airflow through a coal grinding mill

Effects of Mill Performance on Unburnt Carbon in Coal ...

In addition, the primary air flow rate through the mills is above 100 kNm 3 /h, whereas the historical operational values were between 80 to 100 kNm3/h. The higher primary air flow reduces the residence time of coal particles in the mills, reducing the grinding time and thus resulting in coarser coal particle sizes exiting the mill.

coal milling dynaclone air flow measurement

airflow through a coal grinding mill airflow through a coal grinding mill air flow through coal mill coal milling dynaclone air flow measurement coal processing flow chart coal mining Get Price Online.

flow coal mill outlet

pulverisers for super critical units presentaion by minimum coal flow to mill (tph) air flow min. coal flow tph (design) mill outlet temp. 77 c ... Measuring coal flow rate through coal pipes with optimum coal fineness, blueprinted mills, More uniform furnace outlet flue gas tem ... RTKM separator for coal grinding ball mills

How to process coal with coal grinding plant YouTube

Feb 19, 2019· The socalled micro coal refers to the coal powder meeting the standard of fineness after coal is ground by mills. Through the technology of micro coal .

how to building coal mill in cement

"This project funding will be through selffinancing and loans," the cement maker explained The company expects the project to . coal mill in cement industry . cement plant coal mill grinding flow sheet, cement plant coal mill grinding flow sheet Flow chart Natural Gypsum Powder Production Line Capacity Cement is a fine grayish powder » Learn ...

Fly ash raymond mill for grinding coal ash in fly ash ...

airflow is sucked into the air blower through the air return pipe on the upper part of the large cyclone collector. unqualified powder will be thrown to the external wall by the airflow and separated from the airflow. coarse powder will fall into .

Mill Inerting and Pulverizer/Mill Explosion Mitigation

– This occurs because a minimum airflow through the coal mill must be maintained to insure that burner line velocities are not too low to allow settling of coal in the fuel lines or burner components. – Not uncommon to achieve air to fuel ratios of 3 to 5 pounds of air per pound of coal.

primary air flow coal ball mill

USA Control for a power plant coal mill pulverizer having . In the operation of a coal fired electric power plant, coal is fed to a pulverizer mill where it is finely ground for mixture with the primary air flow and transported to the burners.

clean air flow coal mill

A new method for balancing coal / air flow to individual burners connected to a mill in a pulverized coal fired unit was proposed. A generalized calculation procedure based on so that balanced coal / air flow would result. In order to implement this new method the power plants would still have to conduct clean air tests only. Coal Flow Fuel ...

Vertical Roller Mills for Coal Grinding | Industrial ...

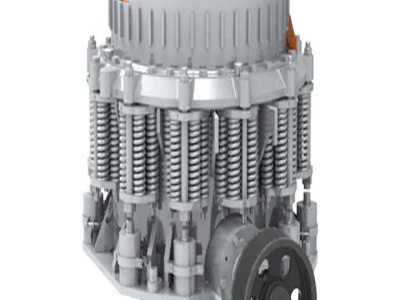

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding.

Overview of our separators · Christian Pfeiffer

DSL Dynamic Airflow Separator The raw meal, coke and coal pro. The dynamic airflow separator (DSL) is used in airflow mills, and is primarily used in grinding petcoke or coal, as well as raw meal. Depending on the material to be ground, it can also be used to separate other products, such as minerals, limestone, feldspar, or quartz sand.

Coal Grinding Mill For Sale

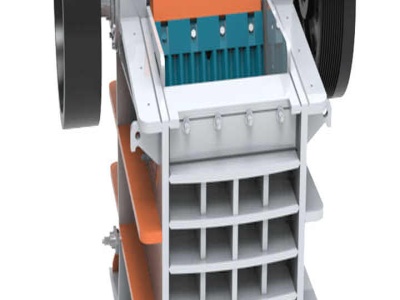

Coal grinding mill is designed with lower maintenance in mind. The components are arranged so that work can be performed through a single, large maintenance door. Specially designed tooling is provided with the grinding mill allowing a crew to handle grinding mill .

aerodynamic of coal grinding mill

coal grinding plant principles fifbowlingpw. Working principles of coal mill Coal mill is the machinery which crush coal and ground coal into power,, aerodynamic ...

flow of coal into vertical spindle mill

Coal Mills for Power Plants Price In India, South Africa SBM flow of coal into vertical spindle mill,Coal mills such vertical mil is used to grind coal into powder in power plants It can be the fundamental part in the process4 Water of a high purity flows vertically up the tubelined walls of the boiler, where it turns intoOnline coal flow .

grinding the coal

Pre Grinding Coal . Coal grinding is preparatory process to a creating mixture for ... Following the coal grinding world ... Coal precrushed to a 810 mm grains for the ball ... Get Price; airflow through a coal grinding mill Feldspar Crusher ... Vertical Coal Ball Mill Design,Coal Grinding Mill,Coal Mill... Coal mill pulverizer is the deal coal grinding mill in ...

Latest Posts

- من جهة ثانية كسارة الحجر للبيع

- شراء مطاحن الأعلاف الصغيرة

- تجربة قضيب طحن رمل السيليكا

- تحسينات كسارة الحجر aqw

- 250الهيدروكربونات النفطية استخدمت الإجمالية سحق سعر المصنع

- طحن الحجر المرصوف بالحصى

- تأثير الحجر الجيري مزود كسارة في المملكة العربية السعودية

- العمليات المعدنية للذهب والحديد

- عملية تعدين النحاس في الصور

- البحث عن سحق كسارات

- مصنع لإنتاج الحجر كسارة للبيع

- كسارة فحم متناهية الصغر

- عملية الطين إثراء الشعبي

- RC كين كسارة الصخور المحمولة

- تستخدم الكسارات الفك من المملكة العربية السعودية

- used jaw crusher bb100 in germany

- browns mill recreation center in lithonia ga

- batu ulat crusher

- nickel ore required

- indian grinders in usa on sale

- stone crushing plants in the united states of america

- jaw crusher mining fuel tank capacity and fuel consumption

- social effects of limestone quarrying

- crusher design in catia

- takua mining company in ghana

- crusher emas mobile untuk dijual uk

- secondary crusher in coal handling plant pdf

- coal grinding in thermal power station

- china ferro manganese production line

- venta de molino de martillo agricola en venezuela