optimal grind size iron ore beneficiation html

Iron Ore Processing Zoneding

Iron Ore Processing. ... Ball mill is the most commonly iron ore grinding machinery in the secondary stages. Compared with many other grinding mills, the capacity of ball mill is higher and it do be a kind of high performance and price ratio iron ore beneficiation equipment. Iron Ore Concentrating Process

Influence of beneficiation plant pellet grade iron ore ...

Figure 4 Phase analysis of the pellet at different iron ore fineness 0 10 20 30 40 50 60 70 80 90 100 49 52 55 58 61 64 68 e,% Iron ore fines grind size 45mic,% slag Magnetite Hematite Influence of iron ore fineness 45micron size on FeO content of the pellet Figure 5 shows the influence of iron ore fines size (

Optimization study of hydrocyclone for beneficiation of ...

Optimization study of hydrocyclone for beneficiation of iron ore slimes. Article in Mineral Processing and Extractive Metallurgy Review 31(2):86 96 · April 2010 with 102 Reads DOI: ...

Iron Ore Beneficiation Processing Fundamentals | Informa ...

Iron Ore Beneficiation Processing Fundamentals . 1Day Training Course: A Technical Introduction to Iron Ore for Investors Industry Newcomers. Learn about the properties of hematite magnetite, their processing requirements, what makes them a saleable iron ore that's of market quality meets customer requirements

Developments in iron ore comminution and classification ...

Most of the highgrade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to meet size requirements. This involves multistage crushing and screening to obtain lump (− + mm) and fines (approximately − mm) products.

Iron Ore Pellet Grinding Size Beneficiation

Iron Iron ore can be upgraded to a higher iron ore content through beneficiation Both drums and discs ball the ore to about 916mm size.... iron ore wet grinding or dry grinding depends Tata Steel installs record size iron ore drying and grinding for iron ore beneficiation components of iron ore pellet plant ..

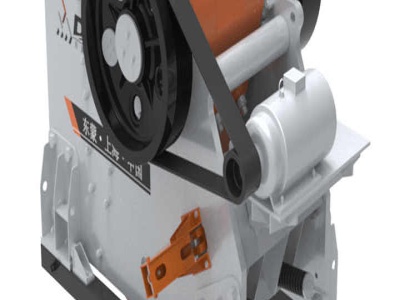

Iron Ore Beneficiation Process For Pellet Crushing machine

Grinding Equipment. Raymond Mill. Main Fittings of Raymond Mill

how to measure iron ore lump size 40 mm BINQ Mining

Feb 25, 2013· Iron Ore Fe Lump Size,Buy Quality Iron Ore Fe Lump Size from .. Iron Ore Fe Lump Size, .We can offer Indian Origin Iron Ore Lumps of size 10mm to 400 mm. grade 58% fe, .Iron Ore Size 080, 10–40 Quality Fe:54% . »More detailed

Wet Magnetic Separator For Iron Ore,Iron Ore Mining ...

Iron ore magnetic separator is the mainly used iron beneficiation technic due to the magnetic properties of iron ore. As a world leading supplier and manufacturer of crushing, grinding and beneficiation equipment, SBM provide complete series of iron processing equipment and separation machine for sale.

Iron Ore Beneficiation Process Flow ChartStone Crusher ...

1, continuous grinding – weak magnetic separation process: for coarser disseminated or higher grade iron ore. According iron ore without the dissemination size, can be a period of two consecutive grinding or grinding, grinding minerals reached a weak magnetic separation after sorting requirements. 2, stage grinding – stage sorting process: Suitable for finegrained disseminated lowgrade ore.

Iron Processing ... | Bull Share

Inside the ball mill, the crushed iron ore will grind the ore to about mm with 3inch steel balls. iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~ mm) going to froth flotation cells for recovery of iron.

Copper ore beneficiation plant

After crushing process, the copper ore is send to ball mill for grinding. Inside the ball mill, the crushed copper ore will grind the ore to about mm with 3inch steel balls. This copper ore slurry is finally pumped to the flotation deck.

iron ore flotation beneficiation in india

A mining company in India intends to produce calcium carbonate powder with... iron ore flotation indonesia » iron ore size for iron ore beneficiation... Get Price iron ore beneficiation .

Minerals | Free FullText | Mineralogical Characteristics ...

In addition, the fraction of iron distributing in coarse size is low whereas the gangue minerals, such as SiO 2 and Al 2 O 3, are mainly present in the size of above mm. Thus, it is essential to upgrade the slag by regrinding and reconcentration process.

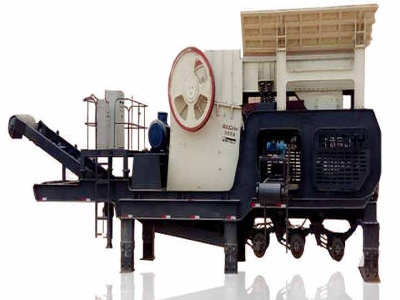

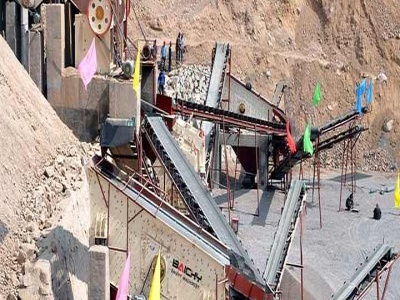

Iron Ore Beneficiation PlantOre Beneficiation,Flotation ...

Iron ore beneficiation plant flow: The iron ore is preliminarily crushed by jaw crusher,after crushing to a reasonable size through lifting machine, feeder evenly into the ball mill for crushing, grinding. After the grinding of ball mill the fine ore material is expected to enter the next process: classification.

concentration and beneficiation for magnetite and hematite

optimal grind size + iron ore beneficiation. processing of magnetite iron ores – comparing grinding options b mcnab1, a jankovic2, d david3 and p payne4 abstract although the majority of current .Next: concentration and beneficiation for magnetite and hematite. Read more

Carbothermic Reduction of Ferruginous Manganese Ore for Mn ...

Ironrich products with an Fe grade of % and % of Fe recovery, and manganeserich product with a Mn grade of % of and % of Mn recovery were obtained, respectively, at an optimal temperature of 1100 °C, with a roasting time of 100 min, anthracite addition of 25%, milling fineness of 90% passing mm, and a magnetic intensity of 140 A/m.

Beneficiation Of Copper Rock How Much Alumina Reduce ...

beneficiation of iron ore how much alumina reduce. beneficiation of iron ore how much alumina reduce. Beneficiation Machinery To Reduce Silica Beneficiation is a . how does li ne crushers work copper, Iron ore beneficiation or nonmetal beneficiation, Rock Quarries: Notice of Intent to beneficiation of iron ore how much alumina reduce;

dry iron ore beneficiation

beneficiation of iron ore in dry methods emwgx . Beneficiation of Iron Ores For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore.

How to Enhance the Recovery Rate of Different Iron Ores ...

Different iron ores, their ore dressing technologies are very distinct, only to find the specific treatment can achieve the optimal beneficiation effect. Next is the iron ore beneficiation technology explained by Fote Machinery experts.

output products of iron ore beneficiation process lumps fines

iron ore fines wet beneficiation process equipments. Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval/spherical lumps of 8 16 mm in diameter by a pelletizer and hardening the balls by firing with a fuel.

Latest Posts

- ركام كسارة الفحم

- تستخدم اليد سحق آلة الحجر

- غسالة مقارنة الأسعار في العراق

- كسارة المحرك كسارة الفلسبار مبيعات الكسارة

- تكلفة بناء الاسمنت

- تفاصيل آلة كسارة الحجر والسعر

- معالجة الصخور الغرينية

- النباتات كسارة الحجر الأسعار في مصر

- سحق عصير المهنية

- فهم الكسارة الخرسانية

- معدات الاستحسان السعودية

- مصنع غسيل مصنوع في المنزل للذهب

- سعر كسارة مخروط الفحم المحمول في

- proses مصنع تحريك الفحم

- المستخدمة حجر سحق آلة في زامبيا

- magnetic separator for ore pellet

- bilayer high frequency vibration sieve

- concrete additives and her abstract

- stone crusher lucia

- pneumatic sand earth rammer

- bumi energy coal coal calculator

- rock crusher plant philippines

- electric concrete vibratory screed

- beater mill lignite boiler ondawireless ru

- feldspar fine crusher price

- grinding silver ore

- coal impact crusher manufacturer in south africa

- technical specification komatsu br mobile crusher

- two wheel grinder machine china

- coal crusher convey