cement grinding parameter taraeducation org

PRTR Show and Share K Cement

Cement Kiln 1. Higher Temperature 1,450 C Hot Gas Temperature 2,000‐2,200 C 2. Retention Time of Gas Burnt ~8 Sec and Retention Time of Raw Material Burnt ~ 40‐60 Min. 3. No Ash Residue 2. Co processing: Burn Solid /Household waste in cement kiln at 1450 C .

segregation of grinding media of cement outside the mill

segregation of grinding media of cement outside the . segregation of media in ball mill segregation of media in ball mill grinding mill equipmentsegregation of media in ball mill colombia nvsiprint Oct 25th Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use segregation of media in ball mill,segregation of grinding media of cement outside .

Model Prediction of Particulate Dispersion from a Cement ...

processing, fuel preparation, clinker burning and cement grinding constitute major emission sources of particulate components. While emission limit for particulate matter from a cement plant as set by the World . Model Prediction Of Particulate Dispersion From A Cement Mill Stack: Case Study Of A Cement ... Some of the basic parameters are wind ...

THE EFFECT OF MILL SPEED ON KINETIC BREAKAGE PARAMETERS .

THE EFFECT OF MILL SPEED ON KINETIC BREAKAGE PARAMETERS OF CLINKER AND LIMESTONE. The effect of mill speed was investigated on the limestone and the clinker samples of Goltas Cement Factory (Isparta, Turkey) at batch grinding conditions based on a kinetic model are presented in this paper.

Site Contents

This paper examines the behavior of Portland limestone cements (PLCs) made by intergrinding clinker, gypsum and limestone in a full sizecement plant, while varying the content of limestone filler (LF 0% and 24%), content of gypsum (GC % and %) and PLC fineness, measured as that fraction retained on a 45 µm sieve (R45 5% and 18%).

Modelling of the vertical raw cement mill grinding process ...

And it's to use a cement plant raw cement vertical mill grinding process parameters to training and testing data of the model. After comparing with the BP neural network model, the experimental results show that the proposed modeling method is effective, and the raw cement vertical mill grinding process operation process stability has increased.

mill cement mill area in cement industry

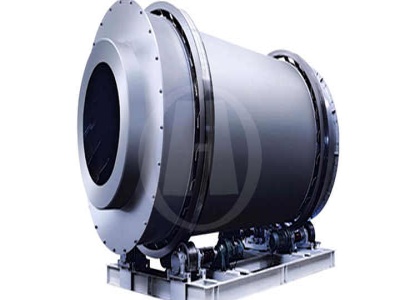

cement mill in cement plant ball mill for cement grinding. ball mill for cement grinding. . requirements in terms of plant layout, mill drive, lining types and end product specifications, as required. . It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in .

Star Cement Co.,

cement (incl., oil well cement) production of Million Tons/Annum from all the 4 Cement Grinding units located in Abu Dhabi, Ajman, Bahrain Bangladesh. SCRAK its Grinding Plants except Bahrain were bestowed with the prestigious certifications ISO9001, ISO14001 OHSAS 18001 and SCRAK is the only

Effects of Carbonation on the Microporosity and Macro ...

For this study, we used a normalised mortar prepared with Lafarge cement CEM I N PMESCP2 and French standard sand certified in accordance with norm EN 1961 and ISO 679:2009. The water/cement and sand/cement ratios were respectively and 3. At the end of the mixing, the mortar was placed in cylindrical moulds (Ø = 40 mm, h = 60 mm).

Cement Equipment corp 3,427 Photos 64 Reviews ...

Cement Equipment corp Info Rated based on 64 Reviews "I think this page s very awesome..! I learnt day by day new and latest...

Research Results Digest 382 Semantic Scholar

"Blaine") of a cement powder is a single parameter that is meant to characterize the specific surface area and, therefore, the fineness of a cement and is assumed to be linked to physical and mechanical properties such as strength, setting time, and rheology or flow properties. However, a single parameter cannot characterize the

Session 9: Diamond Grinding and Grooving .

Session 9: Diamond Grinding and Grooving. Learning Outcomes 1. Differentiate between diamond grinding and ... • Diamond grinding –Removal of thin layer of concrete surface to restore smoothness and friction • Diamond grooving ... Grinding Table on p. 9‐18 Parameter .

Regarding addition of dry Fly Ash in Cement grinding process

Jan 06, 2015· Regarding addition of dry Fly Ash in Cement grinding process. Dear All Experts, I have queries related to addition of Dry Fly Ash in cement grinding process as under:Where should we add the Dry Fly Ash in end discharge two chamber Cement mill Inlet or out let?

Option 3 Studies and Data on Silica Exposure and the Use ...

Concrete Grinding. 2010. Case Study to Identify Barriers and Incentives to Implementing an Engineering Control for Concrete Grinding Dust. This study examines the implementation of an LEV system on an overhead grinder illustrating the roles that various members of the construction team played. Concrete Grinding. 2010

Advances in Materials Science and Engineering Hindawi

Advances in Materials Science and Engineering is a peerreviewed, Open Access journal that publishes original research articles as well as review articles in all areas of materials science and engineering. ... Clinker modulus has always been used to control the production of Portland cement clinker. The compositional parameters of clinker ...

Optimizing the operation of the cement mill | Industrial ...

Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball mills implies high savings potentials. Parameters that hold potential energy savings are load level, revolution speed, combination of the ball charge, lining design and the adjustments of the separator. Standard optimization methods include meter sampling of the effective length ...

Impact of Different Grinding Aids on Standard Deviation in ...

grinding aids and to establish which grinding aid would produce the least standard deviation suitable for easier ... Cement meal pellet produced with graphite and lithium borate produced % residue on 45 µm which is less ... Cement control process parameters improved and quality control with the grinding aid mixture produced larger

CO Accounting and Reporting Standard for the Cement Industry

emissions: the Cement CO 2 Protocol. While accounting for the specific needs of the cement industry, the protocol was closely aligned with the overarching greenhouse gas protocol developed under a joint initiative of the WBCSD and the World Resources Institute (WRI). This second, revised edition of the Cement .

Peak cement‐related CO2 emissions and the changes in ...

The cement industry is the primary source of process‐related CO 2 emissions in China and worldwide. This industry contributed 11% of the total emissions in China. As the cement industry is regarded as one of the key energy‐intensive manufacturing sectors, greater attention should be paid to its sustainable production and emission control.

vertical roller mill operation and parameters Solutions ...

Operational parameters affecting the vertical roller mill . Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. operational parameter for vertical roller mill

Cement Grinding Technology

Cement Grinding Technology Lixhe / Liège, Belgium, 67 November 2018 Agenda All details are subject to change. 2 7 November 2018 (Pentahotel Liège) 09:00 Welcome and introduction Philipp Fleiger/ Stefan Seemann, ECRA 09:15 New experiences with high fineness separation Florian Grassl PMTechnologies

Contents

6 Cement Plant Operations Handbook – Sixth Edition Contents Section A – ProceSS SummArieS 1. Introduction10 1. The basics of cement manufacture – 2. History of cement manufacture – 3. Portland cement in today's world

Elbahlul M. Alghadafi and Muhammad Latif

grinding process. Portland cement may be grey or white, but blends can be generated based on the two products. Cement is the major component of concrete. Concrete is an artificial rock, a material made from a proportioned mix of hydraulic cement, water, fine and coarse aggregates, air [6], and sometimes additive concrete can also be made from a ...

ENVIRONMENT IMPACT ASSESSMENT FOR SECIL .

The following environmental parameters were analysed for this study: climate, geology, soil, hydrology and water quality, waste, air quality, noise, ecology, landscape, heritage, ... Secil Lobito has a grinding capacity of approximately 270 000 tonnes of cement but it has no clinker production. Therefore, the cement ... Cement grinding; j ...

Optimizing the control system of cement milling ...

Information about the openaccess article 'Optimizing the control system of cement milling: process modeling and controller tuning based on loop shaping procedures and process simulations' in DOAJ. DOAJ is an online directory that indexes and provides access to .

Latest Posts

- مصنع كسارة مخروط محطم

- ديبا ستون محطم آلة الصانع

- تستخدم كسارة الفك سفيدالا

- محمل كسارة الصخور

- آلة صنع الرمل الاصطناعية من ألمانيا

- آلة طحن مطحنة الكرة في الأردن

- المعدات المستخدمة في صناعة كسارة التعدين

- آلة غسل الرمال في التعدين

- عملية إنتاج الأسمنت خطوة بخطوة

- المسار كسارة شنت المصنعين من المملكة العربية السعودية

- كسارات متنقلة من السعودية

- كسارة حجارة المحجر في الجزائر

- فحم بخاري فحم حجري

- الجرانيت المحجر سعر معدات

- مشترون من مصنع كسارة الحجر القديم في اليمن

- cost of setting up a small sugar mill in assam philippines

- gold mining equipment supplier coupon

- heavy duty grinding machine 17

- china şangay ball mill

- a quick guide to selecting sandpaper

- gold separator on youtube

- stone crusher plant in orissa price

- cone crusher rubbles

- hammer mill saller in tanzania

- double granding machine

- tool and cutter grinding machine price pakistan html

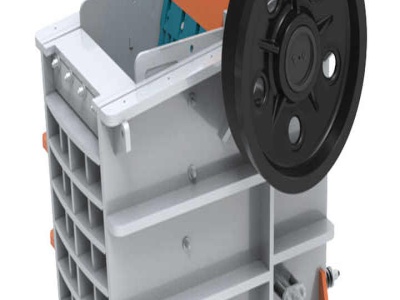

- singel jaw crusher pe

- blueprints building a rock crusher free

- coedmore quarry stone

- histroy of some miningpanies