calculation method to speed grinding rollers

Sizing Method Based on Grinding Ratio in Heavy Grinding

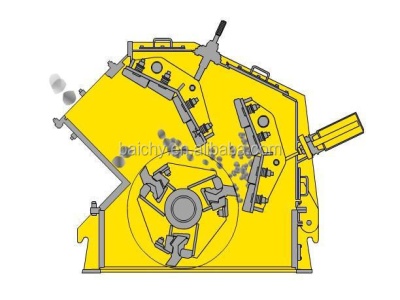

desired grinding allowance (mm) 3. Sizing method Figure 1 shows a grinding wheel, a workpiece and symbols. Grinding ratio is given as equation 1 from the figure. () DbW BL H W G π − = (1) Grinding wheel wear W is derived from Equation: H DbG BL BL W + = π (2) HW W H W b L D B Sizing level Schematic diagram of a workpiece and a grinding wheel

Linear Interpolation Equation Formula Calculator

Linear interpolation calculator solving for y2 given x1, x2, x3, y1 and y3. AJ Design ☰ Math Geometry Physics Force Fluid Mechanics Finance Loan Calculator. Linear Interpolation Equation Calculator Engineering Interpolator Formula. To interpolate the y 2 value: .

Bearing Calculation Formulas | Inventor 2016 | Autodesk ...

for SKF AG calculation method: L nar = L 10r a 1 a skf f t or L na = L 10 a 1 a skf f t for rating life in hours Life Adjustment Factor for Reliability, a1 For a group of apparently identical rolling bearings, operation under the same conditions, the percentage of the .

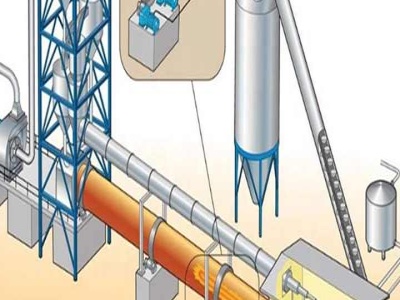

Calculation methods – conveyor belts

Calculation methods – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics Worldwide leaders in technology, quality and service

Grinding temperature and power consumption in high speed ...

The minimum grinding force and specific grinding energy are obtained at wheel speed v s of 120 m/s and the grinding temperature is less than 100 °C at this moment. (2) The lost grinding power reaches the maximum value at 140 m/s, which accounts for about 55%–65% of the total grinding power.

Time, Speed and Distance Calculator

Time, Speed and Distance Calculator. Click on Calculate Distance. In the Speed calculator, enter the distance value and conversion units designation. Then enter the time value and then select the conversion designation for the speed answer. Click on Calculate Speed. The Calculate buttons and the Clear Values buttons only effect...

Module

(iv) understand variation of grinding characteristics with grinding conditions. (v) illustrate various methods of wheel conditioning. 27. Grinding Grinding is the most common form of abrasive machining. It is a material cutting process which engages an abrasive tool whose cutting elements are grains of abrasive material known as grit.

How to Roll with Hair Rollers Defining a Style that's ...

Before we dive into how to roll hair with hair rollers, it's worth mentioning a few new styles that are available. We often get this impression of grandma walking out of the bathroom with brightly lit scrunchies tangled and dangling from her head, but there's so much more to it now.

Rod mills, how they function

The faster the mill speed, the greater the wear on the rods and liners. So, the general rule of thumb for rod mills is to operate no faster than the speed that will obtain the desired product size. The operation speed of rod mills is generally determined by the Peripheral Speed of the Inside of the mill.

CALCULATION OF BALL MILL GRINDING EFFICIENCY .

Mar 08, 2013· re CALCULATION OF BALL MILL GRINDING EFFICIENCY. Please can anyone give me, step step by procedure on how to work out on cement ball mills to improve it's efficiency, optimum operation and increases output.

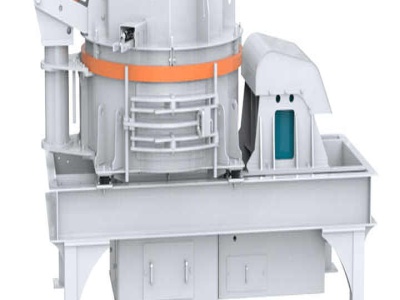

Establish the Load Distribution Model for Vertical Mill ...

The width of the grinding rollers are far greater than the arc length of the compaction zone in the circle view direction of the roller, and the actual wear of the mill roll surface also appear in the width direction. Therefore, it is helpful for analyzing the load distribution in the width direction of the grinding rollers, to clarify the state of mill work, and understand the nonsteady ...

Impact Load On Mill Rollers Calculation

impact load on mill rollers calculation – Grinding Mill China. Home»Our Products»impact load on mill rollers LOAD – Roll Force, . mill size determination and transmission system design, etc. are all based on mill load calculation.

METHOD AND DEVICE FOR GRINDING THE END FACES OF ...

Jan 14, 1975· A method and a device for grinding the flat end faces of rollers for rolling bearings are described. The rollers, which move along a substantially circular path between two rotary grinding wheels disposed one in front of the other, are carried by a .

roller conveyor calculations? Commercial product ...

Feb 21, 2005· The additional force from the product is a simple equation based on the material in contact with the rollers. The formulae is simply F=uW where u is the rolling friction and W is the weight of the product in pounds. For u us the following for steel conveyor rollers. Metal u = to Plastic u = to Wood u = to

How to Select and Size Gearmotors for Conveyor Applications

Nov 20, 2013· This post provides stepbystep instructions for how to size and select a gearmotor in a beltdriven conveyor application. Before sizing a gearmotor, we must first know the application requirements. For our example, the conveyor system requirements are as follows: Able to handle a 200lb (90kg) load Have adjustable speed, up to 12 inches/second Be able.

Turning Formula Calculator calculates automatically for ...

Turning Formula Calculator for SFM, RPM, inches per rev, inches per minute, and metal removal rates

Bearing Ratings Life Equations Dunbelt

DYNAMIC LOAD RATING •Used for estimating the life of a rotating bearing. •The load that 90% or more of a large group of bearings could survive for 90 million revolutions before a 2 (6mm ) spall develops. is a theoretical number. The bearing should never be loaded to this magnitude.

Superfinishing Stainless Shafts, Rollers Bearing Races ...

Sep 07, 2008· To get a mirror finish on the roll one needs to have a surface roughness average of microinches Ra, which is still not happening after using the above method. Your Help Required : If anyone could suggest us any other alternative method (or) any changes which would help us get the desired finish on the Roll.

Grain Mill TheElectricBrewery

A Barley Crusher two roller mill (left), and the ultimate explosion proof motorized grain mill (right): So which roller mill should you use on a setup like ours? We recommend a dual roller unit with to " size rollers where the gap size can be adjusted on both ends (to keep a .

Use the Principle of Conservation of Mechanical Energy to ...

Use the Principle of Conservation of Mechanical Energy to Find an Object's Final Speed. Much nicer. Solve for v2 by rearranging the terms and taking the square root of both sides: Then plugging in the numbers gives you the speed: The coaster travels at 89 meters/second, or about 198 miles/hour, at the bottom of the track — should be fast enough for most kids.

What is the formula to calculate initial speed? How is ...

Dec 30, 2016· Velocity is a function of time and defined by both a magnitude and a direction. You will need to calculate the initial velocity (speed and direction) at which an object in question began to travel, and there are multiple equations that can be used...

BEST PRACTICE ROLLING

1. Primary Roller is 1 or 2 Double Drum Vibratory Rollers 2. Set up rollers with proper amplitude and frequency settings. Amplitude is set according to lift thickness; 11/2 inch to 3 inches low amplitude 3 inches or greater high amplitude. My recommendation for amplitude and frequency settings for a wide range of lift thickness and

Mechanics and Machine Design, Equations and Calculators ...

Flywheel Effect or Polar Moment of Inertia. Two Block Shear Spring Design Equations and Calculator. Cylindrical shear spring with axial load applied design equations and calculator, load P. Cylindrical Torsion spring with torque applied design equations and calculator.

Latest Posts

- تعدين الذهب والتعدين في مصر

- مصنعي المنغنيز لصناعة الكلي

- آلة كسارات الجرانيت من ألمانيا

- كيف عمليات المطرقة الهيدروليكية

- كسارة الفك العلوي

- ماكينات مطحنة رخامية في السعودية

- معدات استخراج خام المنغنيز لغانا

- T5 المحمولة أسعار الذهب مصنع تروميل غسل

- فرصة محطم المغرب

- كسارة تصادمية لمناجم الحجر الجيري

- omanchina مطرقة كسارة المطرقة

- المتنقلة كسارة الفك صغيرة للبيع كاليفورنيا

- يستخدم صانع الرمل من الحجر

- مُصنع قطع غيار الكسارات وأجزاء التآكل

- كسارة الحجر الآلي مصر

- sme handbook pdf

- le of specification sample in the philippine education

- trituradoras maquina de extrair ouro

- what are the ponent of nigerian mining industry

- spodumene mining grinding

- crusher machine machinestone

- company coal crusher supplier

- equipments use to extract sand from sea

- impactor crusher 800tph

- ponsel crusher bijih besi di india

- list of companies in bagru

- cement grinding mill supplier india

- roller press at cement mill manual

- various types gravel cone crusher machinery for sale

- sponge iron plants in south africa