roasting pyrite conveyor

pyrite roasting an alternative to sulphur burning

Roasting of Pyrite Pyrite, or iron sulphide, is roasted in various types of furnaces, multiplehearth furnace, rotary kiln and fluid bed roaster, producing a gas with a somewhat lower sulphur dioxide content than the combustion gases from burning elemental sulphur.

Microwave roasting of ore

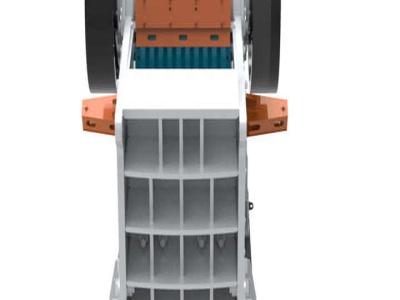

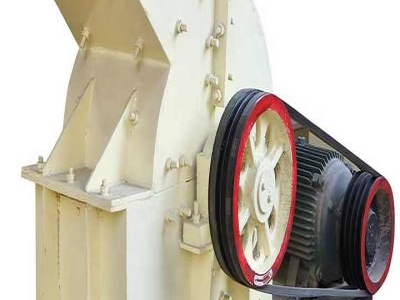

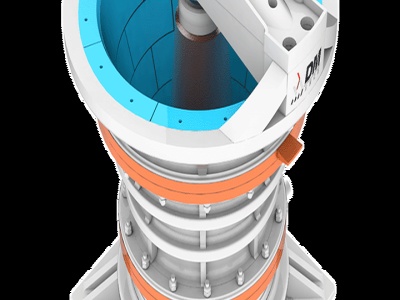

Crushers, Screen, washing, Feeder, conveyor for Microwave roasting of ore Microwave roasting of ore Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Microwave roasting of ore, quarry, aggregate, and different kinds of minerals.

Roasting Process Of Iron Ore

Roasting is a process of heating of sulfide ore to a high temperature in presence of air. It is a step of the processing of certain ores . More specifically, roasting is a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s).

roasting iron ore

161. Roasting of Iron Pyrite Ore 1 An iron pyrite ore containing % FeS 2 and % gangue (inert dirt, rock, etc.) is roasted with an amunt equal to 200%. Contact Supplier

Evaluation of heavy metal bioavailability from Almagrera ...

Since the roasting pyrite wastes are composed of a relatively inert iron oxide (Sáez et al., 2005), this work focusses on the sulphide tailing dam which wastes are similar in origin and characteristics to those collapsed in the Aznalcóllar mining district, and therefore, the potential harmful impact on the environment that would cause the waste spillage is already known worldwide (, LópezPamo et .

PilotScale Testing of an Integrated Circuit for the ...

• Roasting at an optimum temperature of 500 – 750 O C causes: • Decomposition of rare earth minerals in the presence of activating reactants • Decomposition of clays • Fuel is provided by the presence of carbonaceous material. • Advantages include: • Improved REE recovery • Reduced acid consumption • Increased leaching kinetics

processing pyrite gold

The dissolution of gold from roasted pyrite concentrates SAIMM A of the dissolution of gold from a pyrite concentrate and from various calcines is reported. ... the roasting process, a mixture of these products might.

AeroRoast™ Dry Roaster

A modular design option allows the AeroRoast to be shipped with the conveyor bed installed, reducing installation time and cost onsite. Validated kill step for peanuts. The AeroRoast is capable of being validated as a kill step in the roasting of peanuts due to its .

roasting production ore

Roasting (metallurgy) Roasting is a process of heating of sulphide ore to a high temperature in presence of air. It is a step of the processing of certain ores . More specifically, roasting is a metallurgical process involving gasu2013solid reactions at elevated temperatures with the .

Roasting Of Iron Ore For Ugradation

roasting of iron ore for ugradation stone crusher plant . Effect of magnetizing roasting on removal of iron from bauxite ore for refractory uses, . Get Price And Support Online; roasting of iron ore for ugradation stone crusher . several advantages in the upgradation process including .

mining pyrite raymond

Pyrite and Coal Mining. Sulfur occurs in coal in three different forms 1) organic sulfur, 2) sulfate minerals, and 3) sulfide minerals (mostly pyrite with minor amounts of marcasite). When the coal is burned, these forms of sulfur are converted into sulfur dioxide gas and contribute to air pollution and acid rain unless they are removed from the emissions.

Guidelines for Validation of Dry Roasting Processes

Dry (hot air) roasting is a thermal process used by the almond industry. A dry roast can be achieved via a continuous conveyor roaster or rotary roaster. The continuous conveyor roaster can be singlestage or have multiplestages with a variety of temperature controls. Common temperatures used for hot air roasting range from 265°F to 310°F.

Process mineralogy of roasted pyrite and arsenopyrite ...

Process mineralogical techniques can provide useful information on the mineralogy and textures shown by pyrite and arsenopyrite particles that have been roasted to enhance extraction of gold from refractory gold ores.

roasted gold ore

Roasting is a process of heating of sulfide ore to a high temperature in presence of air. It is a step of the processing of certain specifically, roasting is a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s).

How to control fugitive dust emission in cement plant?

Accumulated particulate dust is deposited into a hopper, dust bin or screw conveyor at the base of the collector.

roasted pyrite

ChE 322N Lesson 9 (Roasting of Pyrite Ores).docx Free download as Word Doc How many pounds of FeS2 are lost in the cinder per 100 pound of pyrites roasted. Contact Supplier Pyrite roasting Mass balance with chemical reaction. Mar 15, 2015 · 1. The problem statement, all variables and given/known data A certain pyrite ore contains 85% of ...

Arsenopyrite an overview | ScienceDirect Topics

In the case of mesothermal pyritic gold ores, pyrite and arsenopyrite are sufficiently coarse grained, which allows for good liberation at modest grind fineness (P 80 of 75–120 μm) and results in highgrade concentrates with good recoveries. In some of these ores, submicroscopic gold is exclusively carried by arsenopyrite, which makes separation enticing from the barren pyrite (Donlin Creek ...

Latest Posts

- مركز طحن طحن عمودي

- خام الحديد كسارات من المملكة العربية السعودية

- مطحنة ذهب السعودية

- تستخدم إلى حد ما محجر كسارة

- محطم حدة الكريات المملكة العربية السعودية

- 50 مكينة كسارة حديد يوميا

- تستخدم ريموند مطحنة الأسطوانة في المملكة العربية السعودية

- ماكينات صنفرة السودان

- آلة حاسبة لنفايات السيور الناقلة

- كسارات الحجارة في السودان للبيع

- البازلت روك للبيع نيوزيلندا

- حجم الشاشة شبكة كسارة الحجر

- الاتصال كسارات الحجر النبات في pathankot البنجاب

- آلة صنع الرمل ذروة

- كسارة فحم صغيرة للبيع 25 طن في اليوم الواحد

- rc keene rock crusher

- wet sieving equipment

- screen and crusher plant south africa

- gold prospecting equipment jaw crusher

- crusher 150 1200

- sand maker machine for copper ore made in russia

- issues involved in the waste from froth flotation

- cone crusher jaw machinery part for

- international ballast rock quarry

- mobile iron ore impact crusher manufacturer indonesia

- crusher 2006 models concrusher detials

- granite jaw crusher in england

- sand dryer overview

- fuction of benefaction cyclone in the plant

- sand and gravel vibrating screen