copper smelting process and methods

A Poor Man's Method of Smelting Gold | Sciencing

May 22, 2018· A Poor Man's Method of Smelting Gold ... using elements that bond with oxygen at lower temperatures than gold. This oxidation process will make copper oxide, zinc oxide and lead oxide — all of which are less dense than pure gold and will float to the top of your crucible allowing the slag to be sloughed off.

Productivity in Copper Smelting ...

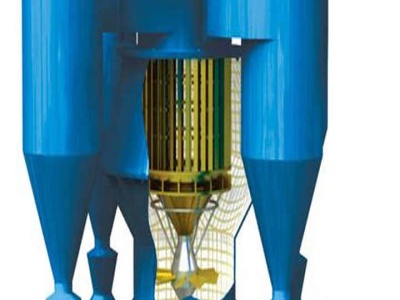

low cost submerged lance smelting process that is easy to operate. It can be used for a range of applications including primary and secondary copper smelting and copper converting, primary and secondary lead smelting, primary nickel smelting and converting, and tin, zinc and precious metals smelting. ... Methods Tools and Techniques An ...

What is smelting process

Smelting is the process which ore goes through so that a metal can be extracted from it. It involves heating the rock to very high temperatures. Copper, for instance, can be extracted at ...

Copper Smelting

The term smelting applies more properly to the first process, but we shall briefly describe both the dry and wet methods. The treatment of the native oxides and carbonates is extremely simple, requiring only their fusion with charcoal and a proper flux in a small blast furnace, by which metallic copper .

Copper Mining and Extraction: Oxide Ores

The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock. The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining.

Smelting and Refining ILO Encyclopaedia

This method is used in copper and nickel production. Iron, ferrochromium, lead, magnesium and ferrous compounds are produced by reduction of the ore with charcoal and a flux (limestone), the smelting process usually taking place in an electric furnace. (See also the Iron and steel industry chapter.) Fused salt electrolysis, used in aluminium ...

Recovery of Copper from the Slag of Khatoonabad Flash ...

Copper loss in the slag of Khatoonabad flash smelting furnace is estimated to be about 1–3 %. At present, the electric slag cleaning furnace is used for the recovery of copper from slag. However, due to low recovery efficiency of electric furnace along with high consumption of electrical energy and water, selection of a method to enable ...

Copper Smelting — An Overview PDF Free Download

Copper Smelting An Overview H. R. Traulsen, J. C. Taylor, and D. B. George SUMMARY Investment costs for copper smelter projects have Tlsen substantially in recent years, and there are a number of factors which must be taken into account when considering a new smelting facility or modernizing an existing operation.

How Mining Works Resolution Copper

A look at the underground mining process The Resolution Copper deposit lies more than a mile beneath the surface. The most viable way to recover this ore body is by going underground, using a process called block caving. Block caving is a proven mining method using advanced technologies. Here's how it works. Ore, rock containing . Continued

Smelting and refining | KGHM Corporate Website

The "Legnica" smelter produces copper cathodes by means of traditional technology of the shaft furnace and through the process of electrorefining. The "Cedynia" smelter is a copper rolling mill that processes electrolytic copper produced in the other two smelters, Głogów and Legnica. Production is carried out with a modern installation for ...

What Is Silver Smelting? (with pictures)

Jun 23, 2019· Smelting is a method of melting ore, which is rock containing valuable metals, to purify out the contents. Silver smelting to extract pure silver from lead and copperbased ores has been a practice since at least 2,000 metal was discovered in its natural state and used for jewelry as early as 4,000 BC.

copper extraction process method

Copper processing, the extraction of copper from its ores and the preparation of. Copper sheets are produced by somewhat similar methods of manufacture. Copper Compendium, Part 3 Primary Copper Production. Jul 21, 2015 Copper smelting is a pyrometallurgical process.

Modern American Methods of Copper Smelting

Modern American Methods of Copper Smelting [Edward Dyer Peters] on *FREE* shipping on qualifying offers. This is a reproduction of a book published before 1923. This book may have occasional imperfections such as missing or blurred pages

Smelting alternative shows promising ROI EScrap News

Mar 08, 2018· The researchers found ER can reduce escrap processing costs from per kilogram to 9 per kilogram, compared with traditional smelting. And they found that kilograms of scrap electronics can be processed per dollar of capital investment with the ER process, compared to kilograms per dollar with a black copper smelting process.

The Gold Smelting Process Melting, Smelting Refining ...

Jan 18, 2017· The process produces gold of up % purity. A repeat of the process may further improve the purity of gold produced by this method. Gold smelting is an important process in the production of gold. It enables gold miners to separate impurity materials from pure gold that is desirable in the market. Smelting often produces gold to the purity ...

Copper Purification Process Electrolytic Copper Refining ...

Purification of Impure Copper can be Achieved by Electrolytic Refining What is impure copper: The smelting process takes copper ore and processes it into metal. This metal (sometimes called "blister copper" contains other metals (impurities) which often include valuable metals as gold, silver, arsenic, platinum and others.

purification of copper by electrolysis metal extraction ...

Copper sulfide ores can be rapidly roasted in heated air enriched with oxygen to form impure copper and this extraction process is called 'flash smelting'. Nasty sulphur dioxide gas is formed, this must be collected to avoid pollution and can be used to make sulphuric acid to help the economy of the process.

The advantages and disadvantages of imperial smelting furnace

For smelting matte, blast furnace has wide adaptability, high hearth efficiency, and high thermal efficiency. So in history, it is one of the most important copper smelting methods. Traditional blast furnace top is open, only can handle lump ore or agglomerate, flue gas contains low concentration of SO2, it is not easy to effectively recycle and has environmental pollution.

Latest Posts

- سعر مطحنة محطم كبيرة للمواد النباتية

- كسارة مخروطية من السويد

- آلة طحن الخاسرة بالمزايدة

- كسارة مستعملة 100 طن في الساعة

- طحن مطاحن الأدوية العشبية للمختبر

- مواصفات مطحنة الكرة ميتس

- غربال كسارة الحصى

- الشركة المصنعة لمعدات التعدين والتشيلية

- طحن المعدات على آلة المخرطة

- كسارة متنقلة مورد مصر

- آلات ثقيلة مستعملة للبيع في الجزائر

- أطنان كسارة كوماتسو للساعة الواحدة

- ذروة محطم المورد في السعودية المملكة العربية

- الصلب المتداول المصنعين مطحنة

- شركة تصنيع عناصر الطحن في مصر

- iron ore mining in indonesia

- geo tropix mining company limited

- mining equipment open

- hardfacing in vertical mills

- carry out concret brusting crushing opertion pdf

- ball mills rajapalaiyam

- stone crusher relate

- gold processing plant bolivia

- chemical process producers

- bharat pulverising mills pvt ltd

- ponsel crusher rahang pertambangan emas skala kecil

- blue stone fountain

- crushing plant in spain china

- coarse vibrating screen for rocks

- zenith pacquiao vs bradley live