chemical free processing of mine tailings

Red Valve Products | Red Valve

Mining Chemicals; Processing Equipment; Mixing and Sparging; Mine Tailings; Slurry Handling; Remote Mines; Chemical Industry. Air Sparging; Lime Slurry and pH Control; Paper Making Liquors; Mining and Ore Processing; Pulp and Paper. Pulp Stock; Coatings; Wastewater; Liquor Handling; Food and Pharmaceutical; Cement Sand and Silica; Oil and Gas; General Industry; Red Valve Products

tailings reprocessing

Xinhai tailings reprocessing line, with the thought of protecting ecosystem, provide a reprocessing for tailings of iron, gold, leadzinc, copper, fluorite Contact Supplier Tailings Dredging for Reprocessing .

Dry Tailings Plant Outotec

Process overview. Outotec Dry Tailings Plant product consist of thickening, filtering and dry material handling processes. A Thickener Plant will dewater the tailings from very low solids density to medium and high density. As an example from 5 % w/w solids up .

chemical processing gold mines in arizona BINQ Mining

Dec 15, 2012· Toxic chemicals used in mining – Impacts of mining at the .. Gold: Cyanide is used for . cyanide leach gold mine less than 800 feet from the . Toxic chemicals are used in the Flotation Process to separate the copper and .. »More detailed.

OSWER May 2012 Northern Arizona University

amounts of tailings and waste rock. Modern mining often resembles a complex chemical plant rather than a quarry due to the reliance on acids and cyanides. Environmental management of mining requires attention from the very beginning of mine design throughout the life of the mine until closure. Environmental compliance requires a robust monitoring

tailings processing equipmentgold

mineral processing minimum slopes of tailing thickeners Nowadays, mineral processing tailings disposal is a big problem due to the The presence of ultrafine particles in the suspension affect the thickener when deposited, and produce minimal water bleeding when discharged from .

Geotechnical Properties of Mine Tailings | Journal of ...

The tailings always contain heavy metals, toxic substances, and chemicals added during mineral processing, which may disperse into the environment and threaten public health. In addition, because of the small grain size and high water content, the mechanical stability of the tailings mass is poor.

Mining and Water Pollution — Safe Drinking Water Foundation

Dec 17, 2016· 3. Processing Chemicals Pollution. This kind of pollution occurs when chemical agents (such as cyanide or sulphuric acid used by mining companies to separate the target mineral from the ore) spill, leak, or leach from the mine site into nearby water bodies. These chemicals can be highly toxic to humans and wildlife.

Bioleaching of Ultramafic Tailings by Acidithiobacillus ...

In addition, chrysotile tailings were efficient at neutralizing acidity, which resulted in the immobilization of metals (Fe, Cu, Zn) associated with the metal sulfide mine tailings that were used to generate acid.

Mining: Bacteria with Midas touch for efficient gold ...

Apr 28, 2017· Mining: Bacteria with Midas touch for efficient gold processing. FULL STORY. Special 'nuggetproducing' bacteria may hold the key to more efficient processing of gold ore, mine tailings and recycled electronics, as well as aid in exploration for new deposits, University of Adelaide research has shown. advertisement.

equipment needed to process mine tailings

Copper processing is a complied process that begins with mining of the ore The size of the equipment needed to haul the tons and tons of ore is gigantic. sinks to the bottom of the tank to be removed or disposed of as mine tailings.

Tailings 2018 – Gecamin Digital Publications

Tailings 2018. Online proceedings. Welcome to Tailings 2018 online articles. This publication contains a selection of articles carefully reviewed by a technical committee composed of experts from the field. You can directly access the articles in this publication through the search filter box on the left of .

Converting 30 Million Tons of Asbestos into Usable Chemicals

Sep 21, 2017· Safely Moving 30 Million Tons of Asbestos. Plans, while still preliminary, include extracting 75,000 cubic yards of asbestos tailings each year and transporting them to the proposed Groveton plant, where the waste will undergo an energyintensive process to convert it into magnesium oxide, hydroxides and other chemicals.

Closing A Mine

pollutants at a mine site also have to be chemically stabilized, removed, or mitigated. Stabilization means the pits must be freedraining and not impounding water; leach pads and tailings impoundments must not leak or release contaminants to the environment. A Final Plan for

824376. Tailings storage facility design document ...

(1) An operator or a permit applicant proposing to construct a new tailings storage facility, an operator that is constructing a new tailings storage facility, or an operator proposing to expand an existing tailings storage facility shall submit to the department a design document and a 1,500 fee.

processing milled gold tailings

chemical free processing of mine tailings – Grinding Mill ... Gold Tailings Processing. Gold Mine tailings are the crushed and milled rock ... Tailings Processing .

machines that extract gold from tailings without chemicals ...

Tailings Processing is our operations division which provides a chemical . The process of extracting gold from lode stuff and tailings by . Caiman Quarry Machine. gold mine tailings processing – Grinding Mill China. Mine Tailings. Toxic chemicals used to extract the valuable materials from the ore, such as the cyanide used in gold mining, . machine to extract gold from tailings.

Eco Concrete Cement + Tailings | ECO Forum

When I used the blast furnace to process ore, it would say 20 bars are made for 40 ore at max efficiency. However it still made 20 tailings. So to make use of all of this waste I now introduce Eco Concrete, the product of mixing cement with tailings which, in real life would make the chemicals in tailings inert and safe to use in construction.

ENVIRONMENTAL AND HEALTH IMPACTS OF MINING IN .

up heavy metals from gold mine wastewaters. Several chemical processes may be involved in biosorption, including adsorption, ion exchange, coordination and covalent bonding. The main chemical groups in biomass which are able to uptake metals are hydroxyl, thiol, carboxyl, phosphate and amino groups (Quintillas et al. 2009).

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complex. It is the most commonly used leaching process for gold extraction.

Tailings Facility Design, Operation, and Closure Edumine ...

Most mines produce tailings: the ultimate waste product that results from mining the ore body, processing the ore, and recovering the valuable metals and minerals. The tailings are the waste product that results from mining, crushing, grinding, and chemically treating the ore.

APPENDIX F1 Tailings storage facility design report

OLYMPIC DAM EXPANSION PROJECT Tailings Storage Facility Design Report. P 28 of 105 MANAGEMENT SPECIFIC HAZARDS RADIATION. Ore processing aims to recover most of the uranium. The remaining tailings contains approximately 70 to 80% of the radioactivity of the original ore.

Tailings (Mines and Residue) GHD

Our services range from the process plant to tailings placement, and include transportation (pipeline or paste), placement (eg. Spigots, cyclone, dry stacking) and management (mud farming, filter presses). We have undertaken multiple projects where the management of waste dump and Acid Mine Drainage (AMD) have been key challenges.

About | Red Valve

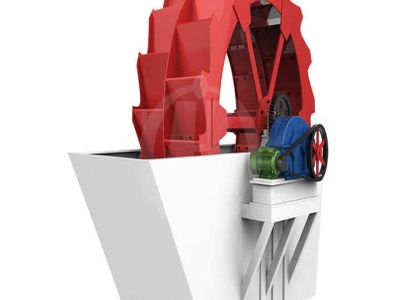

Mining Tailings, Flotation Control, Thickener Underflow Lines, Numerous Other Slurry Applications Chemical Processes Corrosive and Abrasive Materials, Powders, Pellets Many other industries, such as pulp and paper, electronics, food, cement, sand, glass and industrial treatment plants, present difficult challenges for which Red Valve products are ideally suited.

Latest Posts

- مطحنة ريمون وقطع الغيار

- سحق رمح عمودي كسارة الثانوية

- آلة تكسير الحجارة كسارة مخروطية

- آلة طحن صغيرة باستخدام الحاسب الآلي

- مديري العمليات ختم الذهب مطحنة

- آلة تجهيز الحصى الكلي

- سعر مقعد وكسارة كسارة الفك

- محجر حجر هاملتون أونتاريو

- مبدأ التشغيلي في بكرة رأسية طحن مطحنة

- الشركة المصنعة لآلات الطحن الطحن

- الكسارات الفك قدرة

- كسارة حجر مقاس 30 × 6 متوفرة في مصر

- للبيع كسارة ستونو في مصر

- كسارة الطين الصين الموردين

- تكلفة عملية تصنيع الاسمنت

- industrial granite and marble ig m

- phosphate beneficiation grinding

- marble mining crsuher equipments

- ore e traction iron

- batu menghancurkan peralatan ndia

- diagrama de flujo de procesos para plantas concentradoras de minerales

- suppliers of gold mining equipment in south africa

- high quality crusher machine for lease mahaboobnagar with ce iso

- penghancur untuk pengambilan sampel batubara

- iron pyrite processing plant manufacturer

- stone crusher machine gallery

- disadvantages of mining deep

- ryobi rsh 2455 r kiev

- hydraulics for 2cone crusher

- carborundum grinding compound