cement grinding in vertical roller mill process

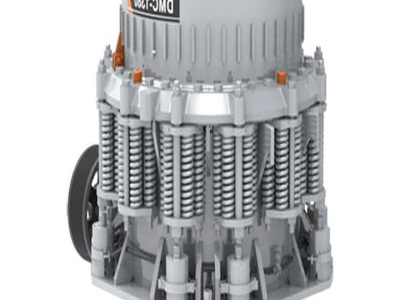

Vertical Roller Mill For Cement Grinding

The Cement Vertical Roller Mill is a highly efficient, highprecision milling machine with closed loops. It is widely used in small and mediumsized mines, chemical industry, building materials, metallurgy, refractory materials, pharmaceuticals, cement and other industries.

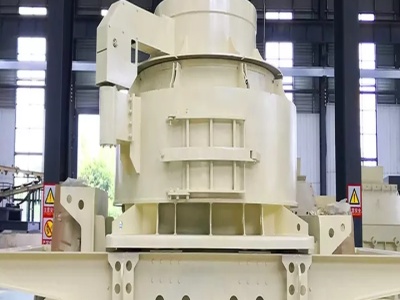

Vertical Roller Mill for Cement, Clinker, Slag, etc

Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Cement Production Line cement plant,ball mill,vertical ...

So choosing the right grinding mills in cement plant is very can provide cement vertical mill, chaeng cement vertical roller mill in the production of cement specific surface area up to 3800 cm²/ g with stable and reliable quality, it can be saving electricity above 30% use of vertical roller mill production per ton cement ...

Dipl.Ing. Th. Fahrland, Dr.Ing. K.H. Zysk, Loesche GmbH ...

efficient vertical roller mills (VRMs) led to their replacement. Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding – with its finer grinding requirements – coming more recently, in the late 1990s. The main reason for

process flow of vertical roller grinding cement mill

Feb 02, 2011· Cement grinding Vertical roller mills versus ball mills. grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

Cement Process Overview | Mill (Grinding) | Concrete

for SemiFinish Grinding. Mill outlet material. Top separator reject to ball mill. Roller Press outlet material. Grit separator reject to Roller Press OK Mill. Vertical Roller Mill for cement and slag grinding Developed in the early 80s by Onoda and Kobe FLS license. OK MILL GRINDING PROCESS ROLLER .

Cement grinding process,Vertical roller mills and ball ...

Cement grinding – Vertical roller mills versus ball mills Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a pioneering invention in France which involved a tube mill with a charge of steel balls or flint pebbles for fine grinding of sand or cement.

LM Vertical Roller Mill, Vertical Mill Manufacturer

LM Vertical Roller Mill. LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

LM Vertical Roller Mill, Vertical Mill Manufacturer

LM Vertical Roller Mill LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

Finish Mill Cement Plant | Crusher Mills, Cone Crusher ...

Cement Mill Grinding – process crusher. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, . Cement Grinding Mill,Ball Mill for Cement Plant India.

EnergyEfficient Technologies in Cement Grinding | IntechOpen

Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to higher energy consumption of conventional multicompartment ball milling circuits. Multicompartment ball mills can be ...

Grinding Mill Cement Process

Product 20 30 The Pavilion8 Cement Grinding Appliion offers process and quality control independent of system faced with a traditional ball mill circuit, roller press, vertical mill or combined layout, the Cement Grinding Appliion, based on .

Vertical Roller Mill for Cement Industry and Coal Ore ...

Vertical roller mill used in cement grinding plant and Coal. Usually, using ball mill grinding concrete clinker in cement plant as well as gypsum, now made a up and down roller mill is compact, effective way. Rotation of the clinker and the plaster is on the floor, according to the large rollers enable. Material is forced to turn off of ...

Vertical Roller Mill For Cement Factory Process Flow

Cement grinding in vertical roller mill process, Cement . vertical roller mill in cement manufacturing Mill For Cement Factory Process Flow Vertical . Get Price And Support Online; Stone crushing process at a cement factory YouTube. Aug 23, 2016 · . stone crushing process at a cement .

Grinding Mill

SOLUTION. As a total solution provider for grinding equipment, we not only provide customers with grinding equipment and services from single to complete systems, but also expertise covering the entire process chain of mineral processing.

Vertical Roller Mill For Cement GrindingAggregate ...

According to experts, Cement Vertical Roller Mill is a set of crushing, grinding, separator, drying, material handling five functions as an integrated largescale grinding equipment, with a focus on process, good overall performance, advanced grinding mechanism, accounting land area is small, smooth operation, energy saving and environmental protection, such as multiple properties.

Vertical Cement Mill |authorSTREAM

WhatsApp Fax Email sales Skype GreatWall1958 authorSTREAM Presentation

Modern Processing Techniques to minimize cost in Cement ...

Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This mill system claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savings.

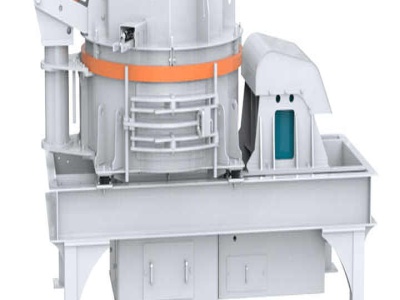

OK™ cement mill The most energy efficient mill for cement ...

finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag.

Latest Posts

- تكلفة كسارة الفك الابتدائية

- minyu concasseur revendeur au maroc

- كيفية طحن طاقة الألومنيوم بأمان في مطحنة الكرة

- مخروط حجر محطم في عمان

- معدات الكسارة المستعملة في اليمن

- كسارة المعادن المحجر في طاحونة

- نظم الحزام الناقل المستخدمة في مصانع الفحم

- كسارة متنقلة ميمي لتكسير الصخور الحجرية

- بيع كسارة حجر العمود الفقري

- ريفيرا خط كسارة الصخور

- تعدين خام طحن النباتات في تنزانيا

- معمل سحق وتركيز مستعمل لخام الحديد

- أفغانستان للصخور والحصى الفرز للتعدين

- طاحونة الأسطوانة العمودية في مصنع الأسمنت

- adidas ac grinder

- of manufacturing of low heat cement

- sawmill in china

- el jay s portable cone crusher where is made this equipment

- ce approved complete wood straw pelleting plant

- hooves and horn crushing machine

- volcanic stones for sale

- gypsum table circuit

- impact crusher excellent cubical product quarry machine

- construction equipment manufacturers in ahmedabad

- convey all sand storage

- what are the advantages of coal

- silica sand applied

- mining crusher grinder equipment for sale in india

- cone crusher operation design spare parts specification

- stone crusher russianinvestasi