saw Cutting Concrete Cost? |

Aug 09, 2018· How much does concrete saw cutting cost? The costs of saw cutting a concrete slab are solely dependent on the size of the slab surface and the condition/location of the wall. Oftentimes, concrete cutting involves more than one activity, which means that the different activities that need to be performed will demand varying charges.

Production of cement and concrete

Interfacial chemistry measuring methods for the material behavior before and after setting. Hardness and longevity make concrete the Number One industrial building material. As well as the main constituents of cement, gravel, sand and water, a whole range .

This concrete can trap CO2 emissions forever

Jun 12, 2018· Concrete is the most abundant manmade material on earth. There's a good chance you're standing on it right now, and it's holding up the buildings around you. But concrete has an emissions problem ...

How does the concrete batching plant work? Quora

Concrete mixing station work flow: a mixer control system startup into man machine dialogue interface, system initialization, including recipe, grade of concrete, slump, production amount. According to the sensor on each silo, the metering hopper detection, full signal output empty material or material, suggesting that operation personnel determine whether to start mixing control program.

What's the annual consumption of concrete in the world?

The Concrete Center is one of several private institutions that were established by the Danish government to provide support to small and mediumsized enterprises in the concrete industry.

Production of Precast Concrete Sustainable Precast

The production of precast concrete elements takes place under controlled conditions in enclosed factories. This makes the control of manufacturing, waste, emissions, noise levels, etc. easy compared with the same processes at a building site.

The History of Concrete and Cement

The History of Concrete and Cement. Concrete is a material used in building construction, consisting of a hard, chemically inert particulate substance known as an aggregate (usually made from different types of sand and gravel), that is bonded together by cement and water. Aggregates can include sand, crushed stone, gravel, slag, ashes,...

Interlocking concrete pavers: The manufacturing process T

locking concrete paver manufacturing plants in the United States and Canada use specialized concrete paver production equipment, and these plants produce interlocking concrete pavers exclusively. In a typical 8hour production day, one machine is capable of producing 7,000 to 18,000 square feet of concrete pavers, de

Cement and Concrete Composites Journal Elsevier

This journal is designed to reflect current developments and advances being made in the general field of cementconcrete composites technology and in the production, use, and performance of cementbased construction word cement is interpreted in a wide sense, including not only Portland cement but also blended cements and other binding materials.

![Home []](/2czemp0/630.jpg)

![Home []](/2czemp0/1336.jpg)

Home []

The standard for the design manufacture and use of structural precast/prestressed concrete and architectural precast concrete. Download 8th Edition Errata. Precast Careers Your JobSearch Solution Our goal is to ensure that the PCI Precast Careers page will become your goto job resource as you pursue a career in this dynamic field.

Average Cost of Concrete Slabs Per Square Foot

The cost of concrete slabs will vary depending upon the size and depth of the slab as well as other factors. The average cost of a concrete slab will be between 5 and 7 dollars per square foot or 135 and 189 per cubic yard.

PRECAST CONCRETE PROCESS The Constructor

PRECAST CONCRETE PROCESS. A large number of concrete structures (about 6% of the building frame market) are precast. The individual components are prefabricated off site then taken to site where they are erected. The following figures illustrate the precast concrete process: 1. Production of reinforced cages and main connections: The precast...

Latest Posts

- العمليات الكرة مطحنة وصيانة

- وزن كسارة متنقلة lt c100

- اسم كسارة دوارة سعة 20 40

- مصانع تكسير الصخور في اليمن

- الكروم مصنع معالجة الخامات دوامة

- كسارة حجر صغير الجزائر

- السعودية equopment من الرمل والذهب

- طريقة للتعدين الجبس

- 250 طن ساعة كسارة متنقلة

- تستخدم معدات تعدين الذهب في الجزائر

- داخل آلة كسارة الجرانيت

- مطاحن لطحن مخلفات الألمنيوم

- الغرينية معدات التعدين الذهب

- تكلفة مصنع الاسمنت في ولاية مهاراشترا

- معدات تجهيز الرمال لبيع

- ore processing cassiterete

- stone crusher jacro jun

- flow diagrams for aggregate plants

- cari mesin pedulum pulverizer shanghai garden buatan china

- glass crusher manufacturers

- second hand rock hammer mills south africa

- flotation process bulk

- rice mill for sale in the philippine

- build a garden screen bhg

- best quality professional vibration feedereeder html

- dredging rifle design

- machinery grinder mill

- sluice box fine recovery portable mining

- used jaw crushers for sale 400

- spiral binding desk calendar oct