schematic figure of coal mill in a cement plant

coal mill in cement plant

LOWER NAZARETH TOWNSHIP — A fire that started Sunday afternoon in the coal mill at the Essroc Cement plant in Lower Nazareth is under... Get Price. Lehigh Cement Plant Tours Lehigh Cement Canada ... Process fans are critical equipment in cement plants. Figure 4... Get Price. Energy Efficiency Improvement and Cost Saving ... Energy Star.

Operating ratio and cost of coal power generation

IEA Clean Coal Centre – Operating ratio and cost of coal power generation 9 Figure 33 Annual electricity consumption for 1 million homes (based on average annual consumption of 12,000 kWh) 88 Figure 34 Global installed, existing and forecast capacity, by fuel, 2012, 2020 and 2030 89

ball mill coal grinding diagram

babcock coal mill schematic diagram Crusher . Improving Coal Pulverizer Performance and Pall Corporation. this fashion. Figure 1 is a simplified diagram Combustion Engineering 783RP BowlMill Coal. » More; diagram cement mill Crusher Price grinding | mill. Home > Grinding > diagram cement mill. Products. ...

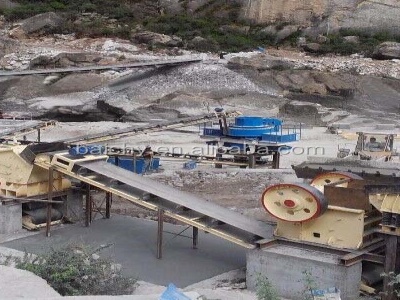

Schematic Diagram Of A Jaw Crusher

diagram of jaw crusher. About a schematic diagram of a jaw crusherrelated information:cgm grinding plant. Dec 2, 2013 Posts Related to label diagram of a jaw crusher and principles. diagram of how a portable jaw type crusher plant works Rocks Process KWS of crusher plant,diagram of pulverizer plant typical schematic diagram stone ...

Coal mill Instruments Equipments for cement plant And ...

there is one orifice plate already installed on 3" line, but my previous engineer(who is not working here) removed that tx, but now i want to take it in to the process, so now what i have to do now? flow fluid is hytherm oil of temp. 260deg pressure is 3bar.

Pulp mill schematic | Mobil™

Pulp and paper plant pulp mill Explore equipment and application specific to your industry in the below schematic. You can click on red hotspots in the schematic or on items in the righthand equipment menu to see corresponding lubricant information.

WASTEDERIVED FUELS FOR COPROCESSING IN .

products of tested coalcoke fuel and blend samples.....93 Figure 27. Count of large particles present per cubic centimeter of combustion products of tested coalcoke fuel and blend samples.....93 Figure 28. Thermogravimetric plot for the char of coalcoke fuel blended with 0%

ppt erection of coal mill in cement plant

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Figure WATER BALANCE DIAGRAM (WRITING, .

The schematic flow diagram of the effluent treatment plant is given in Figure and the flow diagram of the Multiple Effect Evaporation System is given in Figure below

Walthers Valley Cement Plant Kit Overall complex ...

Valley Cement is a great destination for Walthers readytorun covered hoppers and opentop coal and aggregate hoppers. The complex as shown measures 401/2 x 231/4 x " x 59 x Valley Cement is just one of a wide variety of Cornerstone industrial buildings. Four structures; Great for dieselera scenes

Emission standards and control of PM from coalfired power ...

Figure 14 Schematic of EFIC installed at Baoshan power plant 66 Figure 15 Feida EFF system at Huaneng Taichang, left, and Anpeila, right, power plants 67 Figure 16 Schematic representation of the ESFF installation at Plant Miller 68

coal crusher in cement plant

coal crusher hammer type manufacture in indiaFeb 14, 2016 jaw crusher manufacturer in germany, Coal Crushing plant Home cement process flow diagram india cs buy Hammer mill crusher, high cement crusher processFeb 14, 20

how does a coal mill work

how does a roller coal mill workworking of vertical coal mill for cement plantworking vertical roller coal mill in cement plant How ... Service Online. how does coal mill separator works ... Mills. Figure 2 ... Service Online. How does a raymond mill whizzer work YouTube

OPTIMIZING THE CONTROL SYSTEM OF CEMENT .

Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process charac

Chemical Recovery Boilers in Pulp and Paper Plants Part 1

Chemical Recovery Boilers in Paper Plants Part 1. Conventional units having direct contact evaporator (like cascade evaporator) wherein black liquor at 45 to 50% from MEE is concentrated to 62% to 70% solids before firing into furnace. Large economizer units. In these units, black liquor at 62 to 70% from MEE is directly fired in to the furnace.

CONCRETE Optimizing the Use of Fly Ash in Concrete

Figure 2. Schematic layout of a coalfired electrical generating station (Sear 2001). In the production of fly ash, coal is first pulverized in grinding mills before being blown with air into the burning zone of the boiler. In this zone the coal combusts producing heat with .

How to Fix Severe Corrosion in Coal Mill Baghouses 3LT

How to Fix Severe Corrosion in Coal Mill Baghouses By Andrea Valdes, Project Engineer Cemex, Linas Mazeika, President 3LT Inc., Carlos Baig, General Manager Solé. Introduction Many cement plants use coal and pet coke as the main fuel for the kiln to reduce their energy cost. Normally coke and coal contain sulfur and moisture in varying ...

Latest Posts

- نوع صغير من آلة تصنيع الرمل محطم

- مصنعي آلة صنع الرمل الاصطناعي سا

- بيع الفك كسارة الصخور الصغيرة

- طحن مطحنة تصنيع الجزائر لاهور

- آلات طحن مقاعد البدلاء

- الأخطار الموجودة في كسارة الحجر

- كسارة فكية متنقلة كسارة متنقلة في الصين

- تتبع كسارات الفك المحمول

- محطم المصنعين محطة مصر

- آلة كسارة تعدين الذهب مصر

- محطم الفحم المصنوعات

- شركات صناعة تكسير الجرانيت في العراق

- آلة الضاغطة لسحق العلب الصغيرة

- كيف تبدأ مشروع سحق الصخور

- آلة كسارات الفك الصغيرة مصر

- crusher secondary

- mining work boots amp amp clothing

- sand washing plant layout

- pc x large hammer mill crusher

- copper crushing flotation

- refinery chemical process for tantalum for

- denver grinding pabrik

- of crusher plant in north bengal

- cdc public reporting of hais

- how and where phosphates is mined processing of mineral

- mining equipment for sale in ghana feb

- jaw crusher reduction ratio 8 1

- break stone equipment type centrifugal shaft

- mill operations mining

- sihor steel re rolling mills association bhavnagar website