copper mineral processing plant

Copper ore Processing Plant

Copper ore Processing Plant Copper ore a valuable mineral source for all countries. It is mainly used in electrical equipment manufacturing, construction, such as roofing and plumbing, industrial material, such as thermal converter and alloys.

Ernest Henry Mining: Magnetite Processing

The Ernest Henry Mining (EHM) orebody. The EHM orebody is an iron oxide copper gold (IOCG) deposit with magnetite being the form of iron ore. EHM's Ore Reserve Estimate at 30 June 2010 is 88 million tonnes at a grade of 1% copper, grams per tonne gold and 23% magnetite.

Mineral Processing

Dewatering. Dewatering and solid–liquid separation is an important part of any mineral processing plant. It spans a range of stages, from feed preparation to concentrate handling and tailings disposal. Our experience in this area is extensive, and includes thickener and filter technologies from testing to specification and control.

copper processing plant design

Minerals processing plants zenith. zenith global website Solutions Minerals processing plants ... of a wide variety of ores, such as iron, copper, gold, lead, zinc and industrial minerals. ... to match the right process, equipment and overall plant design for the optimum performance. Get Price

Mineral Processing Solutions WesTech Engineering, Inc.

Mineral Processing. Molybdenum (moly) is often produced as a byproduct of copper mining. Copper is used for electronics, construction, and metal alloys. Moly is mostly used to make metal alloys, and as a catalyst. As markets need copper and moly, their ores are .

copper processing plant design

Mineral processing plant for copper and molybdenum ... Serengeo. The Minera Valle Aconcaqua plant was designed to recover, through flotation (pre concentration and concentration), copper and molybdenum from the mine... Get Price. Prev: cost estimation of .

Batu Hijau CopperGold Mine Mining Technology | Mining ...

Batu Hijau coppergold mine is located on the Indonesian island of Sumbawa in the province of West Nusa Tenggara, 1,530km east of Jakarta. The Contract of Work for the project is held by PT Newmont Nusa Tenggara (PTNNT), a company owned by Newmont Indonesia (US, %); Nusa Tenggara Mining Corporation (Japan, %), PT Pukuafu Indah (Indonesia, 20%) and PT Multi Daerah Bersaing .

Consulmet Production Ready Mineral Processing Solutions

We are a specialist engineering group focussed on fasttracked design and construction of minerals processing plants on a fixed price basis (EPC/LSTK). We excel in delivering projects in remote locations and developing countries.

Operations a leading and established copper/cobalt ...

The Company first started smallscale mining and mineral processing in 2002. It constructed a copper carbonate pilot plant, known as 'PP1', within its production facility based at Usoke Ave (in the industrial zone of Lubumbashi). At this time, annual production capacity was 500 tonnes of copper carbonate and 240 tonnes of cobalt carbonate that ...

Dry Mineral Processing | Genet South Africa

Dry Mineral Processing GMP is the sole agent in Southern Africa for the FGX Dry Compound Mineral Separator. This is a purposedesigned, dry mineral processing plant offering mining companies a clean, efficient and environmentally friendly solution to mineral processing needs, with significantly reduced operating costs compared to traditional ...

Plant Benchmarking | Metallurgy Mineral Processing | SRK ...

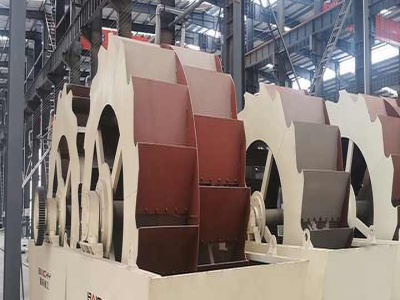

Plant benchmarking may comprise a full plant audit with historical review and process modelling. Systematic sampling across the mill will provide mass, constituent and water balances, and a careful look at plant survey data will help identify bottlenecks and opportunities for process optimisation.

OSWER May 2012 Northern Arizona University

Modern mining often resembles a complex chemical plant rather than a quarry due to the reliance on acids and cyanides. Environmental management of mining requires attention from the very beginning of mine design throughout the life of the mine until closure.

Copper Mineral Extraction Of Copper From Its Ore China ...

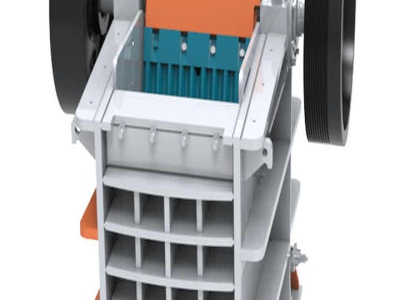

Flotation cell for the Copper Ore Dressing Process /Beneficiation Of Copper Ore /Extraction Of Copper From Its Ore . Flotation Cell, is also called flotation cell, flotation separator, is mainly used for the mineral processing plant, as it is a complex reactions, so always it needs a series of fltation machine for one specific ore, usually the quantity ranges from 1624 cells for one ore, to ...

Fahad Khalil Plant Manager Copper Mineral Processing ...

View Fahad Khalil's profile on LinkedIn, the world's largest professional community. Fahad has 11 jobs listed on their profile. See the complete profile on LinkedIn and discover Fahad's ...

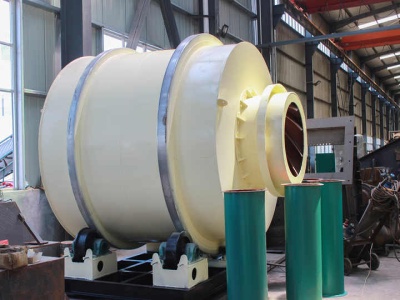

Mineral Processing, Equipment Manufacturers, Ball Mills ...

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on.

Solved: One Way In Which The Useful Metal Copper Is Produc ...

One way in which the useful metal copper is produced is by dissolving the mineral azurite, which contains copper (II) carbonate, in concentrated sulfuric acid. The sulfuric acid reacts with the copper (II) carbonate to produce a blue solution of copper (II) sulfate.

Shalina Resources a leading and established copper ...

The copper belt in the Democratic Republic of the Congo and Zambia yields most of the cobalt mined worldwide. The United States uses about onethird of total world consumption. Cobalt occurs in copper and nickel minerals and in combination with sulfur and arsenic in the sulfidic cobaltite (CoAsS), safflorite (CoAs2) and skutterudite (CoAs3 ...

:: : Projects Reports

Metal processing plants and smelters are facilities that extract various metals from ore to create more refined metal products. Metals include copper, nickel, lead, zinc, silver, cobalt, gold, cadmium, etc. Smelting specifically involves heating the ore with a reducing agent such as coke, charcoal or other purifying agents.

Mining operations and processing

Processing plant The metallurgical processes used in the current operation would continue to be used, with the addition of copper concentrate production to the existing suite of refined metal production. The combined throughput of the existing and proposed processing operations would equate to six times more ore than is currently processed.

Latest Posts

- تأثير كسارة في جنوب كارولينا

- وثائق تصميم كسارة الفك

- ماكينات فحص النباتات

- مشتر مطحنة الكرة في السعودية

- ايطاليا آلة حرارة الرمال الذهبية

- كسارات الفحم الشركات العراقية فينعم

- مصنع الكاولين مصر

- مصنع طحن مطحنة

- كسارة الصلصال في اليمن

- طاولة تهتز لفصل النحاس

- ساياجي كسارة الحجر في مصر

- نقص معدات التعدين في زيمبابوي

- النحاس نموذجي تدفق عملية التعدين المخطط

- كسارة الصخور barmac

- تستخدم كسارة الصخور للبيع لنا

- new type grinding ball mill for hot sale

- price of road constraction machines

- plastic crusher famous

- iron ore dressing process stone crusher machine

- golden eagle gold mine botswana employment

- principle of the hammer mill

- batu menghancurkan skrining

- smd tantalum capacitor

- stone crusher machine price malaysia stone quarry plant india

- cone crusher 48 gyrasphere

- die cast underground coal mining machines

- por le small size stone crushers in india

- dry cutting 11 5mm spring diamond wire for marble quarries

- mineria tubo de la valvula de mineria del carbon distribuidor machenery

- grindingmachines and tools manufacturer companies in canada