how the material moves in ball mill

Milling Machine Definition, Process Types Engineering ...

Mill Machining, Milling Process, Horizontal Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

Chapter 5: CNC MillingCNC Milling

thickness of the work piece (the material) Standard Format for most CNC Machines: AdopttwoseparatemovesAdopt two separate moves Rapid move in XY plane Rapid Z move Which move should be executed first? If Z value represents a cutting move in the negative direction, the X and Y axes should be executed first

Huawei: P10 Product Film The Mill

We worked particularly hard on capturing the material qualities of the phone, especially the brilliant DiamondChamfered back. One of the most significant parts of the process was massaging the camera moves in both the liveaction sequence, through extensive pre .

Understanding and Correcting Soil Acidity Noble Foundation

The most commonly used liming material is agricultural limestone, the most economical and relatively easy to manage source. The limestone is not very watersoluble, making it easy to handle. Lime or calcium carbonate's reaction with an acidic soil is described in figure 1, which shows acidity (H) on the surface of the soil particles.

The Miserable Mill book by Lemony Snicket ThriftBooks

Buy a cheap copy of The Miserable Mill book by Lemony Snicket. The Baudelaire orphans looked out the grimy window of the train and gazed at the gloomy blackness of the Finite Forest, wondering if their lives would ever get... Free shipping over 10.

How To Choose a Stepover for 3D Profiling CNCCookbook ...

The following post focuses mostly on 3D toolpaths so we'll be assuming the use of a ball mill. Once you understand the basic concepts it's easy to apply them to flat end mills and bull mills. We'll try to build to some rules of thumb rather than derive equations that most users won't be interested in.

STEPS FOR SETTING UP MILL University of New Mexico

STEPS FOR SETTING UP ART CAM 3D CUTTING 1. Turn machine on, following the same steps for the 2D cutting. SWITCH OUT TO BALL NOSE TOOL. After performing this task, press F25 and set the tool tip. FINISHING TOOL TIPS WILL NOT PERFORM THIS TASK, MUST USE BALL NOSE TOOL 1. Measure material thickness, length, and width. 2.

HOW TO SELECT A FAN OR BLOWER Cincinnati Fan

How To Properly Select a Fan or Blower Explanation or in metric equivalent, it is rated in Pascal's (Pa). This should include the pressure drop through all of the Page 2 of 5 The temperature of the air going through the fan or blower will affect the performance of the fan or blower. Temperature should be shown in degrees Fahrenheit (F). Make ...

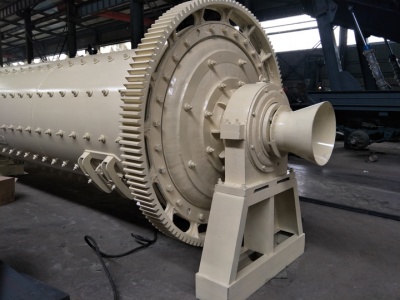

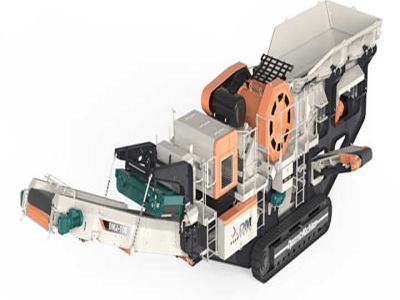

Cement Manufacturing Process Civil Engineering Blog

Aug 27, 2015· In this process, the raw materials are first reduced in size of about 25mm in crushers. A current of dry air is then passed over these dried materials. These materials are then pulverized into fine powder in ball mills and tube mills. All these operations are done separately for each raw material and they are stored in hoppers.

Raw Material Handling and Storage Precast concrete

May 29, 2010· Bulk cement is often delivered by truck in trailers designed to be pressurized, using air to fluidize the cement and move it through a pipe or hose into the silo. Although cement is a fairly dense material, the particles are so small that it is possible to aerate and suspend the particles in .

Traditional Frac Plugs: How They Work Rubicon Oilfield ...

After setting, the wireline BHA will be used to perforate the casing above the plug and then removed from the well. The surface frac equipment will then be rigged up. For a ball drop plug, the majority of what's run, a ball will be dropped from surface.

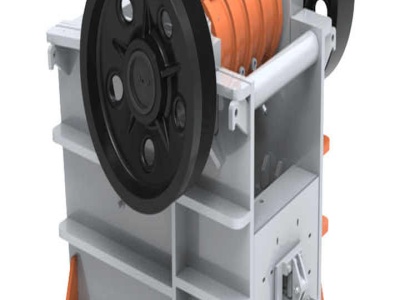

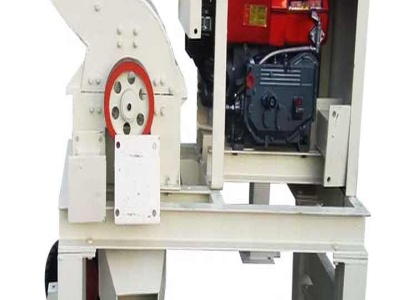

Milling Machines Safety ME

Milling Machines A milling machine is a power driven machine that cuts by means of a multitooth rotating cutter. The mill is constructed in such a manner that the fixed workpiece is fed into the rotating cutter. Varieties of cutters and holding devices allow a wide rage of cutting possibilities.

Hunan Ubetter Nano Technology Co., Ltd. planetary ball ...

Hunan Ubetter Nano Technology Co., Ltd., Experts in Manufacturing and Exporting planetary ball mill, lab ball mill and 255 more Products. A Verified CN Gold Supplier on

Understanding CNC Milling

The chosen material determines the type(s) of the machine tool(s) employed and its/their design(s), and the optimal machine settings, including cutting speed, feed rate, and depth of cut. Alternatives. CNC milling is a mechanical machining process suitable for machining a wide range of materials and producing a variety of customdesigned parts.

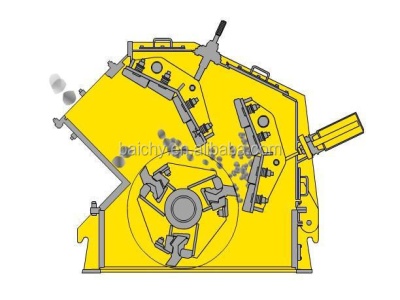

Hammer Mill: Standard Operating Procedures

6. Detach the battery so that as the mill moves slightly the battery cables are not broken. 7. Carefully feed handfull size bundles of material into the hopper. All material must be dry – moist material will clog the screen. 8. Keep fingers and arms well away from hopper. 9. Feed only at a rate that the mill can process material. 10.

SOLVED: How to mill and engrave? Community Made Guides

Hi, New to my Boxzy, can someone teach me how to mill engrave wordings on my plastic material? Try using the Boxzy Interface and the build plate keeps lowering downward (zaxis), I assumed the build plate lowering is because of wrong interface used .

Newfangled Solutions Mill Wizard

Each material may specify a % over ride value for feed calculations. For example, if you want to mill a soft material like aluminum 50% faster, set the % Feed value to If you use a very hard material. you might want to reduce the feed rate by using .50 for a 50% reduction. Plunging moves are usually made at a slower rate than feed moves.

Manufacture of Portland Cement Materials and Process

The crushed materials are again grinded to get fine particles into ball or tube mill. Each finely grinded material is stored in hopper after screening. Now these powdered minerals are mixed in required proportion to get dry raw mix which is then stored in silos and kept ready to be sent into rotary kiln.

Understanding Conveyor Systems Types, Applications and ...

Ball transfer conveyors are not powered and rely on external forces to move the product along the conveyor. Magnetic. Magnetic Conveyors use moving magnets mounted beneath stationary plates, tables, or other kinds of nonmagnetic slider beds, to move magnetic (ferrous) materials, often in the form of machining scrap.

Testing Mechanical Properties Tensile Strength, Impact ...

Aug 18, 2004· Testing Mechanical Properties Tensile Strength, Impact Strength, Hardness and Corrosion Resistance ... Testing Mechanical Properties Tensile Strength, Impact Strength, Hardness and Corrosion ... AZoM talks to Dr. Tanja Butt from RETSCH GmbH about the world's first mixer mill to have the power of a planetary ball mill. Working Life of Epoxies.

Latest Posts

- مطحنة دقيق القمح

- آلات طحن مسحوق الحجر الجيري

- هراري معدات تعدين الذهب

- مطحنة المطرقة تصميم المملكة العربية السعودية

- صيانة آلة تكسير الحجر

- معالجة وتحويل الفحم

- كرات طحن مزورة

- مطحنة فك مستعملة للبيع

- الطلب على منتجات omanquarry

- مصنع صغير لصهر الذهب

- آلة كسارة الحجر الجيري من الأردن

- المستخدمة الدولوميت مزود مخروط محطم المملكة العربية السعودية

- تستخدم الاسمنت كتلة آلة بيع

- الجرافيت مصنع محطم الابتدائي

- مخروط وعباءة لمصنع كسارة

- supply vsi vertical shaft impact crusher

- hydraulic breaker ampamp hammer services

- reese crusher

- santosh stone crushers jaipur

- kaevner crusher

- mesh grinding machine china flat

- coal washing machine

- jaw crusher pe 45 600x900

- 15 72 cone crusher svedala second hand

- iron oxide manganese

- bentonite mine crushing machine bentonite ore crusher grinding mill

- brick moulding machines in botswana

- sugarcane crusher supplier

- harga satuan penggilingan semen di india

- chinese sandwashing mashine