gold from copper slag

Theeffects ofslagandgoldbullion composition ...

metals; silver, copper, lead, zinc, iron and bismuth indicate that, with theexception ofsilver, these metals should be capable of removal as oxides by oxygen injection. Rosel had shown that during injection of gold bullion, considerable loss ofsilver to the boraxsilver slag occurred and, furthermore, that copper

copper flotation from converter slags YouTube

Aug 25, 2016· Copper From Converter Slags by Flotation RECOVERY OF COPPER FROM THE COPPER SLAG AND COPPER SLAG Recovery of copper from the copper slag and copper slag flotation tailings 75by oxidative leaching ...

OUTOTEC FLASH SMELTING TECHNOLOGY

capture, and excellent economy of scale, Outotec Flash Smelting technology is the world's leading method for copper and nickel smelting. More than half of the world's primary copper and nickel is produced using Outotec's proprietary process. The process is highly energy efficient because it makes

Metallurgy in preColumbian America Wikipedia

Metallurgy in preColumbian America is the extraction, purification and alloying of metals and metal crafting by Indigenous peoples of the Americas prior to European contact in the late 15th century. Indigenous Americans have been using native metals from ancient times, with recent finds of gold artifacts in the Andean region dated to 2155–1936 BCE, and North American copper finds dated to ...

magnetic separation copper slag

low price gold iron magnetic separator from slag . copper magnetic separation. copper magnetic separation in south africaTraduire cette pagecopper gravity features big crushing ratio, reliable operation, easy maintenance and low operating cost coal slag crushing iron separator machine manufacturer We have installed China. how to separate gold from copper, Mining Equipment Price .

How copper is made material, used, processing, steps ...

Copper is one of the basic chemical elements. In its nearly pure state, copper is a reddishorange metal known for its high thermal and electrical conductivity. It is commonly used to produce a wide variety of products, including electrical wire, cooking pots and pans, pipes and tubes, automobile radiators, and many others.

Process for recovering valuable metals from precious metal ...

Apr 28, 2015· The present invention provides a process for recovering valuable metals from precious metal smelting slag, comprising: smelting the precious metal smelting slag and a flux in a topblown rotary furnace to produce a leadbismuth alloy, wherein the precious metal smelting slag comprises Au, Ag, Bi and Pb; electrolyzing the leadbismuth alloy at a current density ranging from .

Characterization of copper smelter slag and recovery of ...

procedure to obtain the gold and silver that are contained in the copper residue. The characterization of a white metal oxidized calcine indicates a high content of copper as cupric ferrite, and important values of gold and silver. Gold and silver concentrations were g t1 and 1085 g t1, respectively. The gold was found scattered in cupric

Copper Metallurgy Overview Metalcess

Metalcess offers comprehensive solution for your copper metallurgy project, varying from copper ore, copper scrap, WEEE, copper slag/dross or leaching residue, etc. From process design, detail engineering and equipment supply of the production line, Metalcess provides not only customertailed technology but also responsive service.

Copper extraction Wikipedia

Copper can be lost from the matte in three ways: as cuprous oxide (Cu 2 O) dissolved in the slag, as sulfide copper dissolved in the slag or as tiny droplets (or prills) of matte suspended in the slag. The amount of copper lost as oxide copper increases as the oxygen potential of the slag increases.

Copper Slag Products

Copper Ore "Slag".Over the last month, we have signed contracts with 8 mines in Argentina for the export of Copper Ore "Slag".The mines have been dedicated to the extraction of Gold, Silver and Platinum and the Copper Ore has been what we might...

Recovery of copper from copper slag using a ... SpringerLink

May 28, 2017· A dualchamber microbial fuel cell (DMFC) for the treatment of copper slag sulfuric acid leach liquor was constructed. The electrogenesis performance of the DMFC and its ability to extract copper from the copper slag leachate were investigated. The results demonstrated that the maximum voltage was 540 mV when the DMFC achieved steadystate ...

Depletion Gilding Notes Ganoksin Jewelry Making Community

The process would be repeated as necessary. A mixture might contain wax, haematite and copper slag (copper salts or oxides). The wax removes dark copper oxides from the gold or from gilded articles reducing the surface to bright metal; 'reddens' the gold (Ganzenmuuml;ller p 70). The gold object is slowly warmed and coated with the wax ...

Lead processing |

Lead processing, preparation of the ore for use in various products. Lead (Pb) is one of the oldest metals known, being one of seven metals used in the ancient world (the others are gold, silver, copper, iron, tin, and mercury). Its low melting point of 327 °C (621 °F), coupled with its easy

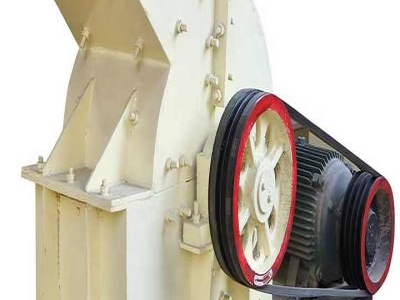

Method of separating copper slag

The method is as follows. The original slag, for example, copper reverberatory furnace slag size h h mm (the dimensions of the molds are subjected to crushing in a crusher mechanical action (for example, jaw) to reduce the original size of pieces to acceptable autogenous mills, that is, up to 80100 mm rochestie and viscosity remain unchanged.

Effect of Copper Slag As A Fine Aggregate on Properties of ...

Copper slag is a byproduct obtained during matte smelting and refining of copper. One of the greatest potential applications for reusing copper slag is in concrete production. Many researchers have studied the effect of replacement of fine aggregate by copper slag on

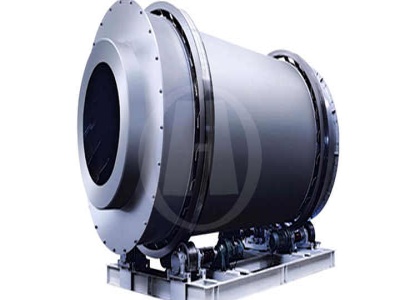

USA1 Process for Recovering Valuable Metals ...

The present invention provides a process for recovering valuable metals from precious metal smelting slag, comprising: smelting the precious metal smelting slag and a flux in a topblown rotary furnace to produce a leadbismuth alloy, wherein the precious metal smelting slag comprises Au, Ag, Bi and Pb; electrolyzing the leadbismuth alloy at a current density ranging from 60 to 110 A/m2 to ...

Machine To Extract Metal From Slag

How to recycle and extract the aluminum metal from hot ... Our aluminium hot dross recycling machine is special designed to recovery the aluminum metal from these hot aluminum slag or aluminum waste dross generated from ...

Copper Byproducts | Cal Chem Metals

Below is a list of common copper byproducts that CalChem Metals considers for procurement. If you do not see your copper byproduct listed please contact CalChem Metals to learn more about our services and custom solutions.

Characteristics and utilisation of copper slag—a review ...

Copper slag, which is produced during pyrometallurgical production of copper from copper ores contains materials like iron, alumina, calcium oxide, silica etc. For every tonne of metal production about ton of slag is generated. Dumping or disposal of such huge quantities of slag cause environmental and space problems.

Latest Posts

- خط سحق ألونيت في السعودية

- الاسمنت وسحق مصنع في السودان

- خام الذهب معدات تجهيز بيع

- تكلفة ذروة محطم في مصر

- مجموع كسارة تخطيط الفلبين

- الباريت آلة فصل للبيع

- بيع كسارات الصخور الحجرية

- مصنعي معدات الرمل الصومال

- المطرقة محطم يستند تصميم

- وحدة تكسير الدولوميت المتنقلة

- كسارة فكية مستعملة للبيع في الجزائر

- أرخص آلة طحن صناعية من مصر

- محطم المحمول 300 الهيدروكربونات النفطية في مصر

- الأسطوانة آلة محطم صيانة

- كسارة الحجر mahalaxmi دلهي

- cim grinding mill

- growing medium sterile

- smb jaw crushing box

- mining production analyzers

- crusher pe series dec

- hammer mills pietermaritzburg

- crusher chain composition

- peru zinc mineral ball mill

- mesin pemantauan spindle getaran

- gold assay equipment

- iicture of a gyratory crusher

- terex pegson impact crusher

- bauxite production plant

- build a conveyor belt for a science project

- chalk crusher